A team of researchers from Meiji University, Tokyo, have customized a low-cost FDM 3D printer to create an ‘all-in-one’ manufacturing robot.

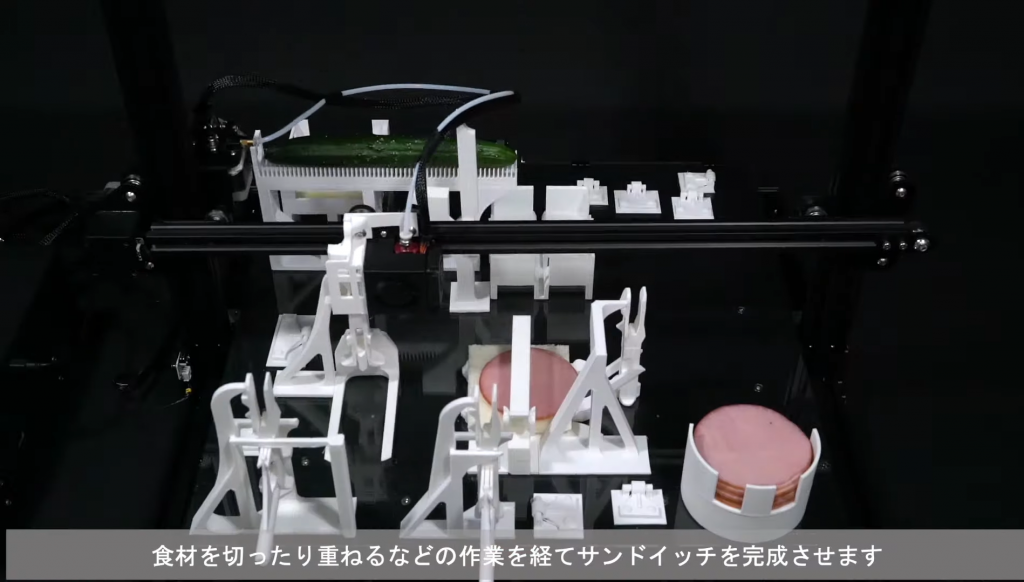

The Functgraph, as it’s called, is capable of automatically printing and attaching custom tool heads to change its active functionality. This grants users the ability to grab, rotate, and break 3D printed objects to assemble more complex mechanical systems in a single print job. To demonstrate the custom robot’s capabilities, the team has already used it as a sandwich maker, a t-shirt folder, an end-to-end toy car assembly line, and more.

The Meiji team wrote, “We introduce new ways of using a 3D printer head as a 3-axis robotic manipulator to enable advanced fabrication and usage such as assembling separately printed parts, breaking support materials, and actuating printed objects on a build plate.”

Eliminating human intervention

As advanced as modern-day FDM systems are, the end-to-end 3D printing workflow is still a highly manual one. Once the 3D printing stage is complete, post-processing tends to require a human technician to remove the part from the build plate, remove all of the support structures, and integrate the part into an assembly if it is a component. This is the hurdle the Meiji team is trying to jump with the Functgraph.

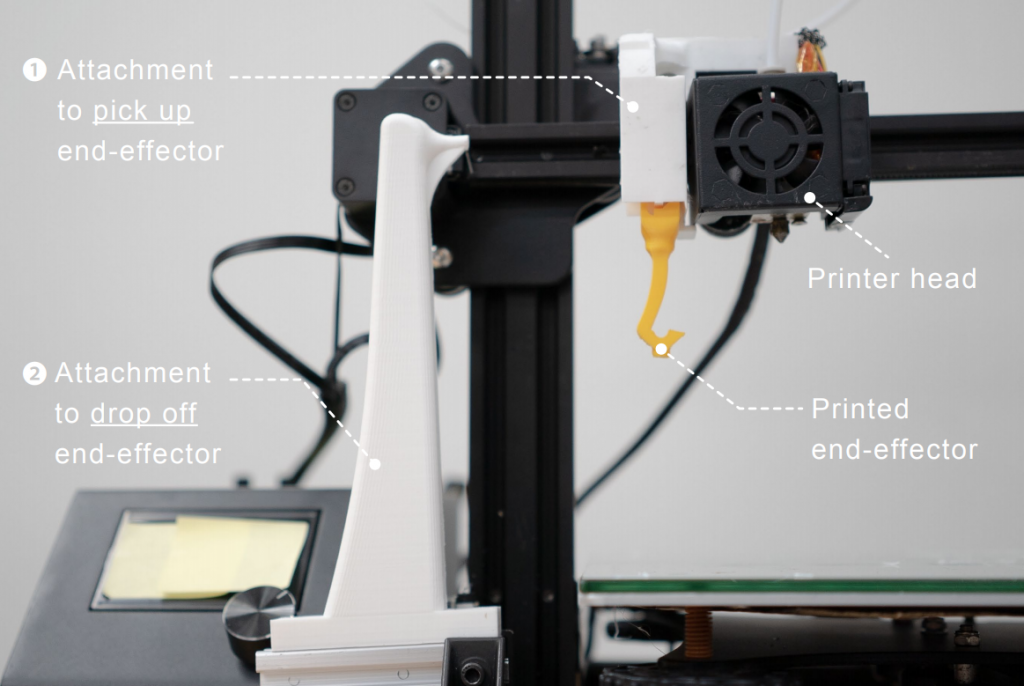

To kick the project off, the researchers first designed and 3D printed two custom tool head switchers – one for attaching end-effectors and one for detaching them. These switchers were designed to be integrated directly into a commercially-available Creality CR-10 3D printer and operate with a very simple clip-on/clip-off mechanism.

