3D Systems has announced its financial results for the first quarter 2020.

Total revenue for the company during Q1 2020 was reported at $134.7 million, an 11.4 percent decline compared to $152.0 million in the same period last year. The fall in revenue has been attributed to the COVID-19 pandemic, which has had a negative impact on the results across 3D Systems’ different business segments.

However, to combat the economic impact of the pandemic, Vyomesh Joshi, president and CEO at 3D Systems, explains that the company has reduced its expenses and preserved cash: “COVID-19 has presented unprecedented challenges globally, so we asked our customers and partners to help address these challenges with 3D printing. Over the last several weeks we have seen applications of our technology and software being used to assist COVID-19 efforts, from ventilator parts to personal protection equipment to nasal swabs,” comments Joshi.

“Amid this uncertain environment we have managed the company by continuing to reduce expenses and preserving cash, and we believe we will be well-positioned when the market comes back.”

In the earnings call with investors and analysts, Joshi goes into further detail about the impact of COVID-19 and the response of 3D Systems, as well as the ways in which the company is supporting the frontline battle against the pandemic.

3D Systems revenue for Q1 2020

3D Systems revenue is reported across two divisions: Products and Services. The former accounts for the company’s revenue generated by 3D printers, software and materials. Services include the revenue from 3D Systems’ healthcare solutions and the company’s general on-demand manufacturing capabilities.

In Q1 2020, Products revenue was reported at $78.8 million, a decline of 13.5 percent compared to the figure for Q1 2019, which was $92.3 million. Experiencing less of a decline compared to the Products segment, 3D Systems’ Services revenue in Q1 2020 fell by 6.3 percent to $55.9 million, from $59.6 million during the same period last year.

| Revenues | Q1 2020 | Q1 2019 | Variance $ millions | % |

| Products | 78,809 | 92,347 | -13,538 | -14.66% |

| Services | 55,896 | 59,633 | -3,737 | -6.27% |

| Total Revenue | 134,705 | 151,980 | -17,275 | -11.37% |

In the Products division, 3D printer revenue decreased by 35.5 percent for Q1 2020, whereas Materials revenue decreased by 0.1 percent. Software revenue also fell by 7.7 percent in Q1 2020, compared to the same period last year.

Within the 3D systems Services segment, healthcare solutions revenue decreased 7.3 percent in Q1 2020. Additionally, on demand services revenue declined by 12.8 percent.

Impact of COVID-19

Discussing the significant decline in 3D printer revenue during the earnings call, Joshi explains that it was impacted by the effects of the COVID-19 pandemic on end user demand across aerospace, automotive and healthcare. Joshi also highlights the dental and jewelry industries, key markets for 3D Systems’ SLA 3D printers: “When you think about the SLA printers, the printers for dental, we talked about the dental market being slow. The jewelry market also, because that’s a category which is not going to be really consuming a lot of materials, because that’s an item people will not be really buying in the current very tough environment.” In the first quarter of 2020, 3D Systems launched a package for its Figure 4 3D printing platform specifically for the 3D printed jewelry market, including hardware, software and materials.

As manufacturing activity in general has been impacted negatively, Joshi suggests that new software licenses had a tough quarter. In the earnings call, Joshi highlights the slowdown in the automotive market as having a particularly strong impact on 3D Systems’ Cimatron software for mold, die and tool makers.

As such, Joshi comments that 3D Systems is currently working on optimizing its cost structure to combat the economic impact of the pandemic: “As we start seeing COVID impact, we [will] focus even more on cost structure. Amid the pandemic, our executives and board members [took a] 10% pay cut, and the majority of the employees are taking limited furloughs. We pushed out some R&D programs and have reduced hiring significantly.”

A key topic of the call focused on the benefits of additive manufacturing amid the ongoing disruptions in global supply chains, where it has been used to help manufacture PPE equipment and basic supplies for healthcare environments. Outlining 3D Systems’ response to the pandemic, Joshi states: “Over the last several weeks, we have seen applications of our technology and software being used to assist COVID-19 efforts. Due to the shortage of personal protection equipment, our employees wanted to focus on a high impact area […] We designed and developed our own high-efficiency face shields frame over the course of 2 days, and our printers can output 100 face shields every 24 hours.” Additionally, 3D Systems’ 3D printers were also used to produce ventilator valves and nasal swabs.

Looking ahead, it is unclear to determine the long-term impact of COVID-19, but Joshi explains that 3D Systems’ near-term results will continue to be affected. As such, the current focus for the company is on cash generation and optimizing cost.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

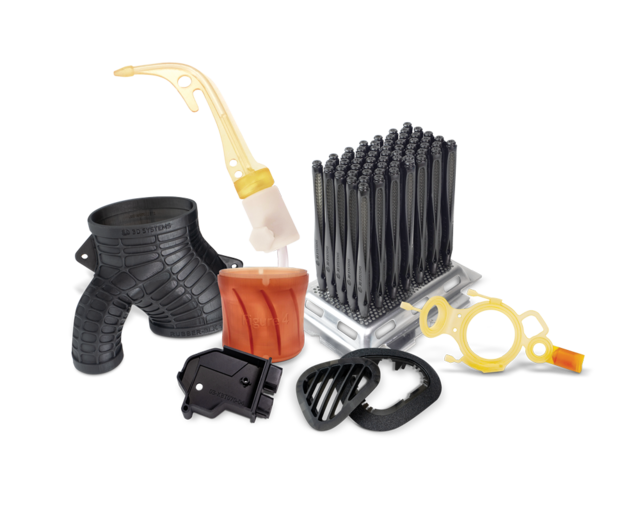

Featured image shows parts made of Figure 4 materials. Image via 3D Systems.