3D Printing Industry reviews the FlashForge Guider IIS 3D printer.

Designed and manufactured by the long-established FlashForge team, the Guider IIS (2S) is marketed as an “industrial-grade” single extrusion FFF 3D printer. Priced at $2,499, the system is based on the previously released Guider II and brings with it a whole host of quality-of-life upgrades.

As with many of the printers in its portfolio, FlashForge has gone the extra mile with the hardware of the Guider 2S. The 30kg full metal chassis is as sturdy as ever, with a transparent polymer door providing access to the build chamber. The machine has a respectable build volume of 250 x 280 x 300mm, complete with a 120℃ heated build plate to prevent warping on the undersides of prints. Included in the box is an optional acrylic overhead cover that fully encloses the build chamber, allowing for precise temperature control.

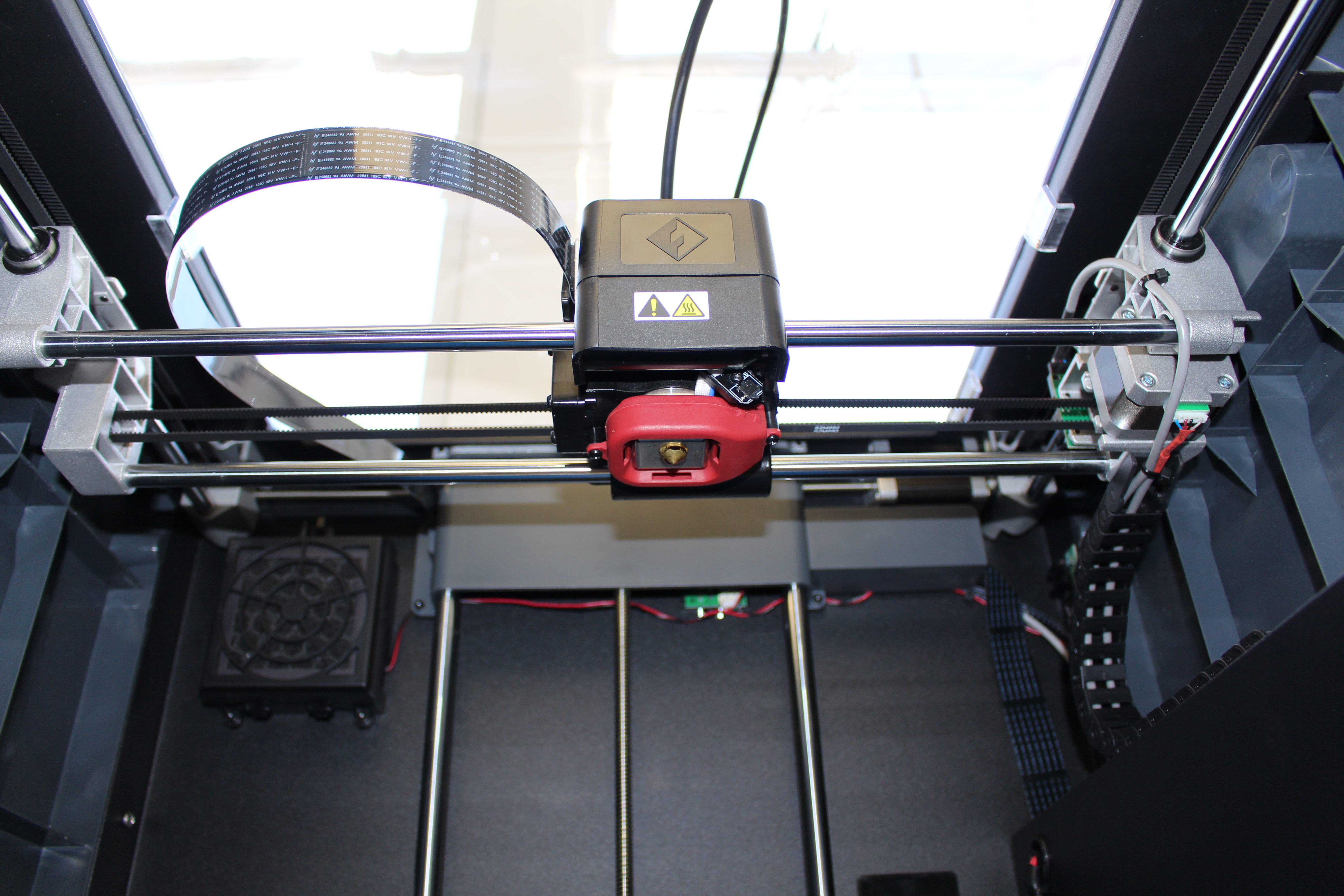

The single extruder has a maximum nozzle temperature of 300℃, and a maximum print speed of 150mm/s. The machine operates on a classical cartesian coordinate system, whereby the printhead travels along the X and Y axes, and the bed along the Z-axis. Claiming to be an open filament system, the Guider 2S should be compatible with a plethora of third-party filaments, including materials such as PETG, HIPS, and PC.

Unboxing and setting up

