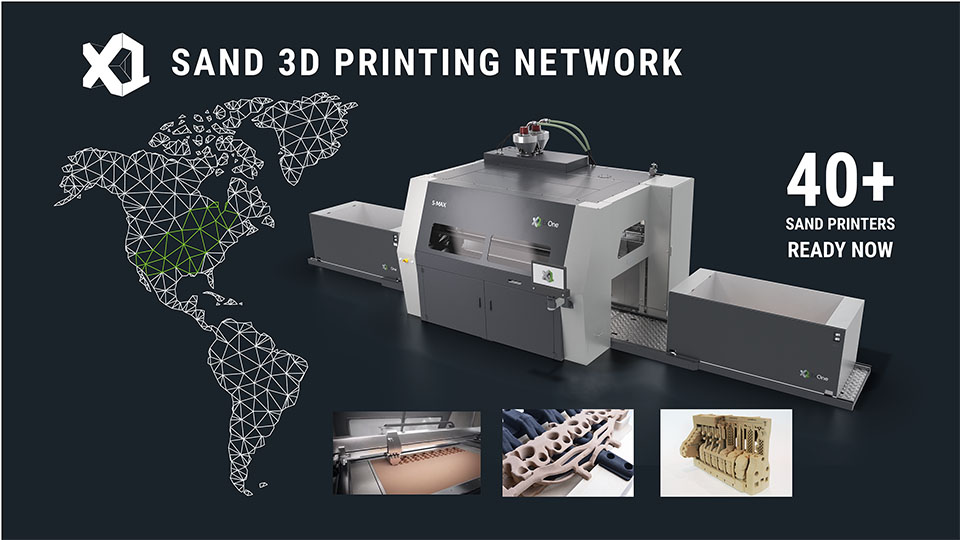

ExOne, the U.S. based specialist in binder jet 3D printing, has launched the Sand 3D Printing Network. The North America network is powered by more than 40 industrial binder jetting systems and will allow customers in aerospace, automotive, agricultural, and other manufacturing sectors to easily access 3D printed molds and cores.

At the core of the Sand 3D Printing Network is a fleet of ExOne’s S-Max and S-Print additive manufacturing systems. The industrial binder jet 3D printers are mainly located at premium pattern shops and foundries throughout the United States, Canada, and Mexico. With the creation of the network, customers can access advanced manufacturing capabilities and benefit from trained operators. Turnaround on orders placed with the network is expected to be 3-5 days.

John Hartner, ExOne CEO said, “The new ExOne Sand 3D Printing Network can help manufacturers easily locate an ExOne sand 3D printer that best meets their needs.”

“What’s more, our network can help ensure a steady supply of sand molds and cores for metal castings, especially during a crisis, as well as enable reshoring of key parts that may be difficult to ship during the ongoing COVID-19 pandemic.”

High-quality 3D sand molds and cores

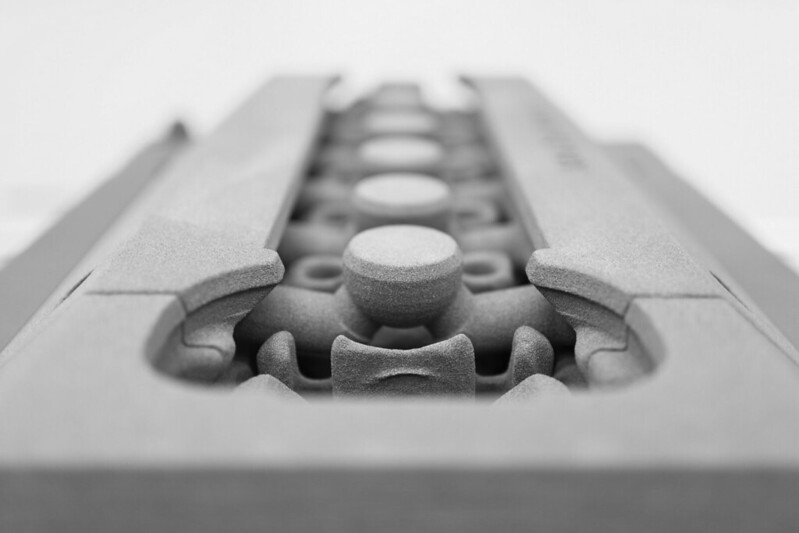

3D printed sand molds and cores enable the production of high-value metal casting projects and can confer numerous advantages. ExOne highlights the fact that binder jet 3D printing allows sand cores to be produced as a monolithic unit. Therefore labor, error and scrap costs are removed in comparison to the alternative method of assembling multiple cores prior to casting.

Furthermore, manufacturers are freed from traditional design constraints when using 3D printing. This means not only are new designs possible but also the iteration process of refining a design is much swifter.

A specific advantage conferred by using additive manufacturing in the foundry workflow are the 3D-enabled rigging, riser, and gating designs that simulate the casting process, thus enabling high-quality castings that are frequently completed in a single pour.

Another benefit of the digital-based process is that the design files for 3D printed molds and cores are simple to store. Unlike traditional methods, there is no requirement for the costly creation, storage or repair of patterns or molds for later reuse.

For manufacturers seeking to access these advantages, ExOne’s OneCast support service can provide in-depth expert know-how and design assistance.

The Sand 3D Printing Network and ExOne binder jet 3D printers can be used with many foundry materials including aluminum, bronze, copper, nickel-based alloys, iron, magnesium, steels, titanium, and zinc.

To locate an ExOne sand 3D printer in the network for your project, visit the link.