3D printer manufacturer Stratasys has been awarded a $20 million U.S. Navy contract, the largest of its kind that the company has ever received.

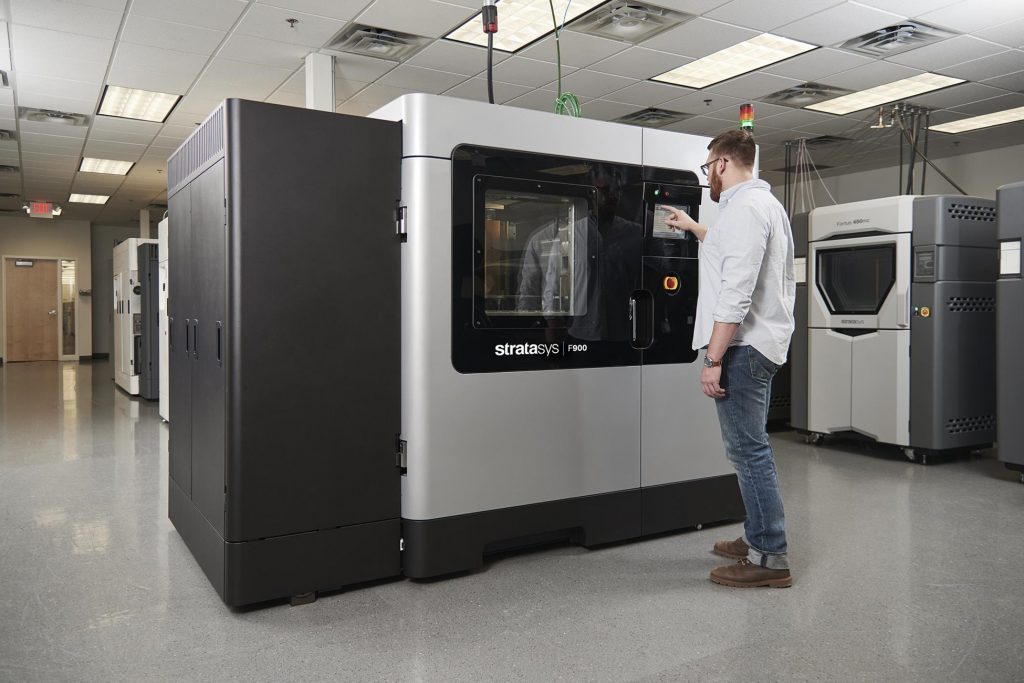

Set to be fulfilled over the next five years, the deal will see Stratasys supply up to 25 F900 3D printers to the U.S. Navy, in addition to the materials, support and training needed to run them. According to Mark Menninger, Director of Stratasys’ U.S. Government Business division, the move could serve to shorten U.S. Military supply chains, while providing its Navy with enhanced aircraft repair capabilities.

“The benefits of AM for military organizations like the U.S. Navy include cost-effectively extending the life of strategic and tactical assets like aircraft while ensuring sustainment activities can happen quickly and from virtually anywhere,” said Menninger. “This contract, the largest government project for Stratasys to-date, continues to expand the presence of industrial 3D printing from Stratasys across the U.S. government.”

The DoD’s 3D printing strategy

Stratasys’ newly-announced naval contract follows the launch of the U.S. Department of Defense’s (DoD’s) additive manufacturing strategy earlier this year. Drafted alongside other U.S. military services and defense agencies, the blueprint effectively outlines five goals the department is seeking to achieve through the adoption of 3D printing in defense.

To best achieve these aims, which primarily involve modernizing U.S. national defense systems, improving equipment upkeep and enhancing warfighter readiness, the DoD has already set itself some short-term goals. For instance, the agency has committed to releasing extensive internal policy guidance that allows 3D printing to be adopted within defense to the “widest practical extent.”

The DoD has also made plans to establish a Joint Defense Manufacturing Council, to facilitate the sharing of such information, and reiterated its intention to provide specific training on advanced technologies to its personnel moving forwards.

Since publishing its strategy in January 2021, the DoD has continued to ramp up its adoption of 3D printing, and just a month later, it contracted ExOne to develop a ‘portable 3D printing factory.’ Designed to be housed inside a 40-foot shipping container, the system is being built to provide military personnel with everything they need to 3D print spares on land, in the air or at sea.

On the software front, the DoD has also backed defense-related upgrades to Senvol’s machine learning platform. Although the extent and value of the deal, as well as the specifics of the software’s R&D remain undisclosed, it’s understood to involve developing ‘additional capabilities’ for the technology, when it comes to qualifying 3D printing materials and processes.

Now, with its $20 million Stratasys order, the DoD has chosen to expand its printer portfolio as well, particularly at its U.S. and Japanese bases, where the first eight systems are set to be shipped by the end of 2021. Once there, the machines will be used for producing end-use parts, tooling and training aids, as well as contributing to the Navy’s aircraft maintenance and distributed manufacturing programs.

Stratasys’ F900 in aerospace

Launched back in April 2018, Stratasys’ F900 Production 3D printer builds on its Fortus 900mc platform, with a larger build volume and heightened accuracy, that enables it to address a wider range of applications. In particular, the machine’s compatibility with flame-retardant materials like ULTEM 9085, has increasingly seen it deployed to produce parts that meet stringent aerospace regulatory criteria.

Last year, for instance, BAE Systems announced the installation of its fourth Stratasys F900 system, as part of its ‘Factory of the Future’ initiative. Now in operation at the firm’s UK-based Samlesbury site, the machine is being used to fabricate prototypes, tooling and end-use parts for its fighter jets, in a way that has reportedly yielded “significant cost and lead time reductions.”

Stratasys also received one of its largest ever aerospace orders in August 2020 from Latvian 3D printing service provider AM Craft. The customer’s four-F900 order effectively doubled its print capacity, and has since allowed it to manufacture aerospace-certified interior aircraft parts including seating, panelling and ducting for its aviation-centric client base.

The U.S. Navy’s AM ambitions

Aircraft maintenance aside, the U.S. Navy has also invested heavily in investigating 3D printing’s distributed manufacturing potential, with the aim of accelerating the way it supplies deployed forces. Earlier this year, the U.S. Naval Postgraduate School revealed that it was testing the potential of Xerox’s ElemX 3D printer, particularly as a means of achieving greater supply chain flexibility.

In a similar vein, 3D printing software developer 3YOURMIND has recently been contracted by the Naval Information Warfare Center (NIWC) to develop a new seamless ‘digital production’ workflow. Through this cyber network infrastructure, the NIWC is aiming to establish a digital thread that allows it to remain vigilant and rapidly respond to threats at all times.

Elsewhere, engineers at the U.S. Navy Research Laboratory have 3D printed novel antenna components that could help improve the U.S. Navy’s wider radar monitoring capabilities. By adopting additive manufacturing, the team say they’ve been able to create their lightweight arrays more quickly and cheaply than conventional production methods allow.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows two U.S. Naval warships under a map of the world. Image via 3YOURMIND.