Like a giddy child on Christmas morning, we were more than excited to dive straight into the box of the Guider 2S. Much to our delight, the printer came packaged with everything you need to start and then some. FlashForge very kindly included a five-piece comprehensive nozzle kit for the machine (0.3mm, 0.4mm, 0.6mm, 0.8mm, and an additional hardened steel 0.4mm nozzle for carbon fiber printing). On top of this, a 1kg spool of white PLA, a 16gb USB to store models, and even a glue stick to aid with print adhesion.

Looking at the printer itself, it certainly is on the larger side at 550 x 490 x 570mm, but not so large that it won’t fit on a standard desk. The inclusion of a set of handles on either side of the frame makes it easy to carry and the external spool holder is thoughtfully placed on the back where it won’t be an eye-sore. On closer inspection of the machine, you’ll find an in-built HD camera for remote monitoring, a HEPA air filter for safer indoor operation, and a handy filament runout sensor – none of which were featured on the original Guider II.

It’s worth noting that the base print bed is made of glass, which comes covered with a magnetic stainless steel plate and a matte plastic sheet. While the sheet does provide better print adhesion, it is by no means mandatory and can be removed simply by detaching the magnetic plate. This is especially useful for users looking for smooth bases on their parts, as this can only be achieved with the flat surface of the glass underneath. The bed as a whole is guided by two rods for added stability.

