Markforged, a U.S. manufacturer of metal and composite 3D printers, has launched its new AI-based Blacksmith software for use with the X7 3D printer.

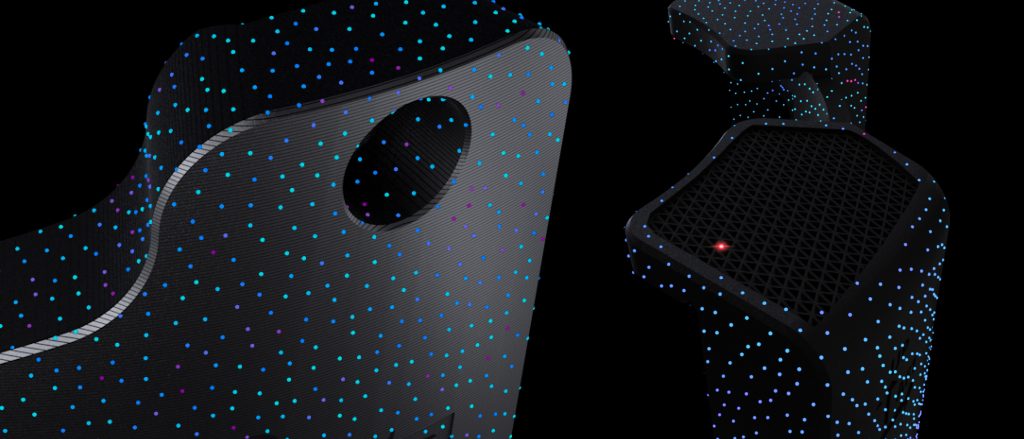

Leveraging the X7’s own existing laser micrometer and a patented scanning algorithm, Blacksmith accurately measures the dimensional precision of parts as they are being printed. This scan data is then cross-referenced against the intended design files, giving manufacturers the ability to assess just how close the printed part is to the original STL. It follows that the predictive nature of the machine learning platform can then be used to perform corrective actions on subsequent print jobs, improving process reliability over time.

Engineering system supplier Dana is among the early adopters. Kelly Puckett, senior engineering manager for additive manufacturing at Dana, explains, “Markforged’s Blacksmith enables the dimensional confirmation of additive parts straight off the print bed, giving engineers confidence that the parts are within spec prior to use. There is no need for secondary systems, additional equipment or separate databases for results – all of which help streamline workflows and get us to market faster.”

AI-based part inspection

Much like the company’s cloud-based Digital Forge platform, Blacksmith operates on a federated learning model across the entire fleet of Markforged printers. The software has the ability to learn from each print job via closed-loop processing, enabling it to improve the quality of 3D printed parts on a rolling basis. By gradually building up a centralized scan library of print quality data, users are able to more intelligently modify print parameters based on previous results.

Since the in-process part inspection system performs scans on every layer, complex inner structures which would otherwise be impossible to measure can also be captured with ease. As a bonus, Blacksmith enables organizations to compare single part printing data across multiple locations, which is crucial for multinationals that may have manufacturing facilities worldwide.

A spokesperson from aerospace firm Leonardo said, “We use Markforged printers to produce bespoke tooling solutions to build and maintain aircraft. The in-process inspection features of Blacksmith will allow the Central Tooling Team to confirm the accuracy of the printed part straight from the printer, without the need to inspect it manually afterwards. This will help speed-up delivery times and ensure that the tools produced meet the necessary requirements every time.”

The shift to autonomous manufacturing

Blacksmith is the next step in Markforged’s vision for autonomous manufacturing, whereby 3D printers are able to adapt their build parameters to account for unforeseen variables. Consolidating the part inspection workflow into the build itself is expected to make manufacturing facilities all the more cost- and time-efficient, all while alleviating the need for constant human supervision.

“We knew that it would only be possible to reinvent manufacturing with a software-first approach to building hardware,” said David Benhaim, CTO and co-founder of Markforged. “Blacksmith fundamentally changes the way engineers think about additive manufacturing. For the first time, they will have confidence that their parts will perform as expected without a time-consuming process. Blacksmith makes our platform smarter and is the next step on our roadmap to bring the agility of software to the world of manufacturing.”

Blacksmith is available now as a subscription service on all cloud-connected Markforged X7 3D printers. However, the company intends to expand the software’s compatibility to the entire portfolio of Markforged composite and metal systems.

The release comes following a merger agreement with blank check company one, which will see Markforged go public with its 3D printing business this summer. Once complete, the deal will result in a combined company valuation of $2.1 billion while netting Markforged up to $425 million in proceeds.

Elsewhere, the company is also helping a team led by the NASA JPL take on the Defence Advanced Research Projects Agency’s (DARPA) Subterranean Challenge. As part of the project, Markforged 3D printers will be used to help create fully autonomous robotic systems capable of traversing underground environments such as caves during planetary explorations.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a part being scanned by Blacksmith. Image via Markforged.