Michigan-based additive manufacturing services provider Qualified3D and German additive manufacturing service provider MetShape have assisted students from International Space Station (ISS) Lab at San Jose-based Valley Christian High School with a microgravity experiment.

The team required millimeter-scale lattices for capillary action trials in microgravity. Consequently, they contacted Qualified3D to obtain components manufactured using micro-stereolithography. Emeka Okekeocha, ISS Program Manager at Valley Christian School said, “Some of our students discovered that the miniature lattice design was printable using the LMM technology and proactively reached out to them.”

“We are very thankful to Qualified3D for how they always quickly responded to our requests and questions. Even with the many changes we requested, the parts were still delivered on time, which helped us to transition smoothly between planning and building our microgravity experiment,” said David Kou, an 11th-grade member of the team at Valley Christian School.

How were the students able to find the solution for this microgravity experiment?

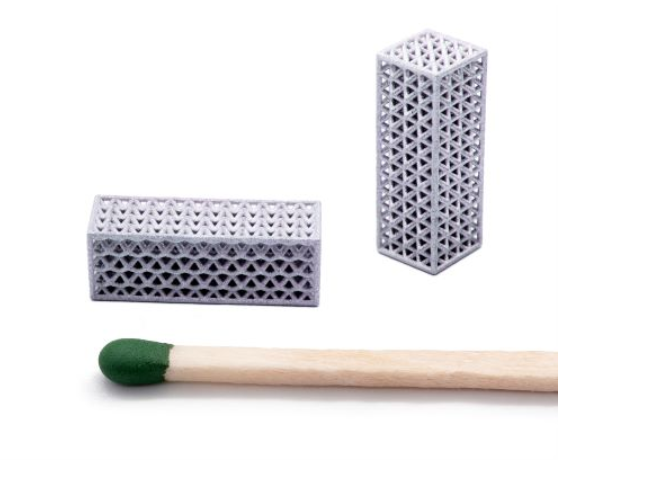

The San Jose-based team’s lattices consisted of struts as thin as 0.5mm in diameter, and micro-SLA appeared to be the only process capable of producing parts with adequate precision. Although dimensionally precise, photopolymer resin components were not a suitable match for space flight needs because they lacked vibration resistance, heat, and low temperatures. Metal offered a superior set of characteristics for the ISS experiment. However, the lattice design was not printable utilizing standard metal powder-bed fusion and binder-jetting 3D printing technologies.

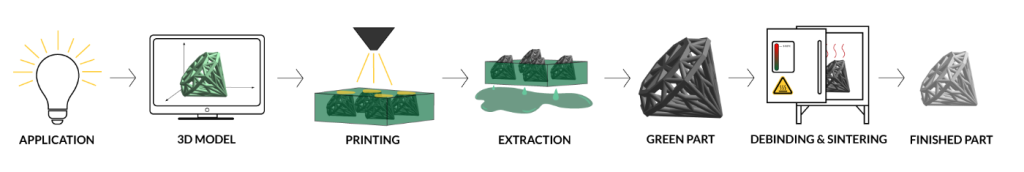

As a result, the group decided to use MetShape’s Lithography-based Metal Manufacturing (LMM), a novel 3D printing technique that employs the photopolymerization principle, wherein the metal powder is distributed in a photosensitive resin and carefully polymerized by a DLP projector. In a wide range of metals, which include titanium and stainless steel, the technology can create components with smooth surfaces (2-5µm surface roughness before polishing) and ultra-thin walls (125µm). Okekeocha further stated, After a technical review, we accepted the proposed change from acrylate resin to stainless steel.”

The ISS Research Lab students obtained their components within a couple of weeks and are excited to employ them in their microgravity experiment. The experiment package is expected to be delivered to the ISS in mid-February 2023 and to initiate returning data in March 2023.

Furthermore, Metshape is globally known for its know-how in 3D printing and sintering LMM micro parts. It also retails its services to clients in the United States via Qualified3D.

Additive manufacturing playing a vital role in microgravity advancements

Previously, AddUp, a French industrial 3D printer manufacturer, announced that a novel machine it helped design would be launched into orbit for evaluation onboard the ISS. AddUp built the inner structure and mechanisms of a machine specially designed to 3D print metal parts in space as part of the European Space Agency‘s (ESA) ‘Metal3D’ project. The prototype, unlike traditional powder bed-based systems, is claimed to process wire feedstock attached to its frame, preventing it from floating away and enabling the device to operate in microgravity conditions.

Furthermore, Swedish 3D bioprinter manufacturer CELLINK announced a strategic partnership with Made In Space, a microgravity manufacturing specialist. The collaboration’s objective was to determine 3D bioprinting development opportunities for the ISS and future off-world platforms. Such initiatives are expected to have a real-world impact on drug screening and cancer research on Earth, claims the company.

“CELLINK supports space programs in the United States with our deep commitment to cutting-edge innovation, extensive portfolio of technologies, and a world-class team of scientists and engineers,” said Erik Gatenholm, co-founder and CEO of CELLINK.

Follow this link for all the 3D Printing Trends 2023.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows 3D printed metal lattices manufactured by MetShape. Image via MetShape.