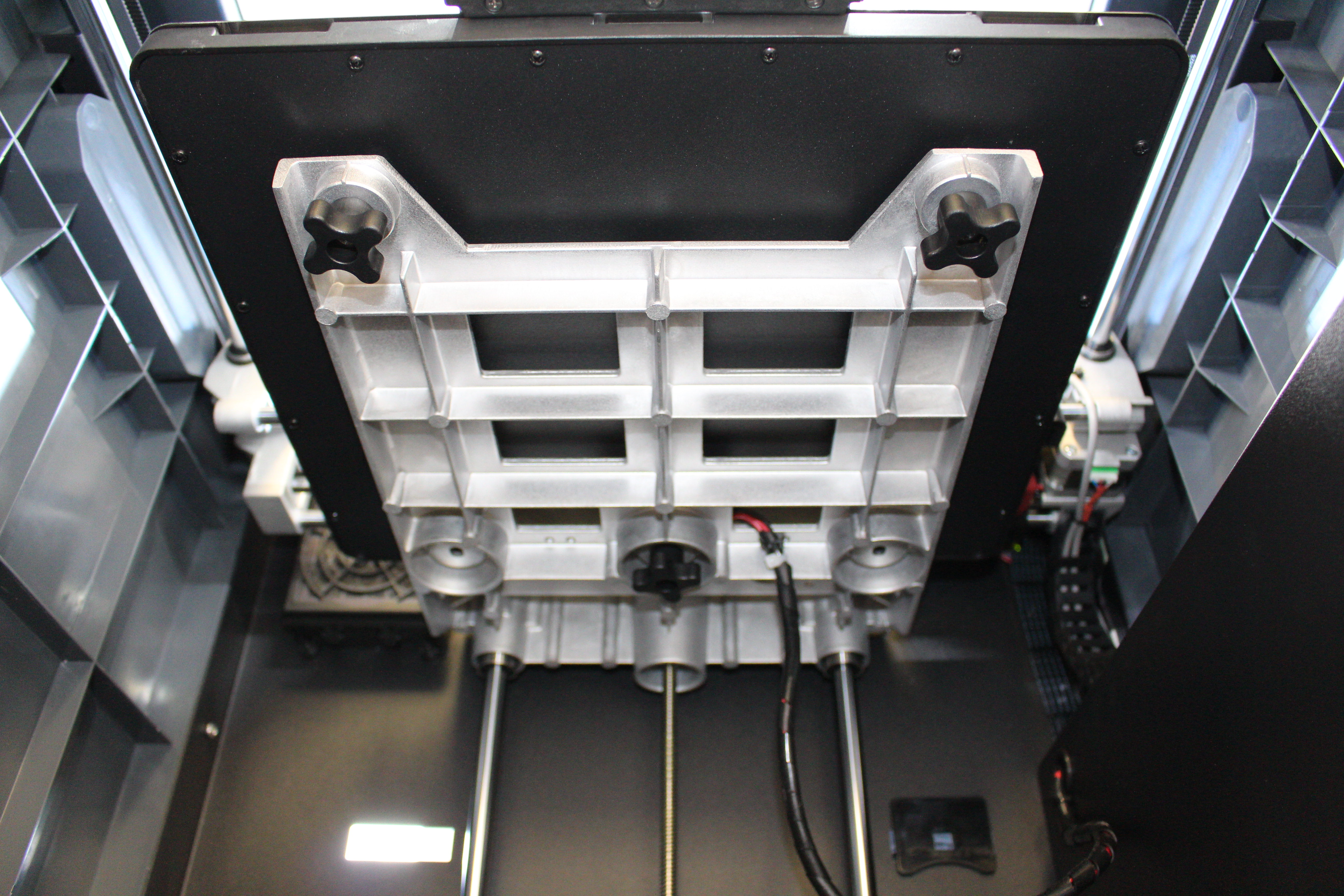

When it comes to actually leveling the bed, the full-color 5” touchscreen on the front of the printer guides the user with helpful graphics and animations. Once again, FlashForge has opted for a three-point leveling system, whereby three screws under the build plate control its height. With the bonus nine-point assisted leveling on the Guider 2S, the touchscreen tells the user which of the screws need to be turned and by how much. Once the in-built probe gives the go-ahead, the user is free to start printing.

