In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across our industry.

Today’s edition features supply chain updates, additive manufacturing partnerships, new 3D printing materials, a number of investments in the industry and a 3D printed off-road electric vehicle.

Read on for the most recent updates from 3D Printz, RIZE, Bondtech, Slice Engineering, 3DPRINTUK and more.

3D printing partnerships for 3D Printz, Lulzbot, Cincinnati Inc.

Starting with the latest collaborations, UK-based 3D printing company 3D Printz has signed a distribution agreement with extruder developer Bondtech. The Swedish company develops and manufactures dual drive extruders that grip and push the filament from both sides during printing for a secure and stable feed. Following the agreement between the companies, 3D Printz will become part of Bondtech’s network of distributors and resellers which now spans 50 countries.

“We’re delighted to become one of just a handful of UK companies to offer Bondtech products,” said Peter Roberts, Director of 3D Printz. “We’ve taken great strides over the past few months to widen our offering, as part of our desire to provide a one-stop-shop for all 3D printing needs.”

Machine tool manufacturer Cincinnati Inc. (CI) has formed a mutually beneficial distribution partnership with custom CNC machine designer Multiax America. As part of the deal, Multiax America will offer CI’s Big Area Additive Manufacturing (BAAM) machine, and CI in turn will supply the Multiax line of 5-axis routers. The resulting turnkey solution provides both companies’ customers with a more comprehensive service from 3D printing right through to optimizing a part’s surface finish.

“Because an overwhelming majority of BAAM-printed parts require secondary machining, we’ve had a goal to partner with a leading CNC machine manufacturer for some time,” said Alex Riestenberg, Additive Manufacturing Product Manager at CI. “Multiax is that manufacturer. Our open-book relationship will make both of us stronger, and it will ultimately better serve the customer.”

