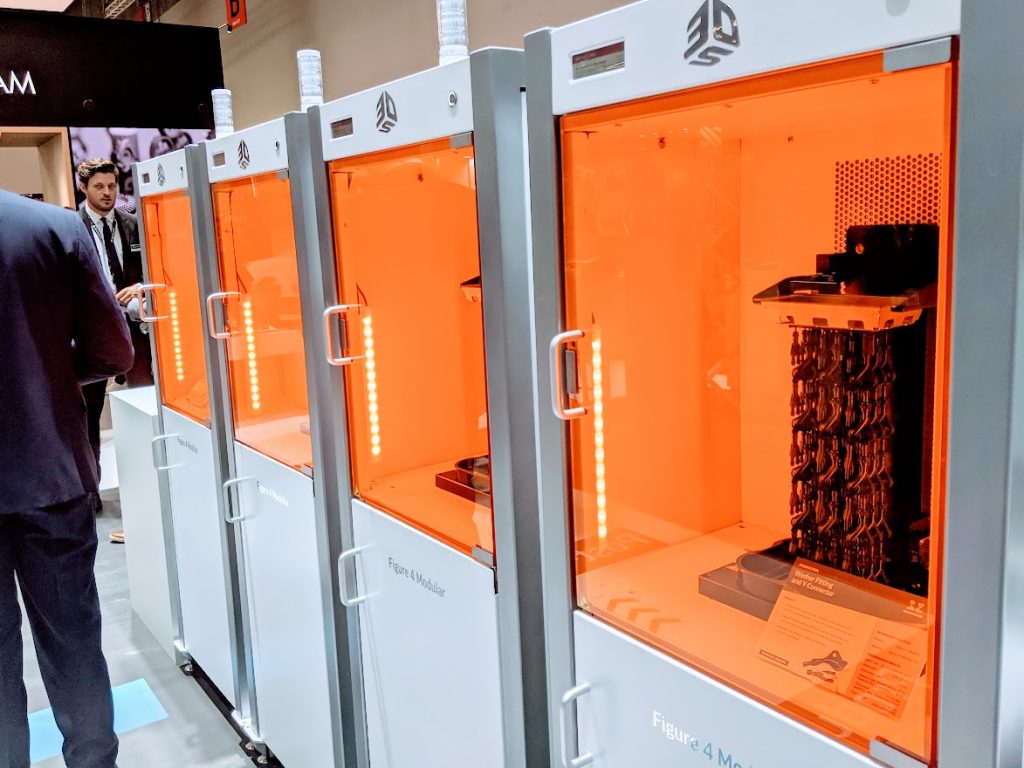

3D Systems, the North-American manufacturer of 3D printers, has announced a business cooperation with TE Connectivity, a global leader in connectors and sensors. The project will jointly develop an additive manufacturing solution for producing electrical connectors that fulfill demanding UL regulatory criteria. The solution, which included t3D Systems’ Figure 4 Modular 3D printer, the resin 3D printing material, and 3D Sprint software, and services, was created to fulfill TE Connectivity’s specific material performance and high tolerance, dependable printing requirements. The solution is built around a newly developed photopolymer 3D Systems created specifically to fulfill the needs of TE Connectivity. It is the first known printable photopolymer to complete a UL®1-recognized long-term thermal aging (RTI) research, in addition to having a world-class flammability rating at 0.4mm thickness.

TE Connectivity is a worldwide industrial technology pioneer dedicated to making the future safer, more sustainable, productive, and connected.

Philip Gilchrist, VP and segment chief technology officer for Communications Solutions at TE Connectivity explained that as 3D printing technology advances, TE Connectivity anticipates increasing prospects for employing it to produce goods for customers who require a limited volume of parts in a short period of time. With the collaboration with 3D Systems, TE Connectivity can offer functional components to our clients in weeks rather than months.

This material, when paired with an efficient print process, provides the requisite dependability and accuracy for TE Connectivity’s products. The combination of novel material qualities, speed, and accuracy enabled the manufacturing of robust industrial products for the first time, aimed for appliances, cellular, and data-center applications, using 3D Systems’ Figure 4 technology. TE Connectivity may use additive manufacturing to build intricate geometries that would be impossible to create using injection molding. It improves flexibility for low-volume, quick-turn production runs and tooling avoidance, allowing TE to swiftly demonstrate its capabilities and clients to satisfy demand more efficiently.

The Applied Innovation Group (AIG) of 3D Systems worked with the team at TE Connectivity to create a full production workflow from design to manufactured connector. A new Figure 4 material was developed and UL certified as part of the initiative. UL regulatory approval has been acquired, including UL94 V0 flame rating at 0.4mm, Glow Wire Ignition (GWI) of 800°C, Comparative Tracking Index (CTI) of 600V (equal to a PLC of 0), and Relative Temperature Index (RTI) of 150C and 130C, respectively, for long-term electrical and mechanical operation.

“Customer-centric innovation is at the core of everything we do,” said Reji Puthenveetil, executive vice president, industrial solutions, 3D Systems. Working with TE Connectivity helped the development of the solution by providing an understanding of the unique application being addressed. Puthenveetil explained the 3D Systems materials scientists and 3D print process experts worked closely with the TE team to develop a material that, when combined with our Figure 4 technology, met the high quality and reliability criteria that their customers have come to expect. Puthenveetil said this project is just another example of 3D Systems’ collaboration with industry leaders to accelerate innovation and create competitive advantage through additive manufacturing technologies.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D Systems Figure 4 Modular 3D printer. Photo by Michael Petch.