With the end-effector switchers in place, the team developed a custom gcode generation program which involved just three main operations: printing the necessary components and end-effectors, picking up the end-effectors, and applying the end-effectors to the printed components.

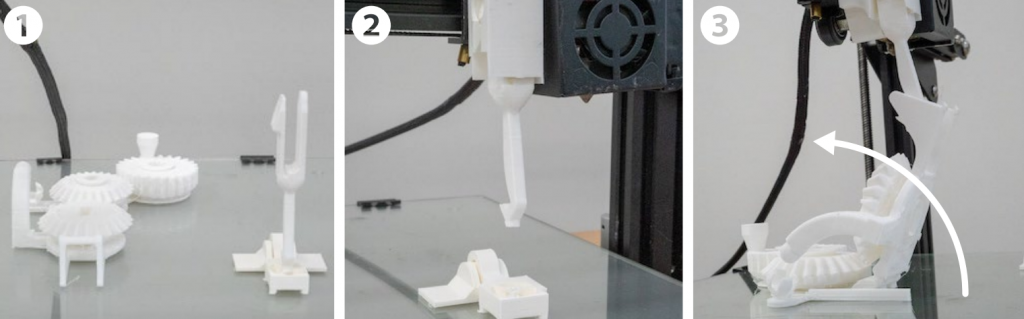

This is demonstrated in the example below, where the researchers used the Functgraph to print and assemble an entire bevel gear system from scratch. Firstly, the individual gears were printed flat and unassembled on the build plate, along with the end-effector necessary to assemble them (a hook). The printhead then peeled the hook off the bed and used it to fold each of the gears into the final mechanical assembly – all with one gcode file.

Combining four key advanced fabrication techniques

Of course, printing hooks and folding components will eventually exhaust its use cases, so the team developed four key fabrication movements that could be used in conjunction with each other for more advanced projects. Folding is the first of these, and can be used to snap components together using printed hinges and ball and socket snap-fit mechanisms.

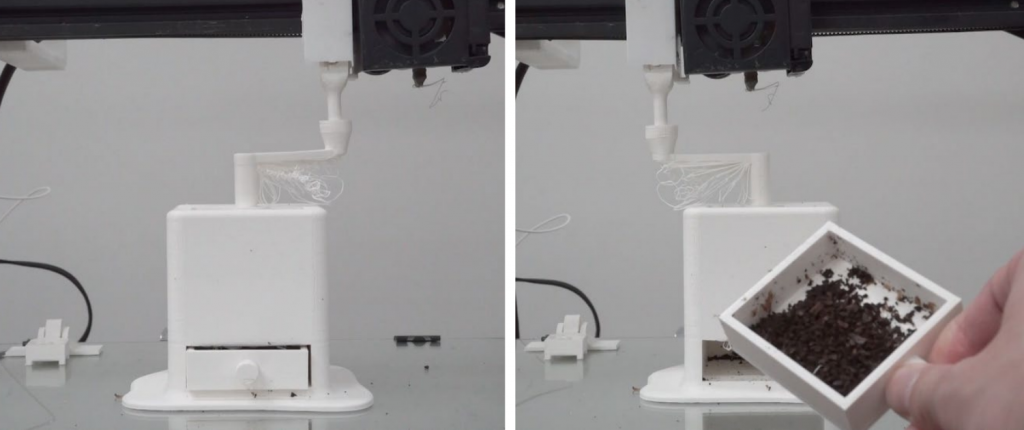

The second key operation is actuation, which is a rotation-based movement. Demonstrated with a small-scale coffee mill, actuation can be used to grind up coffee beans and perform other circular motions.

Breaking support structures is the third key movement, and it enables users to free their printed components from their supports by leveraging the printer’s Z-axis motor and a rod-like end-effector acting as a spear.

Last but not least, the Functgraph also features a sliding operation. Sliding is perhaps the most crucial movement, as it allows users to slide objects into each other to create assemblies or even perform cutting motions on food using a blade end-effector. By intelligently using combinations of these four operations, the Functgraph is able to serve as an adaptable manufacturing robot for a whole host of creative applications.

Further details of the project can be found in the paper titled ‘A 3D Printer Head as a Robotic Manipulator’. It is co-authored by Shohei Katakura, Yuto Kuroki, and Keita Watanabe.

Custom 3D printing systems like the Functgraph are rife in the academic field. Earlier this year, researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) developed a hardware add-on that transforms commercial laser cutting systems into hybrid 3D printers. Named LaserFactory, the electromechanical assembly attaches to a laser cutter’s head, resulting in a comprehensive fabrication platform that can be used to create and assemble fully functional electronic devices such as drones.

Elsewhere, at the Technical University of Denmark (DTU), researchers recently repurposed a component from a Microsoft Xbox 360 to develop a high-resolution nanoscale 3D printer with various applications in the medical sector.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Functgraph being used as a sandwich maker. Photo via Meiji University.