The U.S. National Institute of Standards and Technology (NIST) has awarded Senvol, the largest online database of 3D printing systems and materials, a total sum of $99,946 for a project applying data analysis to additive manufacturing processes.

The end goal of the project is to develop a tool that will increase the adoption rate of additive manufacturing throughout U.S. industry, maturing factors like material characterization for the purpose of certification.

Continuous learning

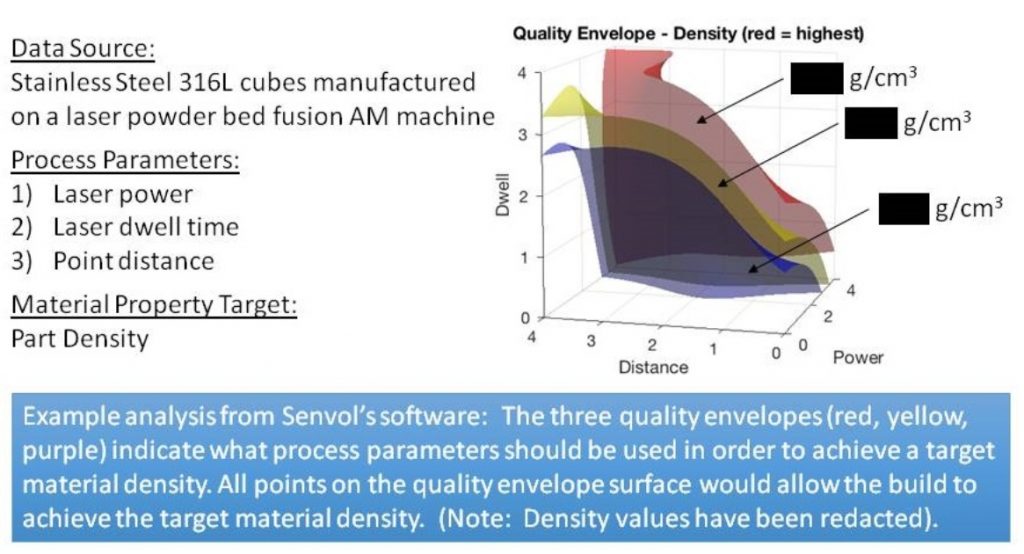

Senvol’s project is titled “Continuous Learning for Additive Manufacturing Processes Through Advanced Data Analytics.” For the project, Senvol will supply its machine learning software to analyse data input from NIST test studies and the institute’s Additive Manufacturing Benchmark Series. This input includes, according to the official project abstract, “in-situ monitoring data, microstructure data and non-destructive testing (NDT) data.”

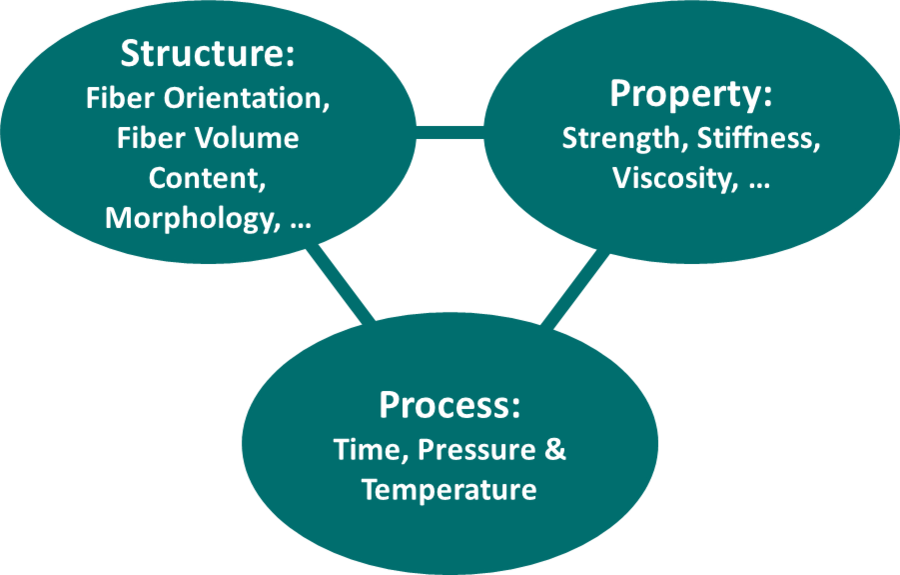

As such, the project will work to establish Process-Structure-Property relationships for materials. This will make it easier for manufacturers to analyse their additive manufacturing processes, resulting in faster qualification for 3D printed products that better matches the rate of traditional manufacturing processes.

The power of data-driven machine learning

By the end of the project, Senvol Machine Learning will be integrated into NIST’s AM Material Database (AMMD) to create a “continuous” loop of analysis.

Yan Lu is a NIST Senior Research Scientist who will be working on the project with Senvol. According to Lu, “The work in this project will demonstrate the power of a data-driven machine learning approach for additive manufacturing process understanding and material characterization,”

“Furthermore, Senvol will showcase hybrid modeling, whereby physics-based models and data-driven models are joined under a single framework.

NIST and Senvol innovations

Recently, Senvol launched a similar data-driven additive manufacturing project with U.S. Navy’s Office of Naval Research. The company has also joined the National Armaments Consortium (NAC) to play a role in the “rapid innovation” of U.S. military equipment.

NIST’s other additive manufacturing research projects includes the characterization and impact assessment of recycled powder with Sigma Labs, and development of the Additive Manufacturing Metrology Testbed (AMMT).

For all the latest updates on the projects mentioned in this article subscribe to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

Search and post 3D Printing Jobs to seek opportunities and new talent across engineering, marketing, sales and more.

Featured image shows engineering drawing of the NIST test artifact for 3D printing. Image via NIST