Metal 3D printing specialist 3DEO has been awarded a win at the 2020 Design Excellence Award Competition for its metal 3D printed production part. The steel part, an anchor link, marks the company’s efforts in pushing forward a new technology and design with commercial success.

The competition, sponsored by the International Trade Association for Metal Powder Industries (MPIF), invites metal powder part fabricators to submit components they have manufactured throughout the year. It is split up into three major technology categories (metal additive manufacturing being one of them) and judges submissions based on their ability to showcase the advantages of powder metallurgy.

Dr. Payman Torabi, 3DEO’s co-founder and CTO, states: “We are honored to receive this award of distinction from MPIF. It is a terrific accomplishment for 3DEO that highlights the giant leaps we have made over the last 18 months commercializing our technology.”

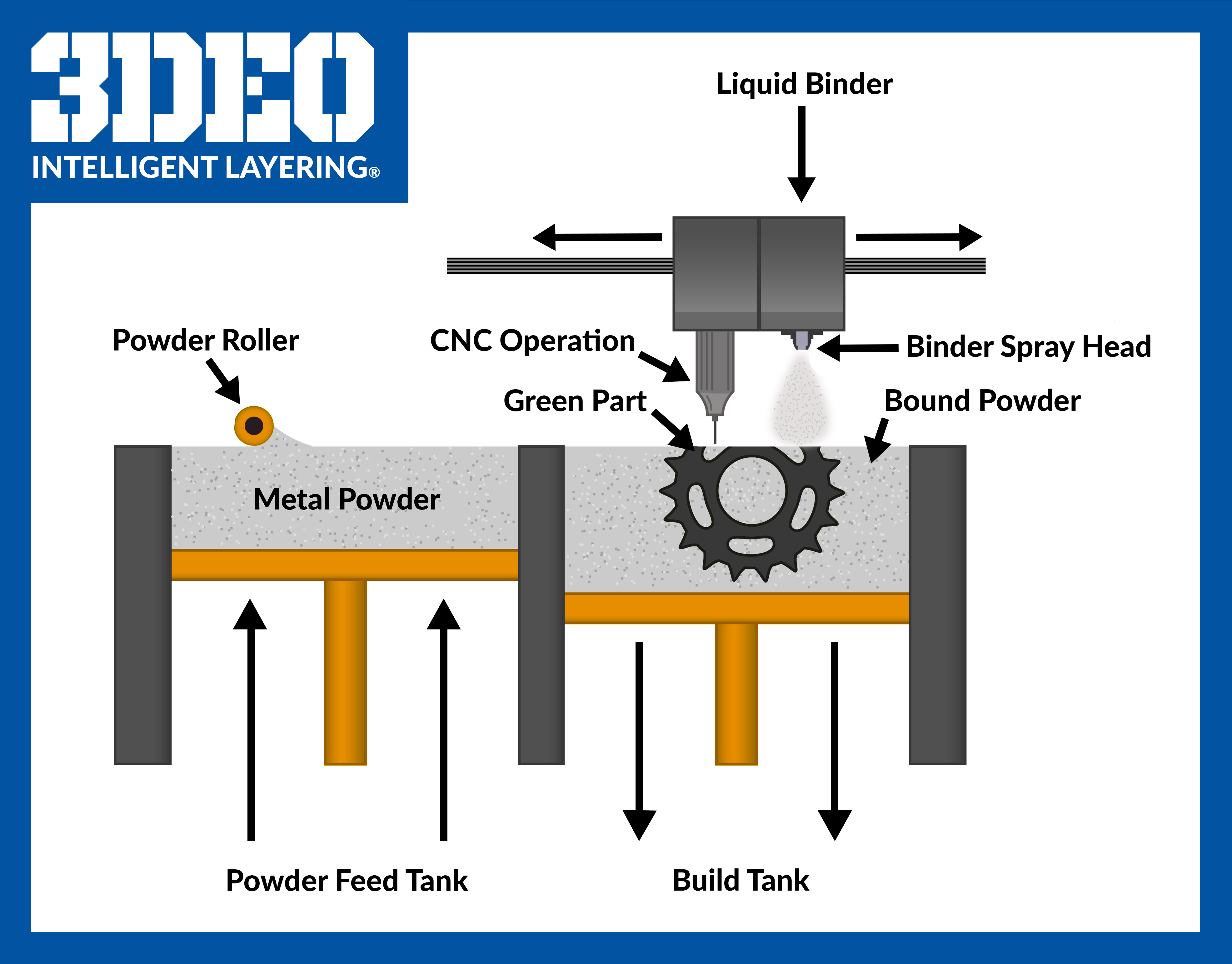

Intelligent Layering

3DEO has its own proprietary metal 3D printing technology called Intelligent Layering. Interestingly, the company doesn’t actually sell its printers, instead opting to provide a 3D printing service for anyone interested. 3DEO claims its unorthodox business decision is intended to “reduce the burden of getting started” while lowering the final part cost for its customers.

