A team of seven researchers from various U.S. universities have published a study evaluating the accuracy of 3D printed medical models.

Unlike similar studies, which tend to focus on a single organ and pathology, the work covers medical models spanning multiple pathologies, making it more comprehensive in nature. The study is also unique in that it focuses exclusively on the resin-based Formlabs Form 3B 3D printer, which is used extensively in medical institutions for dental, surgical planning, and educational applications.

The importance of precision

In the healthcare sector, 3D printing is increasingly being used for everything from anatomical models to surgical guides and medical implants. Many hospitals and medical centers even have in-house 3D printing labs, which is often referred to as point-of-care 3D printing.

Of the applications, the 3D printing of medical models is among the most developed. When combined with 3D scanning and X-ray technologies, these tools can be a very important part of patient care, and act as a more accessible alternative to cadavers. 3D printed medical models allow surgeons to better prepare for upcoming treatments and surgeries by providing a visual method of understanding the spatial and anatomical relationships between tissues and organs.

Unfortunately, there’s no agreed-upon standard when it comes to clinically-acceptable measurement accuracy, but a dimensional precision of under 1mm is assumed to be adequate. If there are defects and precisional inaccuracies in these 3D printed models, this could result in poor treatment planning, potentially putting patients in harm’s way. As such, there remains a need to understand how model accuracy can be affected by certain parameters such as the material used, the geometry of the model, and the orientation of the build.

How did the Form 3B stack up?

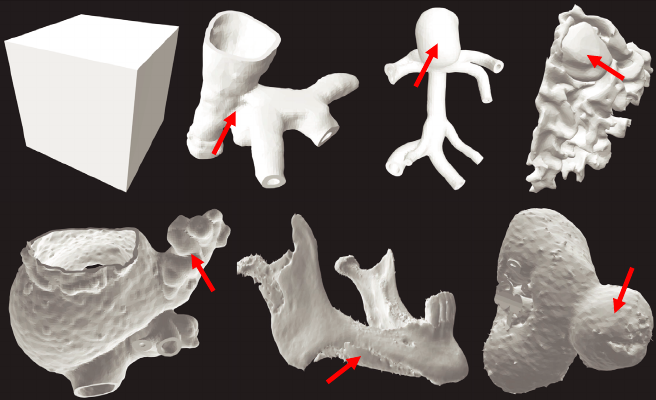

The U.S. team started off by 3D printing seven different models – six anatomical models and one reference cube – in three resins (Elastic, Clear, and Grey Pro). The anatomical models were designed to cover several common pathologies, including neurological, cardiovascular, abdominal, and musculoskeletal.

When it came time to measure the accuracies of the models, the team created two solid measurement landing blocks around each of the pathologies and quite simply used a high-precision digital micrometer. These measurements were compared to the designed dimensions of the corresponding 3D files.

Looking at the results, the maximum absolute error was less than 1mm across all of the models, with an average absolute error of around 0.25mm. Interestingly, hollow models were significantly less accurate than solid models and elastic models were less accurate than their rigid counterparts. While there was no difference in accuracy between the 0.1mm and 0.05mm layer height settings, medical models that were oriented horizontally (shorter) in the build chamber were found to be less accurate than those oriented vertically (higher z-height).

Many of the results can be attributed to the physics of inverted desktop SLA 3D printing, specifically relating to the forces caused by the peeling of the parts from the bottom of the vat. Still, with dimensional precisions in the sub-1mm range, the Formlabs Form 3B was determined to be adequately accurate for the 3D printing of medical models, provided the parts were solid and made of a rigid resin.

Prashanth Ravi, a co-author of the study, concludes, “I believe this paper makes a valuable contribution to the growing literature surrounding this topic by marrying anatomical model accuracy with the underlying process physics for the very first time within the medical 3D printing sphere.”

Further details of the study can be found here. The paper is co-authored by Prashanth Ravi, Leonid Chepelev, Nathan Lawera et al.

Just last year, a similar study from the Queensland University of Technology challenged the accuracy of the FDM 3D printing process when it came to additively manufactured anatomical reconstructions. The research team was able to demonstrate that changing the slice reconstruction interval of the build had a significant impact on the spatial replication accuracy of the 3D printed models.

Elsewhere, in the bioprinting sphere, researchers from Carnegie Mellon University have previously developed a method of 3D bioprinting fully-sized human heart models. The scientists’ Freeform Reversible Embedding of Suspended Hydrogels (FRESH) technique involves extruding an eco-friendly alginate polymer into a custom-made gelatin container.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Formlabs Form 3B 3D printer. Photo via Formlabs.