Technology startup SelectAM has announced new software for automated part identification of components made using a 3D printer.

Able to be integrated into existing PDM, PIM, and ERP systems, the automated part screening software is designed to help manufacturers unlock additive manufacturing production’s full potential. SelectAM’s starting partners include software and manufacturing companies within Europe looking to scale up their 3D printing production capabilities.

Encouraging the switch from conventional manufacturing to AM

SelectAM was founded in 2020 by an international team of additive manufacturing experts and software developers. The startup began as a spin-off from a research project carried out by Aalto University in Finland, which created a 3D printing database that aimed to help manufacturers identify the potential time and cost savings of additive manufacturing, and ultimately encourage more businesses to switch to 3D printing in favor of conventional methods.

As conventional manufacturing businesses are increasingly challenged with rethinking the way they produce their products, 3D printing could provide gains for these businesses as they transition to a more digital manufacturing approach. Senvol is the largest additive manufacturing database in the industry and is leveraged by multiple sectors to aid process integration.

Other similar platforms include American manufacturing association SME’s Interactive RAPID AM Portal (iRAMP) which helps businesses to see if 3D printing could benefit their operations, and a feasibility model developed by researchers at Tampere University of Technology and industrial engineering firm Enmac Oy.

Automated part screening

SelectAM’s automated part identification and re-design software is designed to provide manufacturers looking to scale up their 3D printing operations with specialized tools to facilitate this transformation efficiently. In short, the platform allows businesses to screen and identify how they can streamline production through implementing 3D printing processes and how they can scale up their activities in this area.

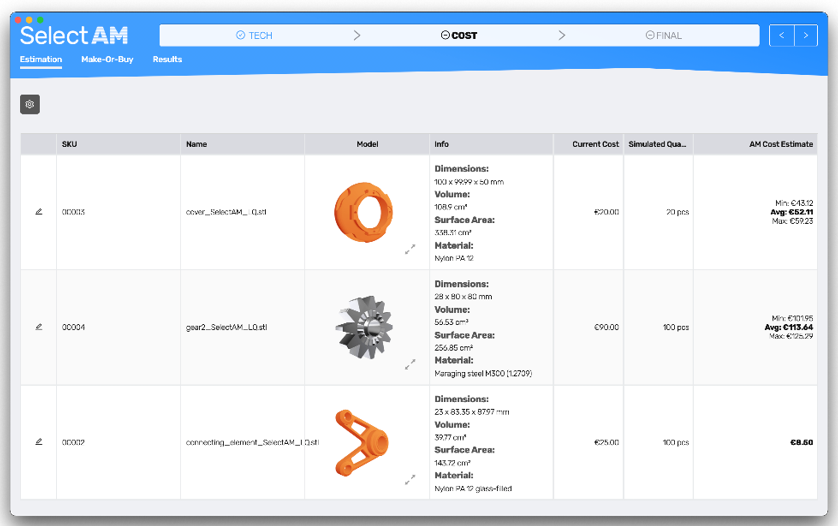

The part identification feature considers the technical, economic, and design potential of customers’ components and their supply chains. At the same time, the platform provides a simulation of the industrially relevant additive manufacturing technologies and post-processing steps that could be suitable.

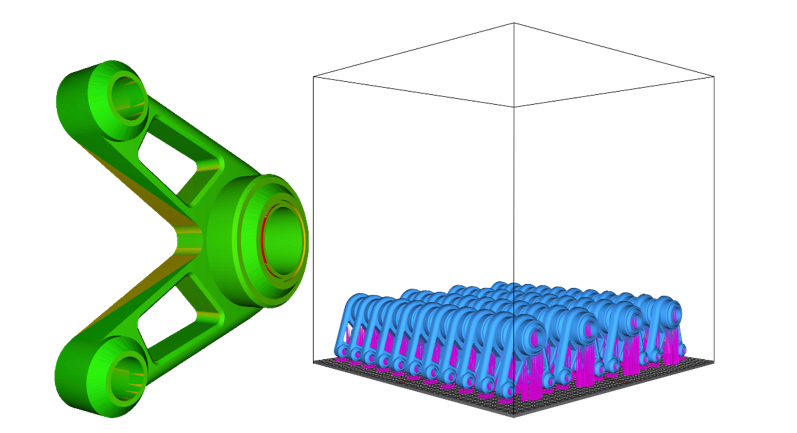

Additionally, the software offers an up-to-date database of end-use 3D printer materials and their manufacturing capabilities. Assisted by machine learning, the software provides cost and pricing simulation with or without 3D models, alongside nesting visualizations to aid customers in decision-making and production optimization.

The platform is also equipped with full offline functionality and customers have the option of on-site installation in order to comply with strict data export regulations. SelectAM can determine the total cost for a customer to switch to 3D printing through a comprehensive make-or-buy analysis that provides both part inventories and single part-to-part comparisons.

So far, SelectAM has analyzed in the region of 16,000 component types in collaboration with its starting partners throughout Europe. The firm is now rolling out its 3D printer automated part identification software further afield in a bid to further the adoption of additive manufacturing across a wide variety of sectors.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows wall thickness analysis and part nesting in SelectAM’s automated part identification software. Image via SelectAM.