3D printing marketplace Shapeways has reached a significant milestone in scaling its platform, having 3D printed more than 20 million parts for a diverse range of applications including 3D printed beehives, off-road device mounts, and beer monitoring devices.

Deploying 10 different 3D printing technologies and 90 materials and finishes, Shapeways has been chosen by over a million customers around the world to simplify and speed up their additive manufacturing processes to date.

“Shapeways fosters creative freedom by removing manufacturing guesswork and complexity,” said Miko Levy, Shapeways’ Chief Revenue Officer. “Our purpose-built software, automated manufacturing workflows, and quality processes are accelerating success for some truly groundbreaking products.”

Shapeways’ 3D printing platform

Shapeways offers a range of on-demand additive manufacturing services including EOS’ Selective Laser Sintering (SLS), Stratasys’ full-color, multi-material 3D printing, Carbon’s Digital Light Synthesis (DLS), and Multi-jet fusion technology from HP, enabling a wide variety of products ranging from consumer goods to medical to be produced.

Since recieving $30 million in Series E funding in 2018, the firm has embarked upon further partnerships and collaborations to expand the services of its platform and enable more diverse applications to be fulfilled through 3D printing technologies.

In 2019, the company teamed up with e-commerce website Etsy to give its small businesses a direct channel to manage orders from Shapeways, and soon after partnered with Zverse to integrate its AI-driven CAD as a service platform. Shapeways has since entered into agreements with leading material provider Henkel and global chemical producer BASF to open up access to a greater number of materials and provide more customers with on demand 3D printing services.

A diverse range of applications

Shapeways’ platform has recently facilitated the 3D printing of personal protective equipment (PPE) during the Covid-19 pandemic, alongside 3D printed prosthetics and other medical products. The platform has also been deployed for more obscure applications, such as 3D printed beehives.

Precision pollination firm BeeHero relies on sensors and data science within beehives to assist beekeepers and farmers in ensuring their bees thrive while also optimizing hive productivity. The company developed its BeeHero Smart System using Shapeways’ platform, which sees its sensors housed in two 3D printed nylon cases produced using SLS technology.

The company leveraged Shapeways’ design-for-additive, product development, and digital manufacturing capabilities to produce the sensor housing, which sped up production and delivery time, while improving product quality. The firm claims its real-time pollination monitoring has increased crop yields by an average of up to 30 percent, after the materials used were accepted by the bees.

Shapeways’ 3D printing platform has also been used by premium vehicle mounting solutions firm 67 Designs to develop and manufacture a durable iPad mounting device suitable for off-roading. Working together, the two companies test printed prototypes of potential designs and eventually developed the MagMount G3 device mount, which features a magnet array for iPad alignment and attachment during off-road journeys and is printed in durable yet flexible Nylon 12.

Shapeways’ 3D printing services have been previously deployed within the off-road segment, having helped eco-friendly machine manufacturer Machine Track Technologies (MTT) build a remote control off-road vehicle capable of operating in extreme environments such as deep forests. 3D printing facilitated the rapid prototyping of designs and manufacturing of strong-end-use parts.

Elsewhere, Shapeways was enlisted by Tilt Hydrometer to design and produce a free-floating device capable of monitoring beer gravity and temperature in real-time in order to indicate instant adjustments to the beer fermentation process. By choosing Shapeways for the prototyping and production of the end part, the firm experienced ten-fold cost savings over the plastic milling technology it had previously tried.

The Tilt Hydrometer’s electronics were successfully encased in 3D printed lightweight, flexible and durable plastic in a variety of colours to enable easily-identifiable multiple batch monitoring. Tens of thousands of professional brewery and homebrew customers are currently using the device to aid in creating ideal brewing conditions.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

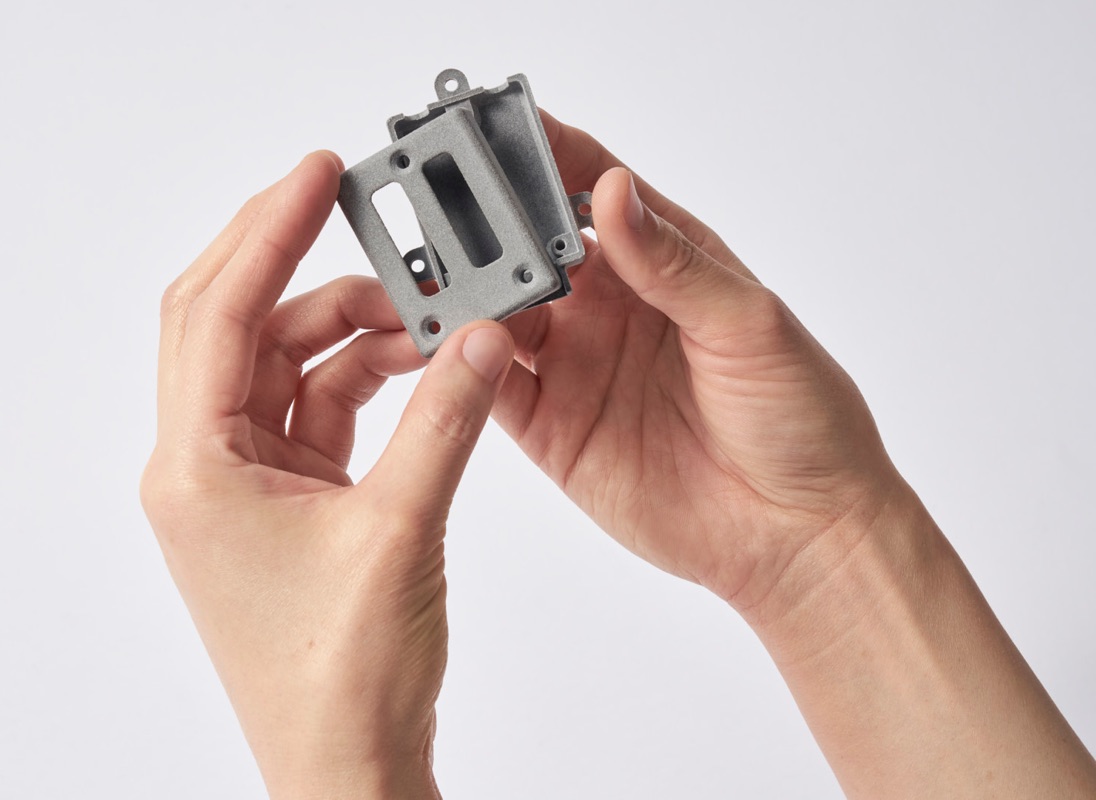

Featured image shows a range of parts that were 3D printed using Shapeways’ existing online platform. Image via Shapeways.