3DEO, the Californian developer of Intelligent Layering metal 3D printing technology, is tackling the barriers of metal additive manufacturing in its first live webinar on March 28th.

Matthew Petros, 3DEO CEO, will host the educational webinar “Metal 3D Printing Made Easy from Prototyping to Production” at 11 am (PST) to provide insight on how the company’s proprietary technology is accelerating industrial additive manufacturing.

Register for the upcoming webinar here, which is the first in a monthly series covering industry case studies, metal 3D printing technologies, and designing for metal additive manufacturing.

“The journey of moving metal AM parts from prototyping into high-volume production can be incredibly challenging. In this webinar, we’ll show you how 3DEO breaks down the barriers to production in metal additive manufacturing. We’ll shine a light on the barriers to production and how you can get there with 3DEO,” said Petros, CEO at 3DEO.

“The first webinar in our series is designed to help you understand the true technical and economic challenges associated with metal AM. We will show you how to get started immediately with metal AM and avoid common pitfalls.”

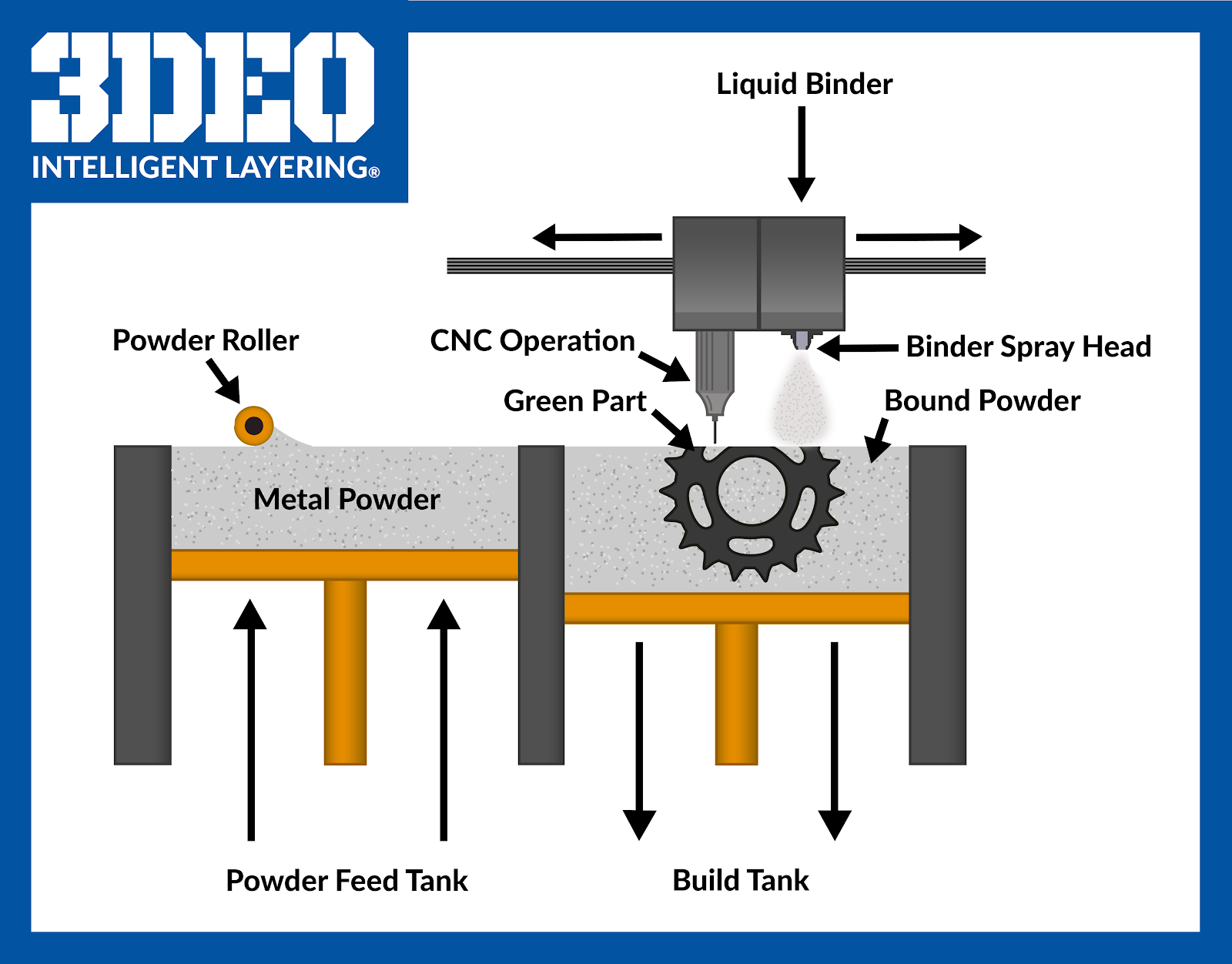

Intelligent Layering technology

3DEO developed Intelligent Layering for high volume metal additive manufacturing. This technology, which is integrated into 3DEO’s own 3D printers, uses Metal Injection Molding (MIM) powders to bring a significant cost saving on parts as well as an open an industrial material palette. Petros previously told 3D Printing Industry that 3DEO is manufacturing in stainless steel 17-4PH with engineering level tolerances and part densities of 99.5%.

The company’s aim “to realize the benefits of moldless manufacturing” has enabled the production of tens of thousands of metal 3D printed parts that exceed the standard for MIM, i.e., MPIF Standard 35.

The webinar will help attendees understand how 3DEO’s technology can be used to move parts from prototyping to production as well as post-processing. It will be followed by a live Q&A session.

“Printing the part is only the first step,” added Petros. “Post-processing can comprise as much as 50% of the total cost of the part. Understanding what’s required in post-processing (and all other costs) are critical to developing winning metal AM applications.”

Reserve your free place for the Metal 3D Printing Made Easy from Prototyping to Production webinar now.

For more of the latest news on 3DEO and 3D printing subscribe to the 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook.

Also, visit 3D Printing Jobs for new opportunities in your area.

Featured image shows the 3DEO webinar image. Image via 3DEO.