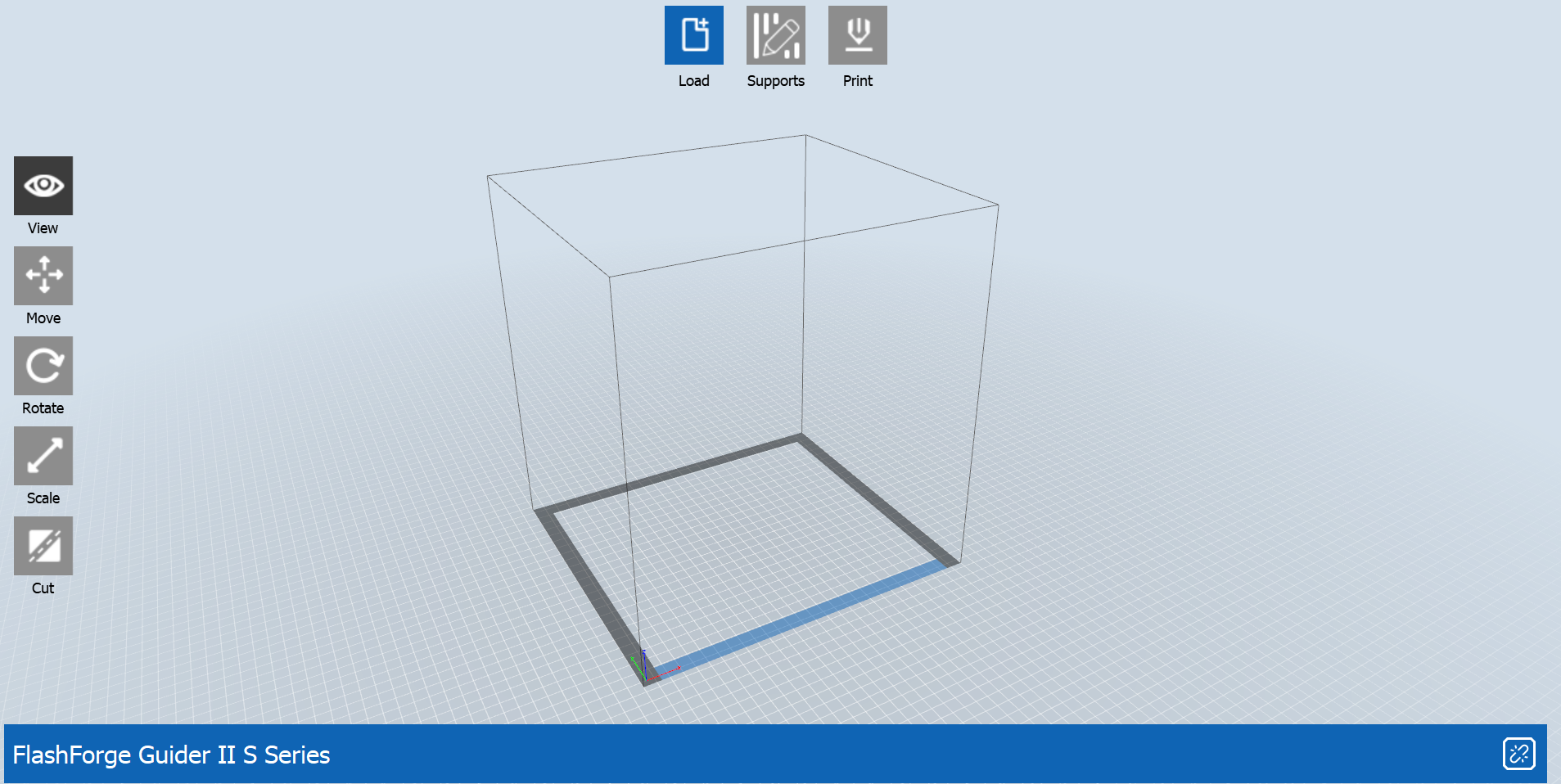

The FlashPrint Slicer

Unsurprisingly, FlashForge has again provided its own slicing software for use with the Guider 2S – FlashPrint. The sleek, minimalist UI is as clean as ever, with every individual element clearly labelled and distinguishable. The viewport itself is huge as a result of the lack of clutter, leaving plenty of space for model manipulation.

The basic translation, rotation, and rescaling functions are intuitive and responsive. Once the model is nested on the virtual build plate, the user is given the option to choose between two support geometries: linear and treelike. The support structures can be auto-generated to save time or added individually in a more precise point-and-click manner, although both work just fine in most situations.

For the 3D printing veterans out there, there is also an expert mode available. Using expert mode, users have access to the full range of print parameters for the utmost control over the printjob, including speeds, infills, and cooling profiles. Once the model is sliced, it can be transferred over to the printer via USB, Wi-Fi, ethernet, or using the completely remote Polar Cloud. All in all, FlashPrint does its job and it does it well – easy to use and refined.

