Engineers at the US Navy Research Laboratory (NRL) have deployed a 3D printer to fabricate optimized antenna components that could be key to advancing the US Navy’s radar monitoring capabilities.

Utilizing 3D printing, the engineers were able to create cylindrical arrays at a lower cost and with reduced lead times compared to those incurred using conventional specialized equipment. The resulting parts also proved to be significantly lighter than previous iterations, potentially lending them new end-use navigational or defense applications.

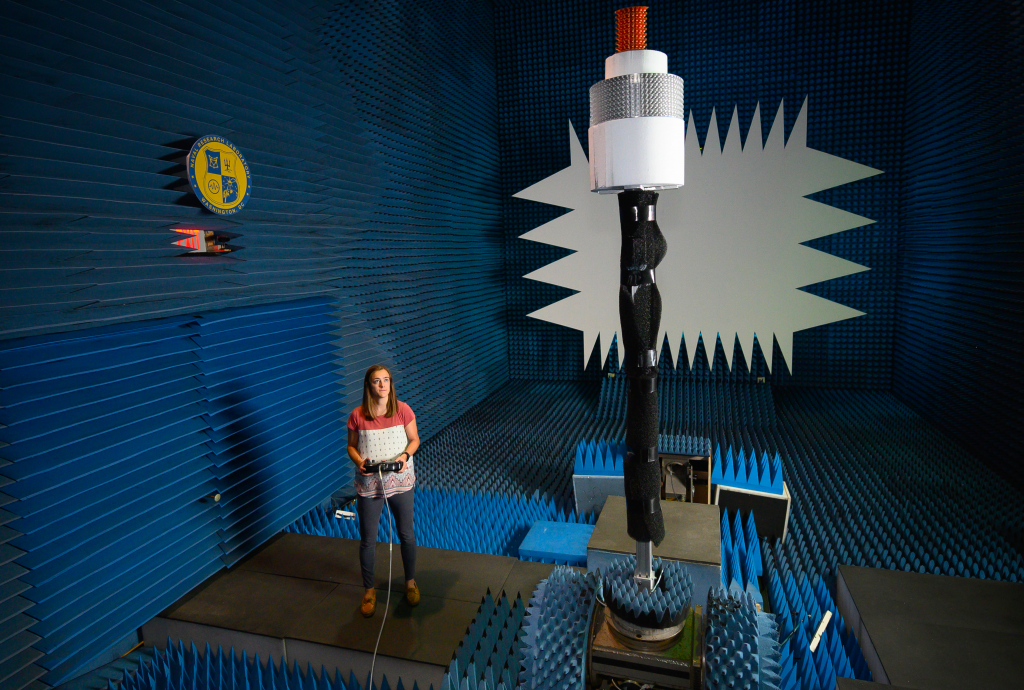

“3D printing is a way to produce rapid prototypes and get through multiple design iterations very quickly, with minimal cost,” said NRL electrical engineer Anna Stumme. “The light weight of the printed parts also allows us to take technology to new applications, where the heavy weight of solid metal parts used to restrict us.”

Servicing naval antenna arrays

While operating at sea, naval ships rely heavily on their radars, not only as a means of maritime navigation, but monitoring the movements of potential aggressors from a distance. These critical systems are powered by arrays composed of interconnected antennas, but they are often subject to breakage, necessitating their rapid replacement.

At present, such stopgap parts are either ordered or intricately machined from metal, a process that can take weeks to complete. Using a 3D printer on the other hand, Stumme and her NRL colleagues found that components like cylindrical arrays can now be fabricated in a matter of hours, due to the reduced machining and assembly time required.

However, while foreign defense forces such as the Dutch Navy have adopted INTAMSYS 3D printing to fabricate spares on-demand, the NRL don’t consider this to be realistic yet. In fact, the engineers maintain that the technology has greater potential in rapidly iterating new designs, something they’ve put to good use with their novel antenna array.

“We are not trying to say that we need to 3D print everything and put it on a ship because that is not realistic,” explained Stumme. “We don’t necessarily know how it would hold up in that environment. For us, it’s a way to test more design iterations in a short amount of time.”

