Remote 3D printing secured transmission service DEFEND3D has introduced a new patented technology to protect against cybercrime and IP theft during remote 3D printing.

Based on a One-Click-Print protocol, the technology enables a secure digital resupply of reproduction parts to remote locations without the need for file transfer. Instead, a continuous stream of production instructions is issued to the machine, secured by six levels of security, including encryption.

Rather than sending 3D files, DEFEND3D essentially allows a digital asset to be live-streamed to the 3D printer in real-time, providing only the vital information to be accessed before instantly deleting it.

The new technology has been tested by the UK Strategic Command, a division of the UK Ministry of Defence (MOD), with DEFEND3D providing a secure platform for digital manufacturing that links up a central design hub with multiple deployed locations.

“We assess this to be a game-changing capability, allowing us to overcome our current reticence of sending sensitive parts overseas, and allow us to send more parts wherever we wish in the world,” said an unnamed Lt. Col. from the MOD. “Being familiar with cutting edge 3D printing technologies, I believe this to be the only such system on offer.”

Cybersecurity risks in 3D printing

The storage and transfer of large streams of sensitive data have become commonplace within the digitized world of additive manufacturing. The technology’s increasing industrialization has seen 3D printers and manufacturing facilities become increasingly IoT-connected, and while this is convenient, it also gives rise to the threat of cybersecurity breaches.

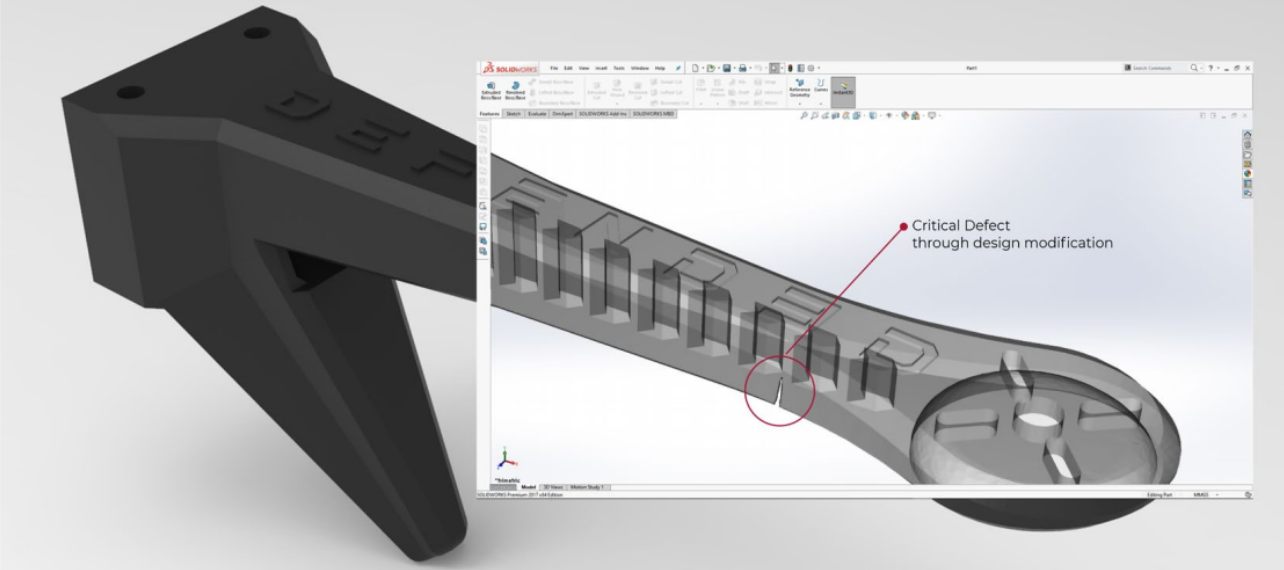

The main cybersecurity risks in 3D printing center around IP theft and process sabotage. For instance, cloud-based file-sharing systems may be hacked, email servers can be breached, and solid 3D printed parts could potentially be reverse-engineered using 3D scanning technology.

To demonstrate just how catastrophic process sabotage can be, researchers from Ben-Gurion University of the Negev, University of South Alabama, and Singapore University of Technology and Design have previously hacked into a 3D printer used to fabricate drone components. The team was able to make undetectable modifications to the 3D printed propellers of the drone that made it past quality assurance, and which compromised the integrity of the part.

Such concerns have recently been highlighted from a defense perspective, after the US Department of Defense’s (DoD) first official additive manufacturing policy came under scrutiny from a report issued by the DoD Inspector General. The auditor claimed the DoD’s 3D printers could be vulnerable to sabotage by hostile attackers, due to their access to the DoD’s wider information network.

