3D printer manufacturer 3D Systems has been chosen by aerospace firm Raytheon Technologies and the Combat Capabilities Development Command (CCDC) of the Army Research Laboratory (ARL) to take part in a research project that aims to develop topologically optimized heat exchangers for the US Army through additive manufacturing.

Alongside Raytheon, 3D Systems will be working with the Penn State Applied Research Lab, John Hopkins University, and software firm Identify3D on the project, which was awarded through the National Center for Manufacturing Sciences’ (NCMS) AMMP program.

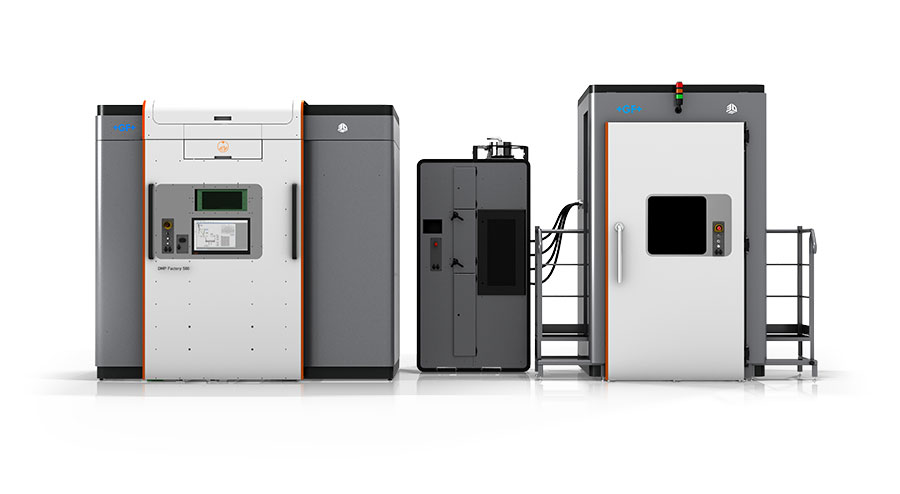

3D printing will be deployed across the entire part lifecycle, including determining performance requirements, design optimization, manufacturing the part, and quality control and validation, with 3D Systems’ DMP Factory 500 3D printer used to build the components during the project.

Dr. Brandon McWilliams, Deputy Program Manager at the CCDC ARL Weapons and Materials Directorate, said: “The novel integration and concurrent design of structures, materials, and processes to create topologically optimized heat exchangers will enable disruptive advancements in munitions technology in support of multiple army modernization priorities.”

The bespoke DMP Factory 500 3D printer

3D Systems first launched its DMP Factory 500 automated metal 3D printing system at the 2018 International Manufacturing Technology Show, equipped with a large 500x500x500mm build volume and high throughput enabled by multiple lasers. The firm’s Application Innovation Group (AIG) has designed a bespoke version of the DMP Factory 500 for the ARL project, equipped with modules designed to meet the unique requirements of the heat exchanger applications.

Using the DMP Factory 500, the team has been tasked with designing, manufacturing, and optimizing a component with the ability to maximize cooling and improve overall system performance of army modernization products. The project will address the entire lifecycle of the thermal application, from determining performance requirements and topologically optimizing the design, to manufacturing the part on the DMP Factory 500 and process monitoring for quality control. The heat exchanger’s performance will also be validated, as will data security related to the manufacturing process.

“Our work with the Army Research Laboratory is taking 3D Systems’ technology in new directions,” said Chuck Hull, Co-founder and Chief Technology Officer at 3D Systems. “We’re able to combine our metal 3D printing innovation with unique advancements in process modeling and monitoring, data security, and topology optimization to deliver an unparalleled solution.”

The printing system was installed at Penn State’s Center for Innovative Material Processing through Direct Digital Deposition (CIMP-3D) in December, and will be powered by 3D Systems’ 3DXpert 3D printing software and LaserForm materials. The bespoke 3D printer will be upgraded with some of the technologies 3D systems is currently working on for its 9-laser, 1mx1mx600mm metal 3D printer, such as coaxial process monitoring and a single-lens reflex (SLR) camera within the build chamber. As a result, the development activity underway on the DMP Factory 500 will be directly transferable to the larger system.

3D Systems was awarded a $15 million contract by the ARL to develop the 9-laser printer, deemed to be the world’s largest metal 3D printer, which will be used to address the ammunition, ground vehicle, helicopter, and missile defense needs of the Armed Forces.

“The migration to larger build envelopes significantly expands the domain of Department of Defense applications addressable by additive manufacturing, yet it brings new challenges for process monitoring and quality control,” said Ted Reutzel, Associate Research Professor at Penn State’s Applied Research Lab and Director of CIMP-3D.

“The installation of this system at our center will enable our team to leverage prior developments – funded by the US Navy, US Air Force, America Makes, and others – to help meet these challenges and rapidly integrate advanced flaw detection technologies.”

Process monitoring and defect detection

Alongside designing and manufacturing the heat exchanger components, the team will also develop new technologies for process modeling and monitoring, and defect prediction and detection. The respective parties will additionally explore novel approaches to topology optimization and cyber-physical security throughout the project.

Identify3D will provide end-to-end data protection for the core manufacturing process, from build file generation to part production on the DMP Factory 500, and will seek to develop an architecture capable of securely collecting inspection and defect detection sensor data to optimize the digital workflow of the manufacturing process.

“The team is establishing a singular fluid architecture that encompasses design optimization, sensing, machine learning, security, testing, and production,” added Lisa Strama, President and CEO of NCMS. “This will result in a prototype based upon a holistic, machine agnostic, interconnected workflow.

“Leveraging the NCMS’ AMMP program and our trusted collaborative model, this project fully showcases the advancements made possible and efficiencies gained when bringing together OEMs, non-traditional defense contractors, and academia to address the full life-cycle of army relevant components.”

Recent 3D printing activity in the US defense sector

The US Army has often experimented with 3D printing through its ARL in recent years, with the ultimate aim of improving warfighter readiness and modernizing its defense systems. This month alone, the US Department of Defense (DoD) unveiled its first-ever comprehensive additive manufacturing strategy to broaden the adoption of 3D printing throughout the nation’s defense sector. The new strategy will build on the success of other additive manufacturing projects initiated by the US military, some of which include experimenting with 3D printed missile parts, re-engineering parts for its Black Hawk helicopters, and customized earplugs for personnel.

Most recently, GE Research was awarded a $14.3 million project by the Defense Advanced Research Projects Agency (DARPA) to develop a 3D printed device capable of producing water out of thin air, in a bid to transform how potable water is transported to troops out in the field. If successful, the portable device will be able to produce enough daily water for 150 troops.

Around the same time, the US Naval Postgraduate School (NPS) installed the latest 3D printer from global print and digital document corporation Xerox, the ElemX Liquid Metal 3D printer, at its university campus in order to explore the ways 3D printing could transform how the military supplies its forward-deployed forces.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the DMP 500 Factory 3D printing system. Photo via 3D Systems.