3D printing the NRL antennas

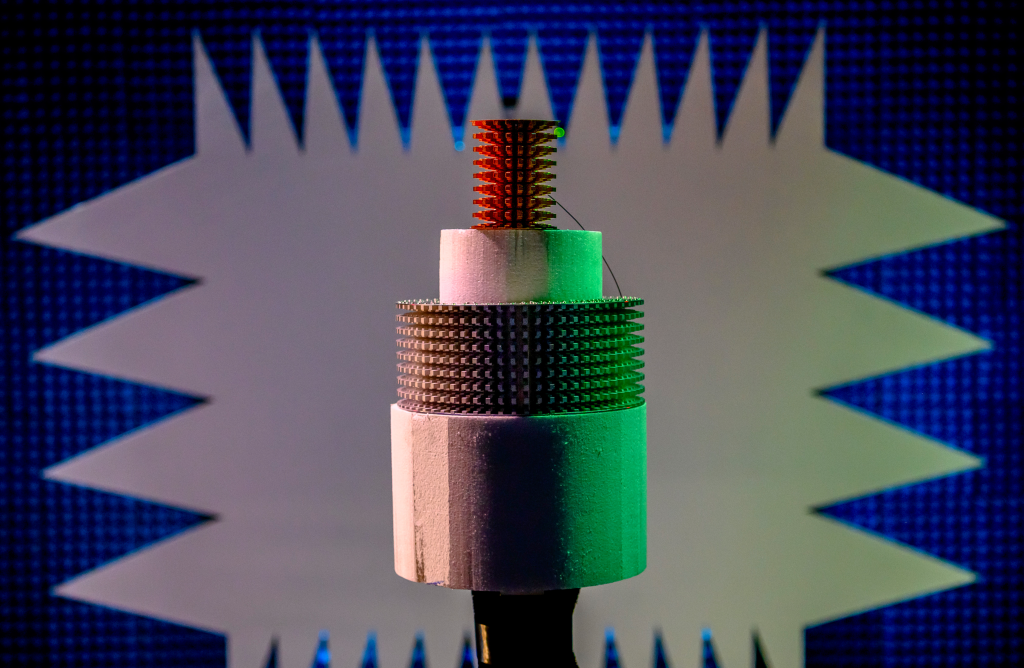

Having won a prize for their initial research at the 2019 Antenna Applications Symposium, the NRL team chose to investigate how 3D printing could be used to optimize the weight of related parts. To begin with, the engineers fabricated a set of nylon prototypes, before electroplating them at the lab’s Autonomous Systems Research facility.

During the process, the researchers were able to add a thin metal layer to each part, providing them with the conductive surface necessary for relaying applications. Once ready, the prototypes underwent surface roughness characterization tests, which effectively allowed the team to assess the impact of exterior finish on their performance.

“Surface roughness is important for waveguides and antennas because it can cause scattering losses and result in a less efficient antenna,” explained Nick Charipar, Head of the Applied Materials and Systems Section. “Antennas radiate and receive waves. So if a wave runs along a rough surface it is distorted and the energy may not go where you want it to go.”

After the initial tests, the NRL’s Radar Division installed the components to see how they affected radar functionality, finding that each 3D printer’s characteristics affected the device’s performance. As a result, the team concluded that if an optimized parameter set can be identified, then spare arrays could be rapidly produced anywhere in the world.

Later this year, Stumme and the NRL crew intend to conclude their study with a field test of a prototype cylindrical array aperture, integrating it into an X-band surveillance radar. The arrays, which are used to provide 360o visibility to small ships, will be 3D printed using lightweight optical fibers, potentially granting them enhanced thermal performance.

The U.S. Navy and printing at sea

The US Navy has long recognized the potential of 3D printed parts, and invested heavily in both researching them and their end-use application.

Most recently, the US Naval Postgraduate School (NPS) became the first to install Xerox’s new ElemX Liquid Metal 3D printer. The NPS has effectively entered into a collaboration with Xerox that will see it attempt to develop new ways of fabricating parts on-demand for deployment across the US Armed Forces.

The U.S. Navy’s Naval Sea Systems Command (NAVSEA) division has also awarded funding to seven R&D programs that could yield cost savings of $250 million. At an initial outlay of just $8.2 million, the part optimization initiatives potentially represent a highly efficient way of reducing the maintenance needed onboard naval vessels.

Elsewhere, scientists based at the Naval Surface Warfare Center have developed and patented a novel biodegradable 3D printing material. The team believe that their new polymer could be deployed in future to create underwater equipment such as unmanned or autonomous underwater vehicles (UUVs).

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Anna Stumme making adjustments to an antenna array inside the anechoic chamber at the NRL. Photo via the NRL.