Additive manufacturing data specialist Senvol is set to develop its Senvol ML machine learning software with ‘additional capabilities’, following a new round of funding from the U.S. Department of Defense (DoD).

Senvol ML was originally launched back in November of 2019 after being awarded an STTR Phase II seed fund with the U.S. Navy’s Office of Naval Research (ONR). The new capital has been provided by both the U.S. Navy and the U.S. Air Force, from organizations such as the ONR, Naval Sea Systems Command (NAVSEA), Naval Air Systems Command (NAVAIR), and the Air Force Research Laboratory (AFRL). The size of the deal and the specifics of the software developments remain undisclosed.

“We are very excited about the continued support from several of our Department of Defense partners,” said Annie Wang, president of Senvol. “Our collective objective is to enable organizations to quickly characterise or qualify Additive Manufacturing materials and processes. The new capabilities that we are developing are quite compelling and will augment the Senvol ML software’s existing suite of capabilities.”

What is Senvol ML?

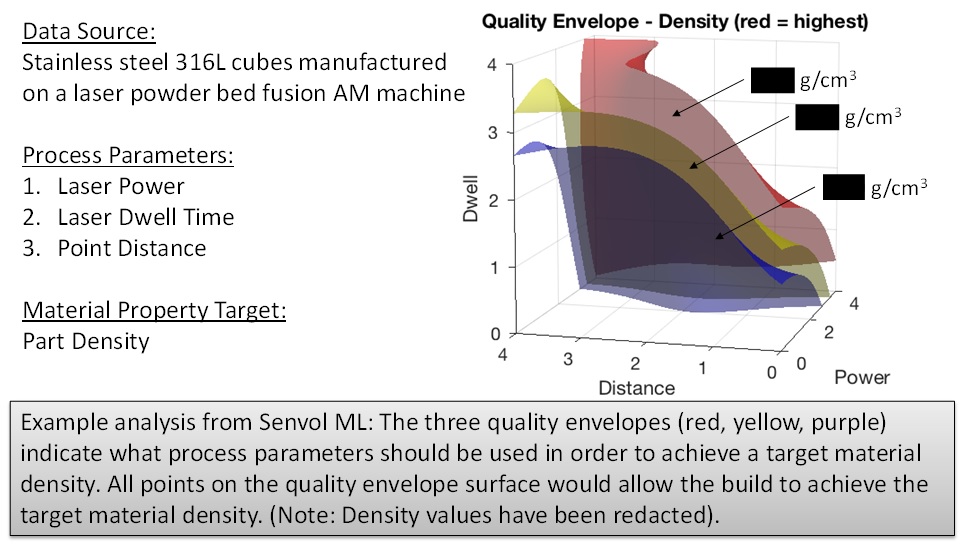

Senvol ML is a proprietary data-driven machine learning software that can be used to analyze the relationships between 3D printing process parameters and the performance of a material. By simply providing a target mechanical performance, users can automatically generate an optimized set of 3D printer-specific process parameters, eliminating the need for trial and error while significantly saving both time and costs.

With users in the aerospace, defense, oil and gas, medical, and automotive sectors, Senvol ML can be used to analyze additive manufacturing data from any system, any process, and any material. The program ultimately helps companies characterize and qualify their materials and 3D printing processes in a more rapid manner. Beyond just process parameter optimization, the software serves to predict material properties, generate insights from process monitoring data, and minimize data generation costs.

At the system’s core is a modularized ICME (integrated computational materials engineering) framework. The framework categorizes additive manufacturing data into four distinct modules: process parameters, material properties, process signatures, and mechanical performance. The algorithms that quantify the relationships between the four modules are what power the software.

ML-based 3D printing for the armed forces

Naturally, the DoD already has a significant investment in Senvol’s ML software, and has used the program for a number of applications over the past year. In November, the US Army Research Laboratory (ARL) awarded the company with a contract that will see Senvol ML used to design and qualify 3D printed components for use on missiles. As part of the project, Senvol will use its expertise to develop a flexible ‘qualification plan’ for the Army, ultimately reducing manufacturing costs and lead times.

Wang stated, “The significant increase in speed will allow the Army to support warfighter readiness by unlocking the full transformative potential that AM offers.”

Elsewhere, the Air Force has also previously used Senvol ML to produce large-scale aerospace parts on a multi-laser EOS SLM 3D printer. Initiated last summer, the project was focused on developing baseline mechanical properties and design allowables in a bid to optimize the production of end-use aircraft components.

Jessica Orr, a Program Manager at the University of Dayton Research Institute (UDRI), a project partner, added, “AM has recently demonstrated the ability to rapidly deliver complex geometries and production quality parts that are able to enhance the capabilities of DoD weapons systems. In this collaborative program we are developing and demonstrating a methodology to use a new multi-laser AM printer to produce airworthy, end-use parts.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a fleet of U.S. Air Force aircraft. Photo via Mikayla Heineck, US Air Force.