Benchmarking the Guider 2S

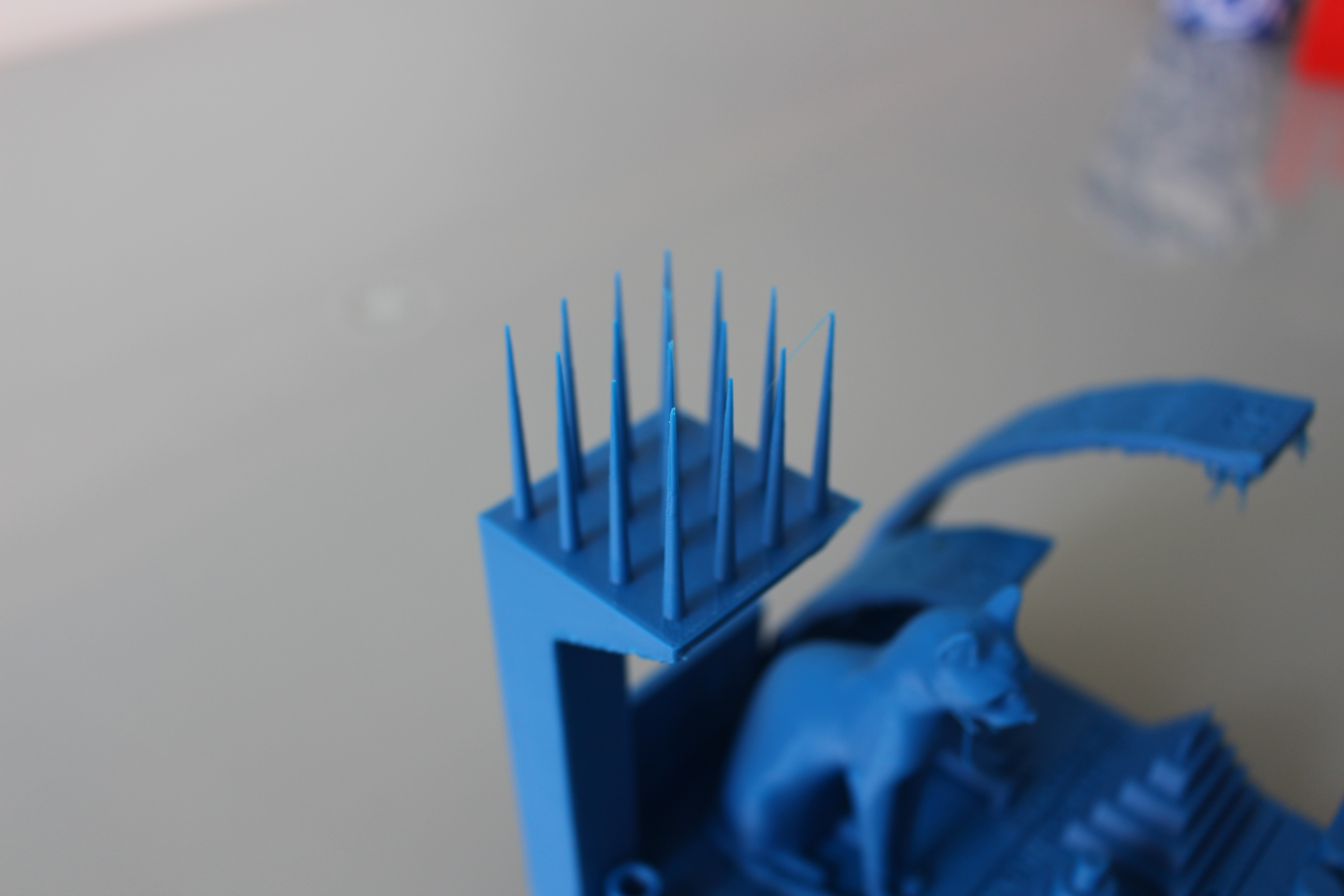

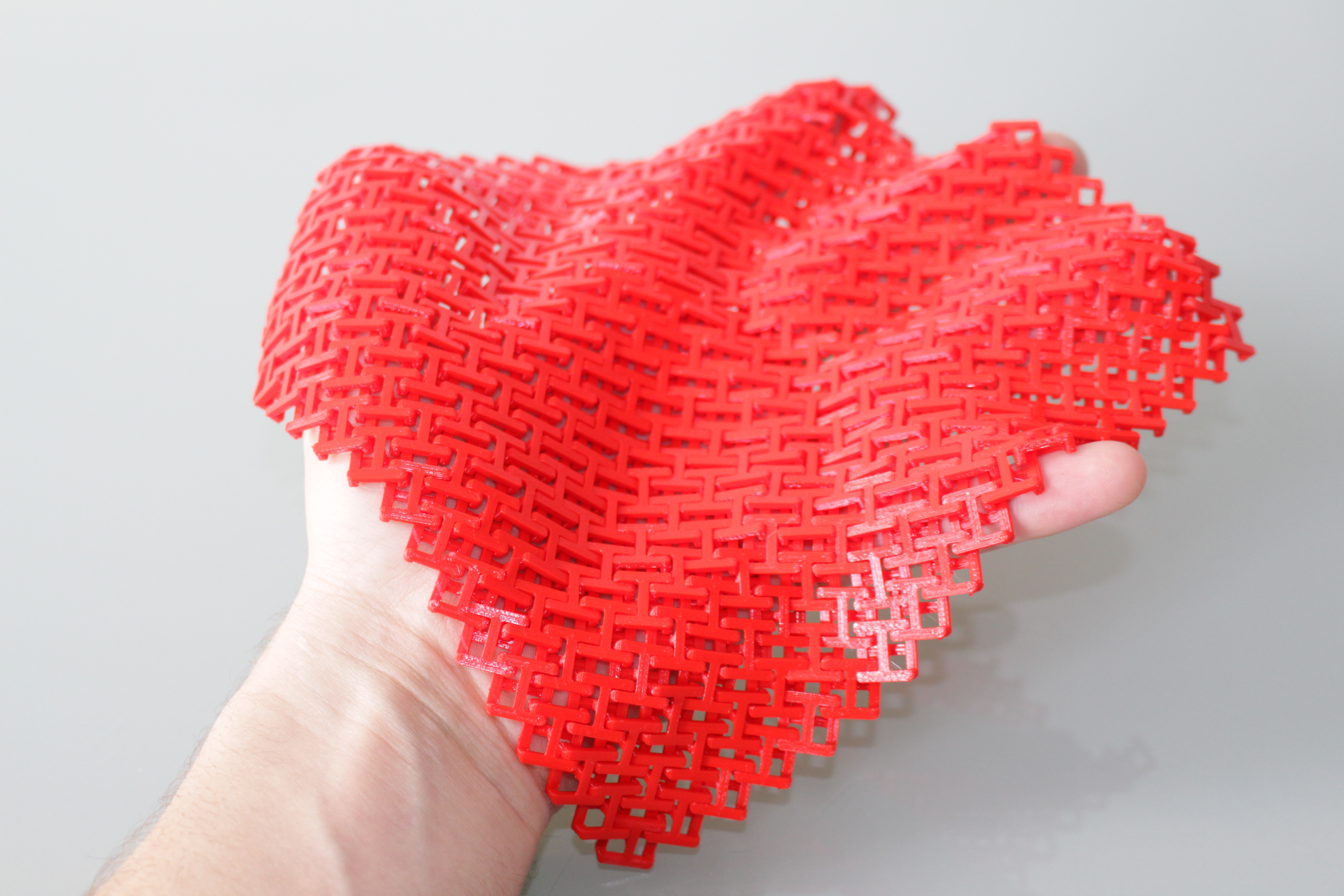

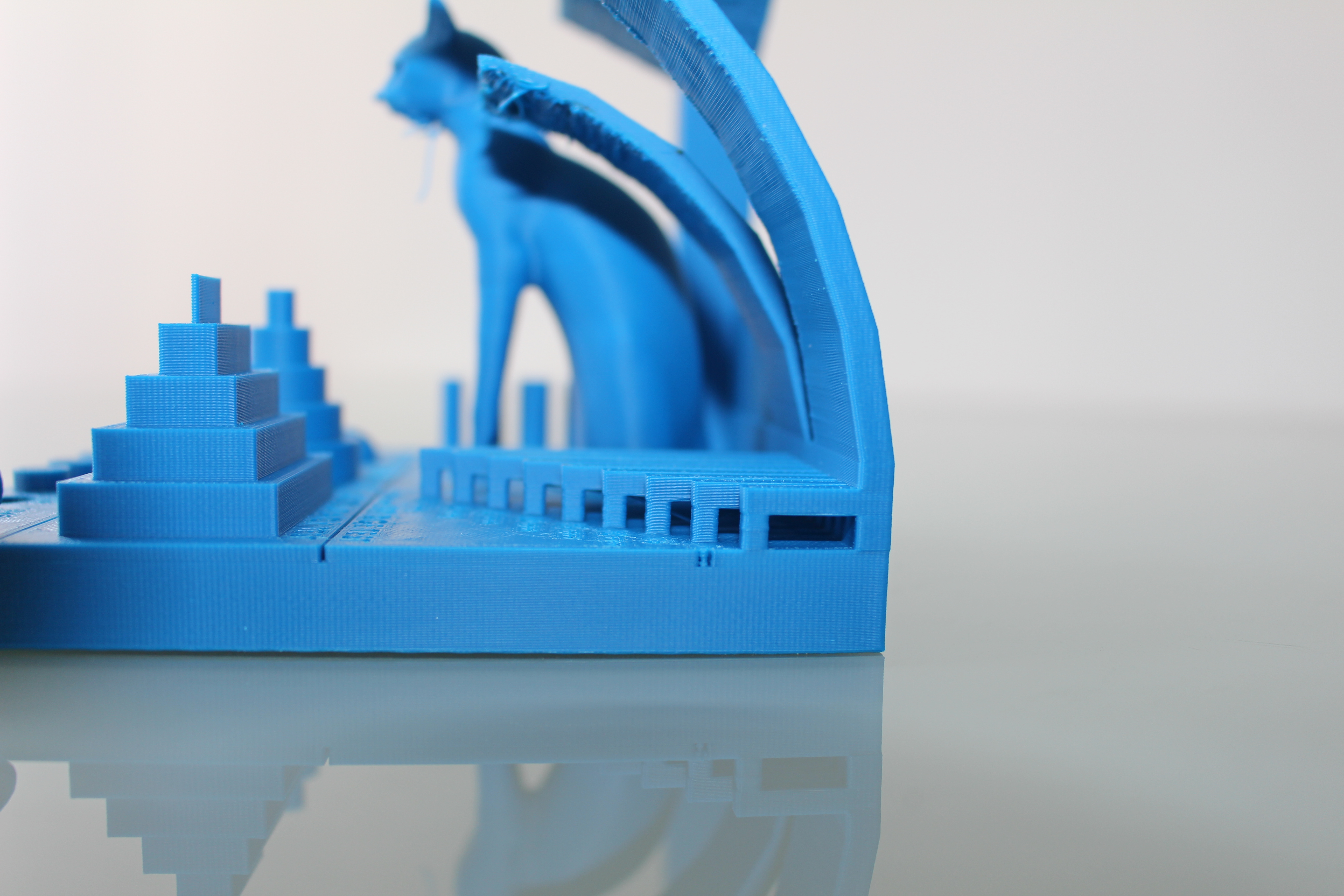

It’s time to put the Guider 2S through its paces to see if that “industrial-grade” tag has any substance to it. We kick things off with 3D Printing Industry’s own benchmarking model – a part designed to consolidate all of the basic print tests we usually conduct into one 14 hour print. In this case, we printed the model twice: once in ABS (blue) and once in PETG (red) for reliability.

Looking at the retraction test portion of the part, we get a really good understanding of the system’s extrusion capabilities. With lower quality extruders, the square-shaped array of spikes would have plenty of stringing between the individual elements as the extruders would be unable to hold back the molten thermoplastic in time for the hotend to move onto the next spike. This is quite clearly not the case with either of the benchmarking tests printed on the Guider 2S – the prints start and stop exactly where they’re supposed to, resulting in clean shafts and sharp points.

Moving onto the overhang portion of the benchmark, we see that the Guider 2S managed to print overhangs of up to 65°. Beyond this limit, artifacts and stringing begin to occur but considering the common limit of 50° for most FFF printers, we can say that this mighty FlashForge system passed with flying colors.

Finally, the bridging portion of the benchmarking part is designed to determine the degree to which the machine is able to print horizontally without any supports. Together with the overhang test, the bridging test gives us an indication as to whether or not the printhead features adequate cooling. In this case, the quality of the bridges remain excellent up to 25mm, after which the structures begin to curve and warp. Seeing as anything longer than 15mm is generally considered above average performance, we can class this as another major win for the Guider 2S and its 360° fan duct.

As is tradition here at 3D Printing Industry, we then went onto print a classical artistic piece on the system. This time round, we opted for a statue of Artemis and Iphigenia, two key players in Greek mythology.

