3DEO, the Californian developer of Intelligent Layering metal 3D printing technology, has announced a triple digit annual growth in its business metrics for 2019.

The company’s success, 3DEO explains in a press release, comes after it adopted a vertically integrated, “solutions oriented” business model in order to compete with high-volume traditional manufacturing. “We are very proud of the growth that was accomplished over the last year,” comments Matt Sand, 3DEO President. “It is clear that 2020 will be another record-setting year for 3DEO as our pace of adoption across all industries is accelerating. More than a metal 3D printing company, 3DEO is a solutions provider helping our customers tackle their most challenging manufacturing problems.”

With this new business model, manufacturers looking for metal parts are able to use 3DEO’s service to leverage the benefits of the company’s 3D printing technology, without having to spend large amounts of money on an internal 3D printer with the supporting infrastructure.

“What’s more,” Sand adds, “almost every customer we are working with is using metal 3D printing in production for the first time. We are in the trenches with our customers, and our growth curve is a testament to the demand for these solutions.”

“In the end, our mission is to do for manufacturing what Amazon’s AWS did for the internet by offering low-cost access to flexible, scalable, and world-class manufacturing infrastructure.”

Intelligent Layering 3D printing technology

Founded in 2016, 3DEO is an on demand manufacturer of stainless steel parts. The company leverages its proprietary Intelligent Layering technology to 3D print the metal components and provide them to its customers in the medical, defense, aerospace, and other industrial markets.

According to 3DEO, Intelligent Layering Technology enables the production of metal components with excellent surface quality, low cost structure and fine features. This patented process is integrated into 3DEO’s own 3D printers and uses Metal Injection Molding (MIM) powders to reduce the final part cost, while also enabling high volume metal additive manufacturing. Intelleting Layering technology also meets the industry benchmark MPIF Standard 35, the standard for Metal Injection Molding.

In 2018, the company 3D printed over 30,000 paid parts using its proprietary process, distributing them to customers across various industries, including medical, aerospace and consumer. Then in Q1 2019, 3DEO announced it was doubling its Intelligent Layering production capacity after securing two more production customers, comprising 24,000 pieces and 28,000 pieces each.

At the time of the expansion, 3DEO explained that it was in response to greater customer demand, with the company experiencing significant growth in 2018, its second full year of operation.

Growth in 2019

Continuing its annual growth, 3DEO’s new business model has enabled a 600 percent increase in revenue for 2019 over 2018. This coincides with a 394 percent increase in the number of parts shipped in 2019 over 2018 as well. Approximately 40 percent of those parts were customers in the defense industry, whereas 35 percent were for medical and 25 percent for aerospace.

Additionally, the company has expanded its workforce by 172 percent – 3DEO now has 60 employees compared to 22 in 2018. Its vertically integrated business model has led to a number of new jobs in different areas, with the most noteworthy employee increase coming in the R&D department.

Finally, 3DEO has also increased the number of its Intelligent Layering production 3D printers at its facility in California by 566 percent. “We’re doing things in manufacturing that previously couldn’t be done,” comments Matt Petros, 3DEO’s CEO. “And we’re doing it by leveraging several enabling technologies that are converging right now in manufacturing – in a way that finally allows metal 3D printing to shift the serial production paradigm.”

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

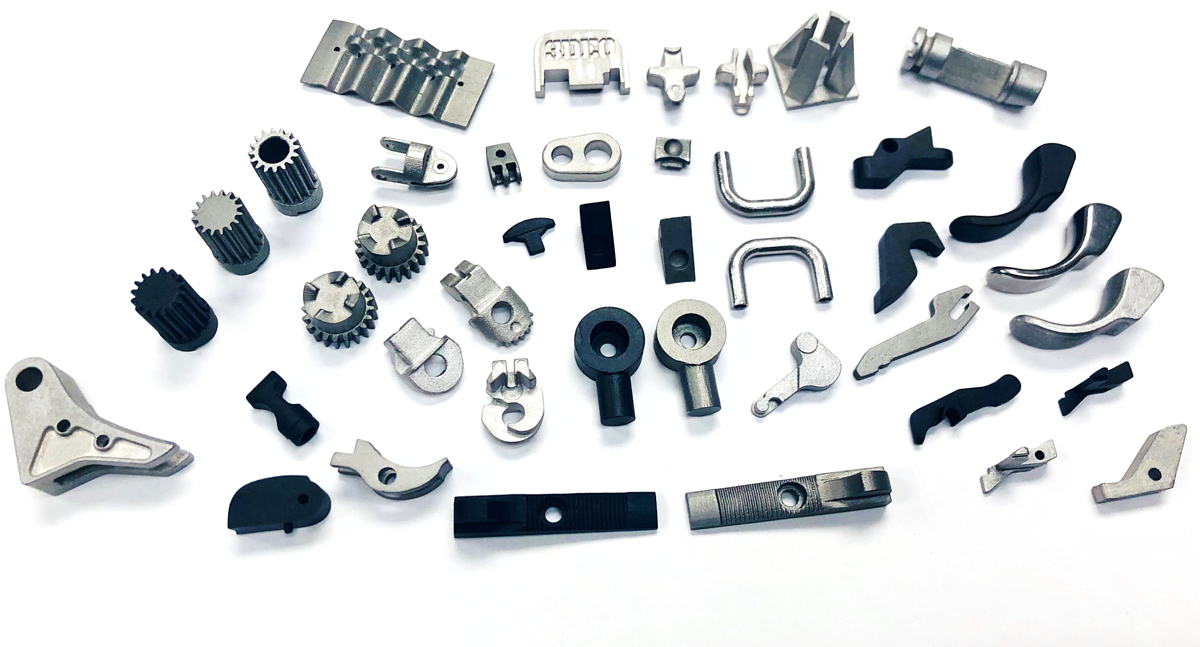

Featured image shows collection of small metal parts 3D printed by 3DEO. Photo via 3DEO.