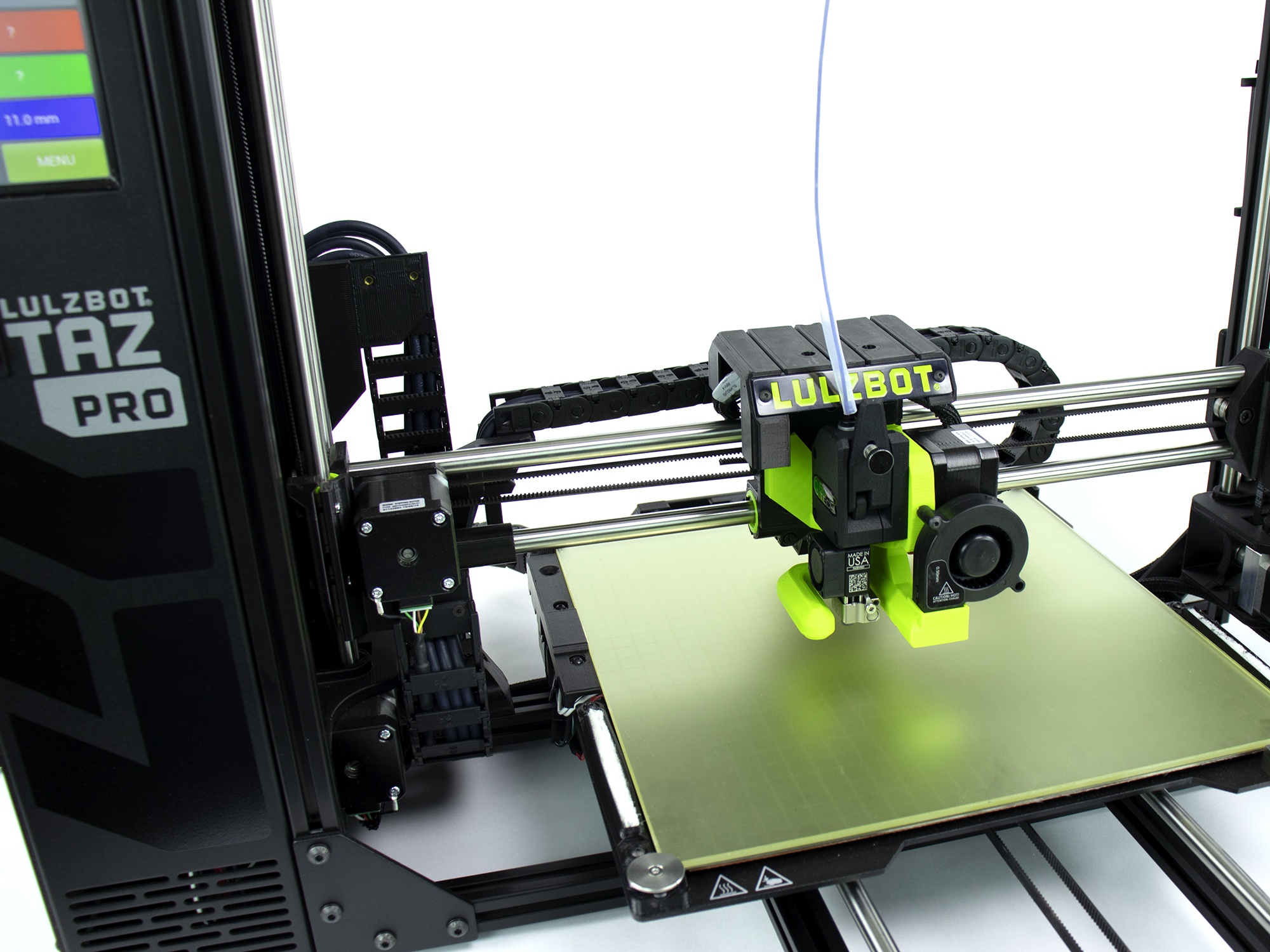

3D printing part provider Slice Engineering has announced an agreement with 3D printer manufacturer LulzBot to provide key components for its new M175 tool head. The device, consisting of a Mosquito Hotend and new Bridgemaster nozzles from Slice Engineering, enables LulzBot customers to print with 1.75 mm filament for the first time.

Like all Lulzbot systems, the M175 has been designed with a Universal Tool Head System, making it a ‘drop in’ upgrade for the Mini 2, TAZ Workhorse and TAZ Pro printers. Owners of the LulzBot Mini 1, TAZ 5 and TAZ 6 can make the M175 tool head compatible with their system by adding the Universal Tool Head Adapter, sold separately by LulzBot.

“Slice Engineering has impressed the world with their attention to detail and commitment to quality,” said John Olhoft, President of LulzBot. “These same traits will mesh well with the Reliability, Repeatability, and Performance that can be expected from each and every LulzBot product.”

Certifications and awards for RIZE and Protolabs

Boston-based 3D printer manufacturer RIZE has announced that its RIZIUM ST fibers, inks and XRIZE full-color, composite 3D printer have gained UL GREENGUARD certification. The accreditation is awarded to companies that ensure their materials and devices are safe from toxic airborne emissions emitted during production. RIZE is the only 3D printing firm so far to have earned full GREENGUARD compliance for its materials, inks and full-color systems.

According to a study carried out by research group Chemical Insights, harmful emissions are compromising the indoor air quality around people that work near 3D printers. A standard method of testing 3D printer emissions has been introduced in response to the report called ANSI/CAN/UL 2904. GREENGUARD certifies that additive manufacturing companies have met these stringent pollution and chemical measures, and issues certification on this basis.

“GREENGUARD Certification is the gold standard for 3D printing health and safety,” said Andy Kalambi, CEO of RIZE. “We’re delighted that RIZE’s materials-first approach to 3D printing is getting recognized by scientific leaders as well as major manufacturers.

On demand digital manufacturing provider Protolabs, has received the RoSPA Gold Award for keeping its staff, customers, contractors and any visitors to its facility in Shropshire safe. The RoSPA scheme is the longest running of its kind in the UK, and receives entries from organisations around the world. Although many of the program’s awards are non-competitive, around seven million people are currently impacted by the health and safety project.

“We are delighted to have won a RoSPA Gold Health & Safety Award and it is testament to the magnificent work of the whole team here,” said Lee Ball, General Manager of Protolabs’ Telford facility. “Great pride is taken in achieving excellence in the workplace, whether that is being at the forefront of innovation or creating the safest possible working environment for our employees.”

MTT builds vehicle using Shapeways 3D printing technology

Eco-friendly machine manufacturer Machine Track Technologies (MTT) has used the services of 3D printing bureau Shapeways to build its MTT-154 remote control track vehicle. The machine has been created to operate in extreme conditions such as deep forests, either extracting injured people or taking those there that can’t walk. 3D printing was utilized in the vehicle’s production process to cut lead times and costs by rapidly prototyping designs and printing strong, end-use parts that could resist the elements.

The electric off-roader is now entering final production, and the company intends to keep using Shapeways’ services to create end-use parts in future. “Right now we are moving to production, and most of the parts that had previously been tested with 3D printing are now thermo or injection molded,” said Michael Martel, Head of Product Development at MTT. “The other 10 parts that are needed for an MTT-154 2020 will continue to be built with 3D printing technologies.”

Business news: PORT.im launches data security service

Personal data security firm PORT.im has launched a new smart privacy service designed to help SMEs stay compliant with GDPR data protection legislation. The software combines online digital tools, one-to-one expert guidance, and optional data protection insurance, to prevent businesses falling foul of the legislation.

PORT’s new smart privacy app also guides users through an intuitive discovery process that generates all the company’s privacy documentation and keeps them up-to-date with GDPR regulations. The mobile app also generates a ‘GDPR score,’ and gives businesses a measure of their compliance to date, and provides the added goal of increasing their score to earn PORT’s GDPR best practice badge.

“Since the introduction of GDPR, businesses have struggled to understand what they need to do. COVID-19 has made the situation worse as many companies are now handling more personal data about their customers and staff,” said Julian Saunders, CEO of PORT.im. “With our new service, we are giving small businesses a simple and affordable way to make themselves safe from the perils of GDPR and build trust with their customers.”