DEFEND3D’s patented technology

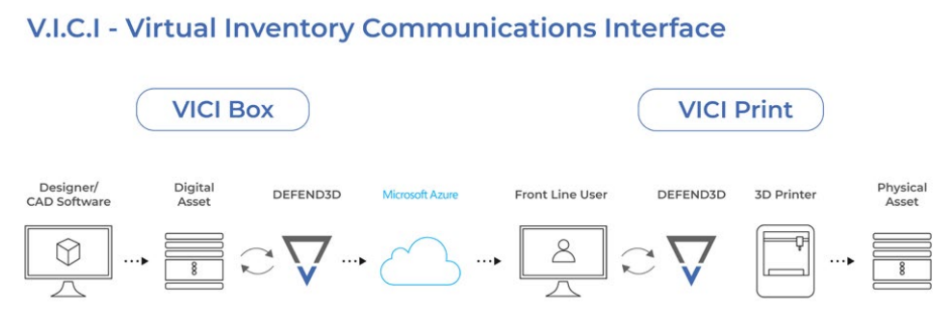

DEFEND3D’s new is designed to securely transmit remote 3D printing, CNC machining, laser cutting, bioprinting, and other digital manufacturing data with its One-Click-Print capability, achieved through its patented security protocol, the Virtual Inventory Communications Interface (VICI).

Removing the need for file transfers, the VICI enables the secure digital resupply of reproduction parts to remote locations through issuing a stream of reproduction instructions that are secured by six levels of security. Through the interface, all manufacturing jobs are recorded to provide an audit trail throughout the entire digital supply chain. Variables such as machine settings and material types can be set in order to ensure manufacturing and quality standards are met.

Essentially, DEFEND3D’s VICI ensures end-to-end encryption to enable organizations to store their designs locally on their home server while allowing them to use their virtual inventory to manufacture parts in remote locations. The company is gearing the technology towards military, aerospace, defense, or energy companies and organizations that wish to protect their IP and prevent cyber attacks, while still being able to deliver 3D printed parts from anywhere in the world.

Testing with the MOD

With the adoption of 3D printing within the defense sector on the increase, the threat of cybersecurity vulnerabilities to IP and process sabotage is a real one. With many military digital assets being too sensitive to be shared externally, the need for a security protocol that doesn’t require owners to send digital print files to external manufacturers has arisen. DEFEND3D’s VICI protocol reportedly achieves this, and could pave the way for defense and industry to work together without compromising on the transfer of sensitive data.

VICI has been tested by the MOD’s UK Strategic Command through the development of a secure digital manufacturing platform that links up a central design hub in a secure facility, with multiple deployed locations that do not have engineering specialists.

The technology has been integrated with Microsoft Azure Cloud in order to enable secure information sharing across services and domains from the MOD’s headquarters to soldiers on the ground at forward-deployed locations. DEFEND3D’s technology was also supported by Azure Remote Rendering to provide artificial intelligence (AI)-based 3D printer remote management and monitoring capabilities.

During testing, the 3D printed products delivered at the deployable end of the DEFEND3D network were compared with those printed at the base location to ensure part quality is maintained. Benchmark tests revealed that printing time and quality were not affected when using the DEFEND3D transmission service, even when compared to the print from an SD card.

An Ultimaker 2+ 3D printer was used to produce the 3D printed test samples, with a standard tensile test piece used for continuity and simplicity printed in three different thicknesses, 3 mm, 5 mm, and 8 mm.

VICI has been designed with a low training burden, meaning that the 3D printer operator does not need to be an expert in 3D printing to be able to print the required files.

“Training to an unskilled user was successful,” said the Head of Mechatronics at the MOD. “Within 30 minutes, they were able to select a file from the catalogue, upload it to the print queue and then follow the instructions to commence a print. This proves the VICI Print software is intuitive and simple to operate minimizing the training burden.”

DEFEND3D vs blockchain

DEFEND3D also believes its new technology could overcome the concerns of blockchain technology, which is another method emerging for securing the digital thread of 3D printing processes, delivered by the likes of SIMBA Chain.

A blockchain is a secure decentralized digital ledger which stores data and records information, known as “blocks”, across multiple computers. The US’ largest 3D printer network using a blockchain technology platform is currently being created as part of Automation Alley’s distributed manufacturing-focused Project DIAMOnD.

According to the company, blockchains can prove inefficient in transporting the data of 3D files due to having ‘proof-of-work’, a measure to combat file manipulation, which slows down the creation of new blocks while the required proof-of-work is calculated and before they can be added to the chain.

By contrast, DEFEND3D’s technology streams 3D printing data directly to the 3D printer in real-time, and only provides information that is necessary at that moment. Additionally, by utilizing blockchain within their 3D printing processes, OEMs typically need to share their IP or digital assets and the entire 3D file still arrives at the printer, potentially leaving it open to interception.

To mitigate this, DEFEND3D’s security protocol prevents file transfer while still providing authentication such as hashing algorithms to ensure the integrity of the data being transferred. The technology also has multiple mechanisms in place to detect any “sniffing” activity or an imminent attack, and will shut down the printing job if such attacks are detected.

Further information on DEFEND3D’s technology to combat cybersecurity risks and IP theft can be found in the recently published whitepaper titled: “Intellectual property & cybersecurity in additive manufacturing within the defense sector”.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows nScrypt’s nRugged FiT system on the back of a truck. Photo via nScrypt.