Award winning on demand manufacturing provider Protolabs and Colorado-based additive manufacturing consultants Wohlers Associates have collaborated to run a Designing for Additive Manufacturing (DfAM) course. Taking place over three days, the course is an invitation-only event, established through a shared desire between the companies to help engineers and designers effectively use 3D printing technologies. Most of the course will take place near Raleigh, North Carolina, with the programme concluding at Protolabs’ 77,000 sq. ft 3D printing facility in Morrisville.

“Additive manufacturing has moved well beyond this worn-out notion that it has to prove its worth— we’ve seen first hand its maturation over the years and have literally 3D printed millions of parts during that time,” explains Protolabs’ President and CEO, Vicki Holt. “We know it’s an extremely valuable prototyping tool but it has now made significant strides in materials and technology where production is its logical next phase.”

“Collaborating with the world’s leading additive experts—and those who look to leverage that technology to its fullest—will serve to proliferate the education and adoption of 3D printing.”

Helping companies realize the full potential of additive manufacturing

Terry Wohlers, Principle Consultant and President at Wohlers Associates, will be leading the course alongside Olaf Diegel, Associate Consultant at Wohlers Associates, where both will hold a discussion about DfAM. Diegel also operates as head of the Creative Design and Additive Manufacturing Lab at the University of Auckland, and will bring his knowledge and experience from this position to the DfAM course. Several polymer and metal 3D printing engineer experts from Protolabs will also be joining Wohlers and Diegel in leading the course.

“Designing for AM offers unique challenges and opportunities not found in traditional design methods,” commented Terry Wohlers.

“Protolabs brings tremendous depth of expertise and leadership in 3D printing. We’re thrilled to work together to equip attendees with technical skills and manufacturing knowledge needed to unlock the full potential of additive manufacturing.”

Protolabs advancing industrial 3D printing

For Protolabs, the DfAM course is part of a larger objective to advance additive manufacturing as a credible and effective option for the manufacturing industry. The partnership with Wohlers Associates follows previous initiatives to push this goal forward. In 2018, the company joined GE Additive’s Manufacturing Partner Network (MPN), which aims to overcome hurdles in the 3D printing industry, specifically helping customers additively manufacture components at a higher volume.

Furthermore, Protolabs also became a founding member of Massachusetts Institute of Technology (MIT)’s Center for Additive and Digital Advanced Production Technologies (ADAPT) consortium, which focuses on scaling new manufacturing technology through research, and accelerating the implementation of additive manufacturing.

Demonstrate your design skills and a win an Ultimaker 3. Protolabs is sponsoring the 2019 3D Printing Industry Awards trophy design competition. Enter your design now.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

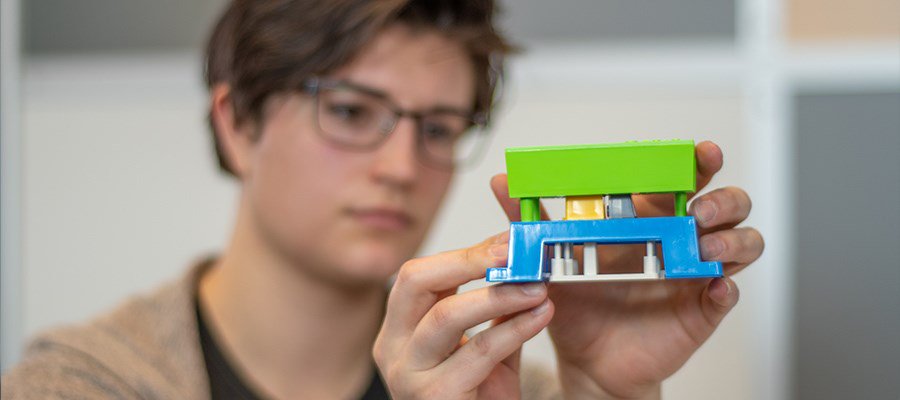

Featured image shows Protolabs educational design aid in use. Photo via Protolabs.