3D printing marketplace Shapeways and global chemical producer BASF have announced a partnership that allows customers to access Forward AM’s materials via a new co-branded website.

Shapeways will use its proprietary technology to introduce clients to Forward AM’s materials, in addition to integrating BASF’s production partners and service bureaus into its order fulfilment process. The online platform will also provide 3D modelling, instant quoting and manufacturing services, aiming to offer quicker and easier access for customers to 3D print functional parts.

“Our partnership with Shapeways and the use of their technology, will allow a broader customer base to create and order high-quality 3D printed prototypes and functional parts online made with our Forward AM material,” said Jim Reddy, Managing Director, North America at BASF 3D Printing Solutions.

“We are focusing on making our high-performance materials easily accessible to consumers while leveraging the manufacturing and services capabilities of our global 3D printing network.”

BASF and Forward AM’s growing materials portfolio

Initially launched as BASF 3D Printing Solutions (B3DPS), Forward AM is BASF’s 3D printing arm, and was set up to expand the company’s additive manufacturing business. In what has been a phase of rapid growth for the subsidiary, its approach has often varied from acquiring other 3D printing companies, to establishing a series of partnerships.

Early on, Forward AM focused on expansion by acquisition, taking over Dutch filament maker Innofil3D in August 2017. As part of the deal, the company’s PLA, PET, ABS and InnoCircle resins were added to BASF’s material portfolio. This was followed by the acquisitions of Solvay’s global polyamide business, and material companies Advanc3D Materials and Setup Performance, which were also merged into BASF’s wider printing business.

More recently, Forward AM has worked with a number of other 3D printing companies to develop new materials, and broaden customer access to its existing range. Collaborating with Silicon Valley start-up Origin for instance, BASF produced a new line of photopolymer resins and used the company’s online platform to expand its service offering. Similarly, Forward AM’s closer relationship with 3D printing service bureau Sculpteo, has also yielded a new collection of 3D printing materials.

Now via a newly-established partnership with Shapeways, BASF is aiming to provide easier access to Forward AM’s 3D printing materials, via the creation of a co-branded online marketplace.

BASF and Shapeways’ co-branded 3D printing website

The collaboration will see Shapeways’ expertise, gained from operating its existing online service bureau, combined with the materials accrued by Forward AM, to offer customers a seamless ordering experience. Forward AM’s existing network of service providers will expedite the process, while Shapeways, having already helped more than one million creators, will handle the customer service element of the business.

“Shapeways’ technology and fulfillment services have been custom-built to fit BASF’s business, and will be able to connect other service providers to supply BASF with a vast network of manufacturers to offer their materials,” said Miko Levy, CRO of Shapeways. “This streamlined process will not only showcase these innovative materials, but will also enable BASF to accelerate its go-to-market strategy in 3D printing.”

In the first phase of the companies’ partnership, the website will carry a range of Forward AM’s Ultrasint powders and Ultracur3D photopolymers. BASF’s Ultrasint PP and HP High Reusability PP for instance, are already available on the platform. While the former is widely-used for the serial production of functional parts, the latter is reportedly versatile, durable, chemically-resistant and ultimately designed for industrial production.

The Ultracur3D RG35 highly-reactive photopolymer meanwhile, which has also been added to the site, offers medium-viscosity and is suited to creating accurate, rigid, multipurpose parts. Finally, Ultrasint TPU01, a high-performing thermoplastic polyurethane which is suited to producing elastomeric functional components, is now available via the website too. Notably, each of these 3D printing materials will allow the platform’s users to produce parts that weren’t previously possible on Shapeway’s existing suite of online services.

Moving forwards, both companies intend to continue working together beyond the website’s launch, with at least five additional new products set to be added to the service before the end of the year. “At Shapeways, it is our goal to empower large-scale additive manufacturing,” concluded Levy. “Our partnership with BASF, enables us to provide the technology to power BASF’s vision in expanding the accessibility of Forward AM materials to more customers.”

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

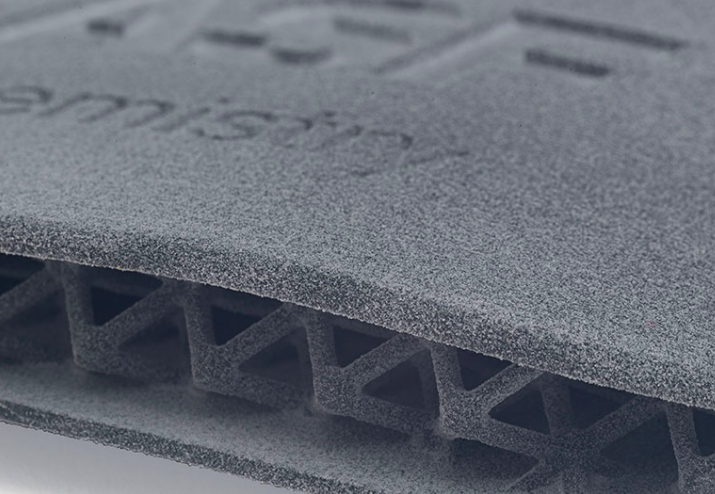

Featured image shows a range of parts that were 3D printed using Shapeways’ existing online platform. Image via Shapeways.