A team of researchers from the University of Freiburg, together with materials startup Glassomer, have developed a new polymer-based silica glass material compatible with injection molding technology.

When used in conjunction with 3D printed molds, the composite material enables the high-throughput production of complex glass components with previously impossible geometries. The team, led by Prof. Dr. Bastian Rapp from the university’s Laboratory of Process Technology, expects potential applications in everything from optical devices to solar technology and lab-on-a-chip medical devices.

Dr. Frederik Kotz, group leader at the Laboratory of Process Technology and Chief Scientific Officer at Glassomer, states, “We see great potential, especially for small high-tech glass components with complicated geometries. In addition to transparency, the very low coefficient of expansion of the glass also makes the technology interesting. Sensors and optics work reliably at any temperature if the key components are made of glass.”

A new approach to glassmaking

For millennia, glass has been the go-to material for aesthetic, see-through parts. Today, the material is used in everything from bottles and windows to high-tech telecommunication devices. The shaping of glass components is predominantly based on processes such as melting, grinding, etching, and kiln casting – all of which are slow, energy-intensive, and severely limited in terms of geometric freedom.

Injection molding, on the other hand, is the leading technology in the polymer industry. It is both rapid and cost-effective, making it well suited to series production with a wide variety of part types. According to the Freiburg team, transparent glass has not been compatible with high-speed injection molding technology until now.

“For decades, glass has often been the second choice when it comes to materials in manufacturing processes because its formation is too complicated, energy-intensive and unsuitable for producing high-resolution structures,” explains Rapp. “Polymers, on the other hand, have allowed all of this, but their physical, optical, chemical and thermal properties are inferior to glass. As a result, we have combined polymer and glass processing to quickly and cost-effectively replace both mass-produced products and complex polymer components with glass.”

Complex glass parts via injection molding

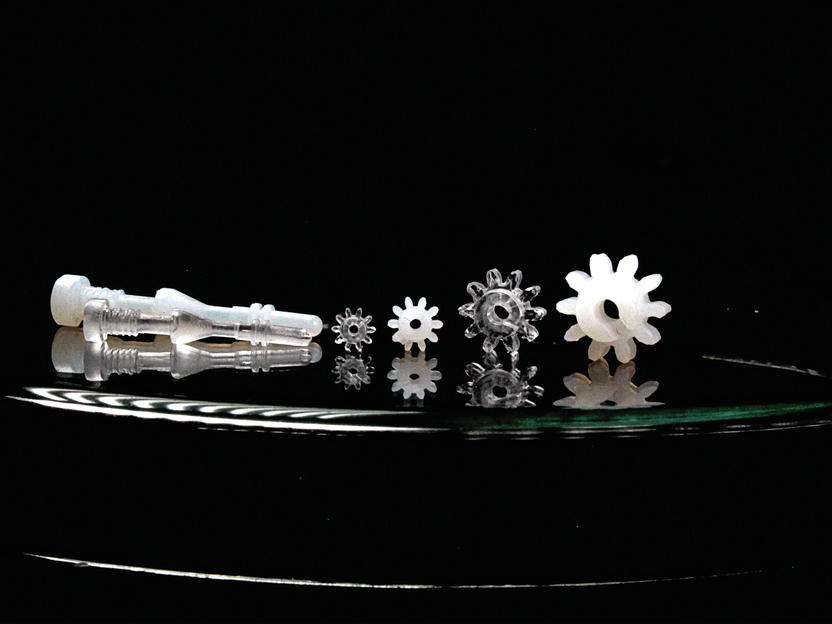

The newly developed material is a special composite granulate designed in-house by the researchers, and it is moldable at a low temperature of just 130°C. There is also a liquid resin version of the material that is compatible with SLA-based 3D printing.

When injected into a 3D printed mold, the material is initially a milky-white color, but can be converted into pure quartz glass via a heat treatment process. This can be done using far less energy than conventional glass melting, and the formed glass parts have a high surface quality so the need for further polishing is eliminated altogether.

To make the current work possible, the research team had to solve existing problems relating to material porosity and particle abrasion. In a bid to make the technology more environmentally-friendly, Rapp’s team also used water as a base material.

Kotz adds, “We have also been able to show that micro-optical glass coatings can increase the efficiency of solar cells. This technology can now be used to produce cost-effective high-tech coatings with high thermal stability. There are a number of commercial opportunities for it.”

Further details of the study can be found in the paper titled ’High-throughput injection molding of transparent fused silica glass’. It is co-authored by Bastian Rapp, Frederik Kotz, Markus Mader et al.

The combination of 3D printing and glass tends to be an eyebrow-raising topic, but there are a number of research institutions looking to advance the field. Scientists from the King Abdullah University of Science and Technology (KAUST) recently developed a new method of 3D printing photonic crystal fibers – a special type of optical fiber. The team constructed a purpose-built SLA-based 3D printer for the project, one that enabled the scientists to customize their optical fibers with previously impossible internal geometries.

Elsewhere, at Lawrence Livermore National Laboratory (LLNL), researchers have previously used multi-material 3D printing, namely direct ink writing (DIW), to fabricate highly customized gradient refractive index (GRIN) glass optics. The technique allows for a number of optical functions to be programmed directly into flat glass components – functions that would otherwise require curved lenses.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows glass gears injection molded using the new Glassomer material. Photo via Glassomer.