A team of researchers from the University of Tübingen and the Graz University of Technology have 3D printed a robotic arm capable of mimicking the movements of an elephant’s trunk.

Equipped with a gripper on the tip, the FDM-printed robot uses machine learning to roam around and adapt to new tasks, such as picking up marbles and placing them on podiums. Developed as a low-cost proof-of-concept, the design could eventually go on to be used on an industrial production line where it would be capable of performing a wider variety of flexible operations, such as transporting automotive parts or assembling electronic devices.

Dr Sebastian Otte, a co-author of the study, told New Scientist, “Our dream is that we can do this in a continuous learning set-up where the robot starts without any knowledge and then tries to reach goals, and while it does this it generates its own learning examples.”

Industry 5.0: Elephant trunks

Elephant trunks are one of evolution’s finest works. They are equal parts flexible and strong, and provide elephants with a level of dexterity you don’t often see in the animal kingdom. As a result, they are a source of inspiration for many modern bionics projects in academia, with pneumatic actuators often acting as artificial muscle fibers to achieve bending and extension.

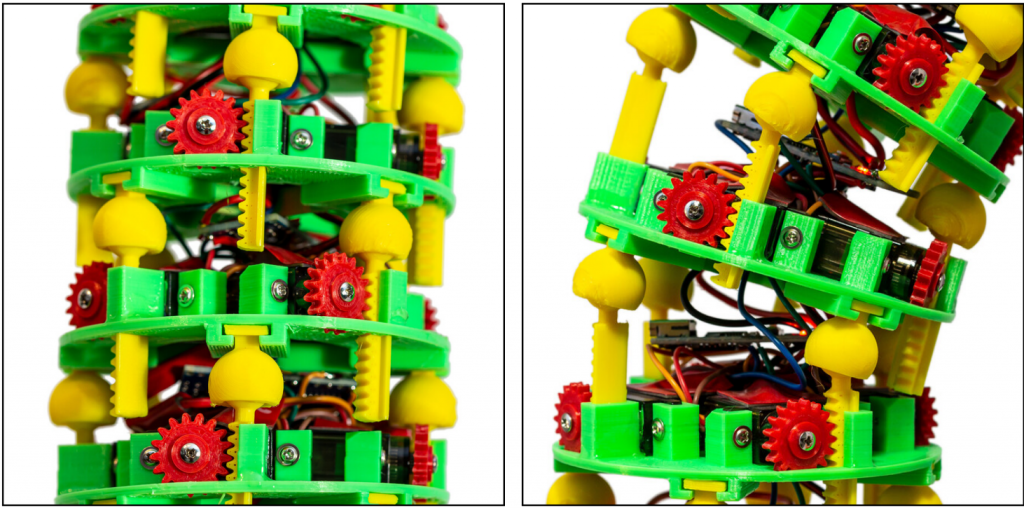

Otte and his colleagues opted for a modular design, which is based on a set of uniform, stackable joint modules with three degrees of freedom (DoF) each. The current design features up to ten of these modules, but the length of the robot can reportedly be doubled with the use of more powerful motors.

Each segment in the trunk houses several motors driving gears that can tilt the module up to 40° in two axes at once. As well as bending, the robotic trunk is also capable of lengthening and shortening – just like the real thing. Unfortunately, calculating the inverse kinematics for robotic actuators to perform complex operations is no easy task, even less so with this many DoFs. This is where artificial intelligence comes in.

Spiking neural networks for navigation

The team used what’s called a spiking neural network (SNN) to control the robot, which is an artificial neural network that closely mimics natural brain processes. As well as incorporating neuronal and synaptic states, SNNs also include the concept of time in their models. By observing a set of training movements, the SNN was able to map motor movements to corresponding robot poses, enabling the team to ‘unroll’ the models for goal-driven navigation with near-millimeter precision.

The researchers write, “We not only showed that it is possible to construct low-cost trunk-like robotic arms with basic 3D printing equipment, but we also demonstrated how they can be controlled using the latest recurrent spiking neural network architectures.”

As far as future research goes, the team has expressed the possibility of incorporating radar-based distance sensors to implement collision avoidance functionality, enabling the device to work in tandem with humans. Another route could be to translate the work into a snake-like robot rather than a stationary arm, whereby it could ‘slither’ around for search and rescue operations.

Further details of the study can be found in the paper titled ‘Many-Joint Robot Arm Control with Recurrent Spiking Neural Networks’. It is co-authored by Manuel Traub, Robert Legenstein, and Sebastian Otte.

Low-cost robotics is a prime example of how 3D printing can be applied to solve abstract problems. A team of researchers from Meiji University, Tokyo, recently customized an FDM 3D printer to create a low-cost ‘all-in-one’ manufacturing robot. The Functgraph is capable of automatically printing and attaching custom tool heads to change its active functionality, enabling users to grab, rotate, and break 3D printed objects to assemble complex mechanical systems in a single print job.

Elsewhere, scientists at China’s Tianjin University have previously 3D printed a customizable robot that’s capable of scaling and monitoring pipes at industrial facilities in real-time. The single-piece device features a series of soft bending mechanisms and modular grippers, allowing it to flexibly climb oddly-shaped infrastructure.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the trunk robot at full flexion. Photo via University of Tübingen.