Intelligent Layering is a binder jetting-based 3D printing technology, whereby a liquid binding agent is selectively sprayed onto a bed of metal powder, fusing the individual granules into solid layers. 3DEO’s machines also have an additional subtractive toolhead that mills the printed parts into the desired final shape if need be. The company focuses on 17-4PH stainless steel but advertises other material possibilities such as copper and titanium.

Torabi adds: “3D printing is an incredible modern tool with a lot of advantages. You can’t utilize all its potential powers with an outdated mindset or approach. We as engineers, designers, builders, and innovators need to start rethinking our methods so all of humanity can witness and benefit from a new industrial revolution.”

Toppling the CNC throne

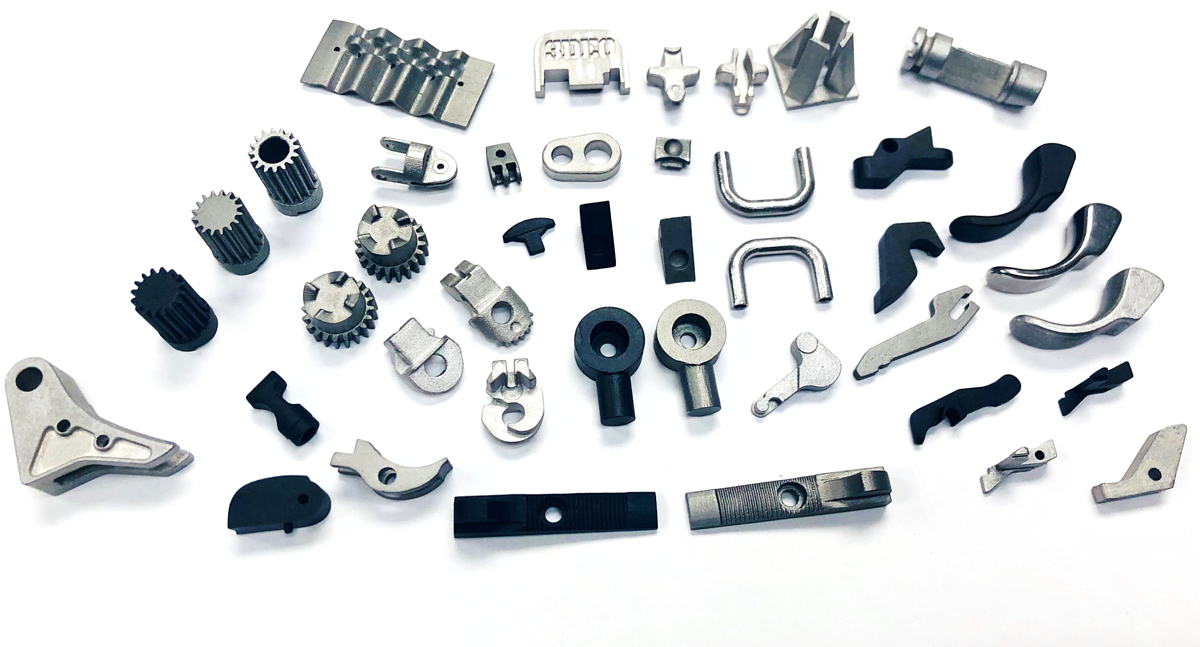

3DEO prides itself on its low prices and high part volume potential. Its technology aims to be a direct competitor to traditional manufacturing in terms of part pricing, material properties, and throughput. In fact, its 3D printed anchor link had to triumph over a number of other metal powder parts produced via conventional powder metallurgy and metal injection molding.

Dr. Matt Petros, 3DEO’s CEO, concludes: “It is particularly exciting to me that the winning component is a high-volume production part, not a one-off prototype. We had to out-compete CNC machining to win the production order, and we did that with a lower piece price AND the ability to seamlessly scale quantities into very high volumes. It was a ‘win-win’ for both 3DEO and our customer.”

Earlier this year, 3DEO significantly ramped up its production, passing the 150,000 end-use part milestone. The achievement was an important one for the on-demand additive manufacturer, as it cemented the company’s market presence against the more conventional manufacturing techniques it now competes with.

Around the same time, 3DEO also announced a triple digit annual growth in its business metrics for 2019. Approximately 40% of its customers were in the defense industry, 35% were in medical, and 25% were in aerospace.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed anchor link. Photo via 3DEO.