Cranfield University in Bedford, UK, has just received official approval to launch a new Master’s Degree in Metal Additive Manufacturing. Now accepting applications for October 2019 intake, this MSc will give students direct access to the university’s state-of-the-art Wire + Arc Additive Manufacturing (WAAM) systems, and the chance to work on projects for the WAAMMat consortium of 20 industrial partners.

Industry-integrated additive manufacturing study

The Metal Additive Manufacturing MSc at Cranfield will be taught by a leading team of industry-active academics, including Dr. Filomeno Martina, Senior lecturer in Additive Manufacturing and manager of the WAAMMat research program. Working closely with industry collaborators such as BAE Systems, Airbus and Lockheed Martin, the purpose of WAAMMat is to increase the maturity of WAAM technology.

Speaking earlier in the year about general research objectives for 2019, Dr. Martina said, “[…] we will continue developing new methods to achieve better-than-forged properties, […] We are also working on a physics-based qualification framework which will avoid the expensive configuration-control approach (in which you lock feedstock, machine and parameters) which is otherwise adopted today.”

“With our novel method, it should be possible to achieve qualification much more quickly and inexpensively, at great benefit of industrial pick-up.”

Other Cranfield academics teaching on the degree include Dr. Sue Impey, Dr. Supriyo Ganguly, Dr. Paul Colegrove, Dr. David Ayre and Dr. Wojciech Suder. Clients of these faculty members include leading Honeywell, Rolls-Royce and Tata Steel.

Modules and assessment

The Metal Additive Manufacturing MSc is taught across nine compulsory modules:

– Additive Manufacturing System Design

– Finite Element Analysis

– General Management

– Management of Manufacturing Quality

– Metal Additive Manufacturing Processes

– Metal Additive Manufacturing Metallurgy

– Net-shape Manufacturing and,

-Post-processing for AM

Assessments for each of these modules will account for 40% of a student’s overall grade, with a Group project/dissertation accounting for 20%, and the Individual project a further 40%.

A demonstrable impact on large-scale AM

Throughout this degree, students will be given hands on experience of topics such as process monitoring, porosity problem solving and new materials processing. A potential extension of this work, done in a group, the individual project allows students to focus on a particular area, such as material property characterization.

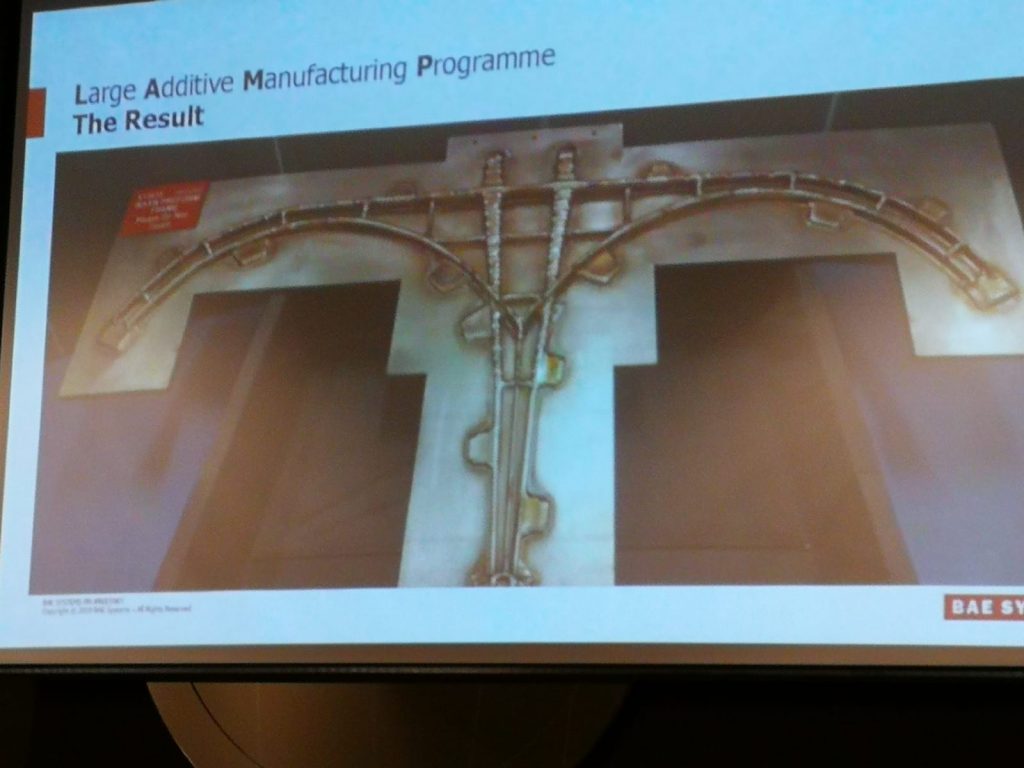

Recently the Cranfield University’s WAAM department and spinout company WAAM3D unveiled details of two of their most high profile projects to date. For Franco-Italian aerospace manufacturer Thales Alenia Space, the collaborative produced a large-scale prototype pressure vessel. And, working with BAE Systems, they created a 2.5m x 1.5m rear frame for the Eurofighter Typhoon using WAAM technology.

If that isn’t enough to consider the degree however, Dr. Martina adds, “Cranfield has been developing AM technologies for over a decade and has always been informed by industry and its needs. We have acknowledged a massive skill gap in the field of AM, […] There is no industrial success without the right people and skills.”

“We have shaped this course based on what industry needs in practice, what we think is key in terms of scientific theory, and what the graduate students want to have a fun year on our campus.”

“Building on our extensive industrial network, research, teaching and practical projects will meet to give prospective students the necessary toolbox to make them AM champions once they complete the course. We can’t wait to get started!”

More information about the Cranfield University Metal Additive Manufacturing MSc can be found here.

Cranfield University and BAE Systems has been nominated for Innovation of the Year in the 2019 3D Printing Industry Awards. Vote now to decide this years winners.

For all of the latest additive manufacturing business news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking the next step in your career? Visit 3D Printing Jobs for current vacancies in this rapidly growing sector.

Featured image shows a large-scale WAAM-made component. Photo via WAAM3D