3D printing investments made in Navatek and SavorEat

The Department of Defense naval research company Navatek and the University of Maine have been granted a $5 million contract by the Office of Naval Research (ONR). Additional funding will be used by the companies to advance 3D printing materials and manufacturing processes for the construction and optimization of Navy and Marine Corps vessels. The aim of the project is to improve the speed and range of naval boats during missions while simultaneously reducing costs and the associated lead times.

“Our research, advanced manufacturing and testing will help open the design space for 3D printed parts and frameless additive manufacturing to be applied to new vessels for the Navy,” said Habib Dagher, Executive Director of University of Maine’s Advanced Structures and Composites Center (ASCC). “This project is a result of UMaine’s work last year where we commissioned the largest polymer 3D printer in the world at UMaine-ASCC and 3D printed a 25-foot-long, 5,000-pound patrol vessel.”

Israeli 3D printed food start-up SavorEat has also received significant investment, gaining $4.75 million from the Mor and Meitav Dash investment houses and the Millenium FoodTech Partnership. The 3D printing start-up, founded in 2018, uses a mixture of 3D printing technology and advanced cooking methods to produce plant-based alternative meats. Utilizing their technique, which SavorEat describes as being like a “robotic chef,” meals can reportedly be customized in multiple dimensions, without the need for human contact.

“We believe that only quality and healthy alternatives to meat will succeed in leading the desired change of reducing meat consumption,” said Racheli Wizman, CEO of SavorEat. “Through the latest recruitments we will work to realize this concept and bring to the market a unique technology that can lead the foodtech market.”

New 3D printing materials from Nexa3D, Arkema, 3DPRINTUK

SLA 3D printer manufacturer Nexa3D has launched a new environmentally-friendly washing solvent for resin-based 3D printers called xCLEAN. Designed to work with most photopolymer 3D printers, the chemical eliminates greasy residue and reportedly lasts three times longer than the commonly-used isopropyl alcohol (IPA). According to Nexa3D, xCLEAN is also safer to handle than other cleaning solvents, and does not require any special storage or adherence to shipping regulations.

“I am very proud of our entire team for stepping-up during this unprecedented pandemic, and quickly pivoting internal developments and external collaborations to adeptly support our growing customer base and communities,” said Avi Reichental, Co-founder and CEO of Nexa3D. “Throughout this challenging period, we’ve continued to expand the range of our high impact, durable photoplastics.”

3D printing services provider 3DPRINTUK has introduced a new polyether block amide (PEBA) printing polymer called PrimePartST. PEBA 2301 exhibits flexible, rubber-like characteristics similar to Thermoplastic Polyurethane (TPU) while reportedly demonstrating good chemical resistance, and long term stability. The thermoplastic also has a high melting point, making it well-suited for end-use in applications such as making air ducts, door handles and seals or gaskets.

3DPRINTUK has also acquired a PowerShot S system from DyeMansion, enabling it to offer a post processing service for low, medium, and high volumes of components. The machine, which utilizes DyeMansion’s proprietary PolyShot Surfacing (PSS) process, yields parts with a smooth, matt-glossy finish and scratch resistance qualities. The PowerShot S also has a cycle time of just 10 minutes compared to an estimated six hours required to finish parts using traditional tumbling methods.

“At 3DPRINT UK we have honed and optimized the SLS 3D printing process over many years to achieve the best possible results off our machines for a wide range of relevant applications that continue to grow in scope,” said Nick Allen, 3DPRINTUK’s CEO and Founder. “Expanding our post processing capabilities is a vital part of the business, and the DyeMansion PowerShot S system is an important next step in our expansion.”

3D printing materials company Arkema has extended its partnership with US-based start-up Continuous Composites. Having signed a Joint Development Agreement (JDA) in September 2019, Arkema has now made a further investment in the company to drive the development of its CF3D printing technology. The businesses are also working together to produce N3xtDimension photocurable resins which are specifically designed for use within the CF3D process.

“We are delighted to strengthen our strategic partnership with Continuous Composites, which has an agile, reliable team with a very strong entrepreneurial spirit,” said Sumeet Jain, Senior Director of 3D Printing Worldwide at Arkema. “Our investment is a testament to our belief in the market opportunity of CF3D. This collaboration will accelerate the development of innovative materials and disruptive manufacturing technology.”

3D Hubs releases Supply Chain Resilience Report

Finally, on demand manufacturing platform 3D Hubs has released the results of its Supply Chain Resilience Report 2020. The company’s research, which surveyed more than 36,000 businesses, concluded that the COVID-19 pandemic had damaged supply chains more than sanctions, cyber attacks and natural disasters combined. Six out of ten firms are now targeting supply chain diversification following the COVID-19 outbreak, but 52 percent of those have admitted that they have yet to begin this process.

“This pandemic has highlighted the true extent of supply chain vulnerabilities, undermining entire industries and countries,” said Bram de Zwart, CEO and Co-founder of 3D Hubs. “While no sure way exists to mitigate risks, having access to a decentralised manufacturing ecosystem provides the ability to react to, and model for, unforeseen events.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of a Continuous Composites carbon laser. Image via Continuous Composites.