As though it was forged by Hephaestus himself, our sculpture emerged with smooth curves and invisible layer lines, despite needing a filament change halfway through. The Guider 2S did a fantastic job of preserving the fine details and intricacies of the two figures in the model, although a few of the features on the accompanying deer failed to materialize. This is indeed a very difficult model for any FFF printer to fabricate due to the abundance of overhangs and interlocking geometries, but the Guider 2S held its own admirably.

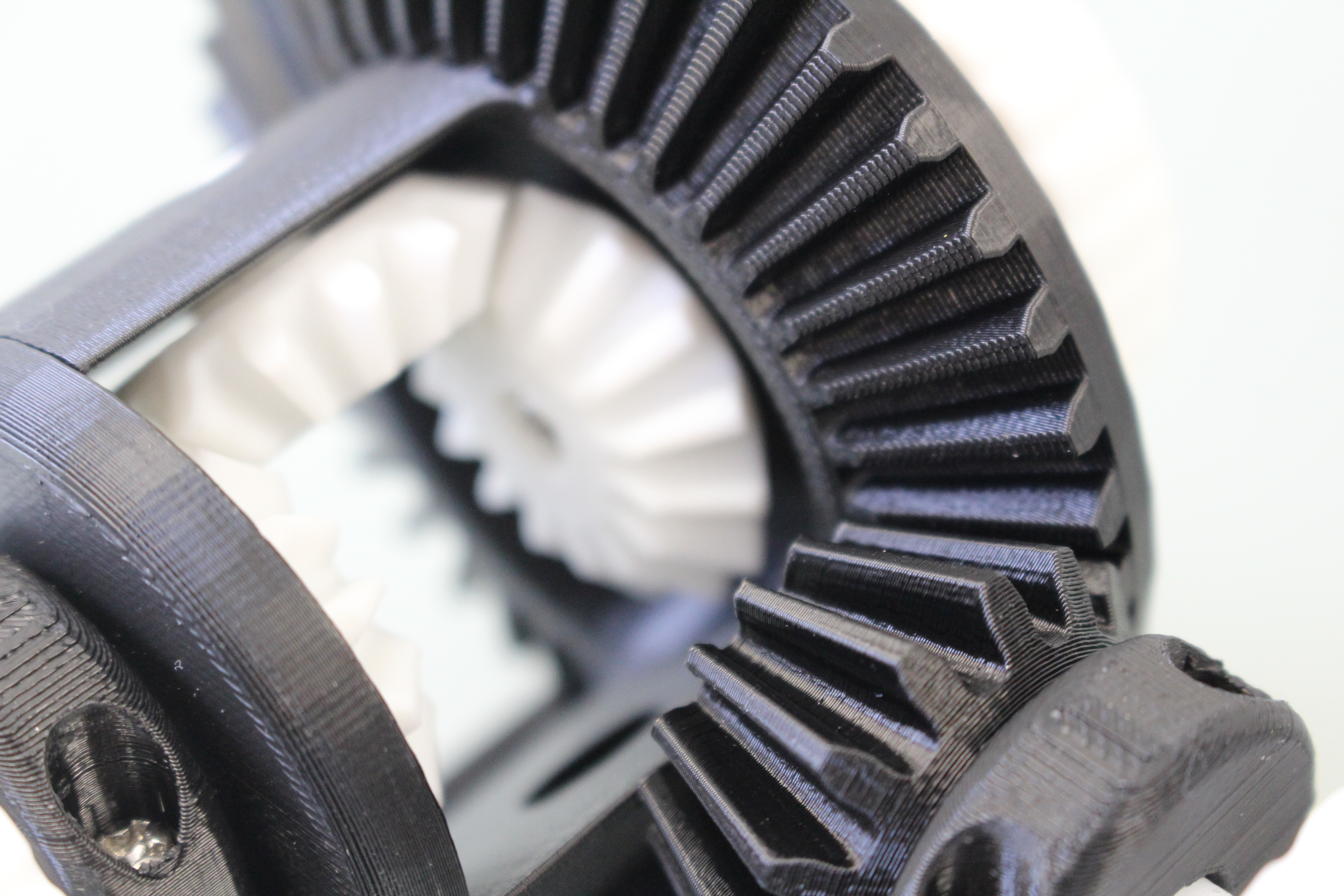

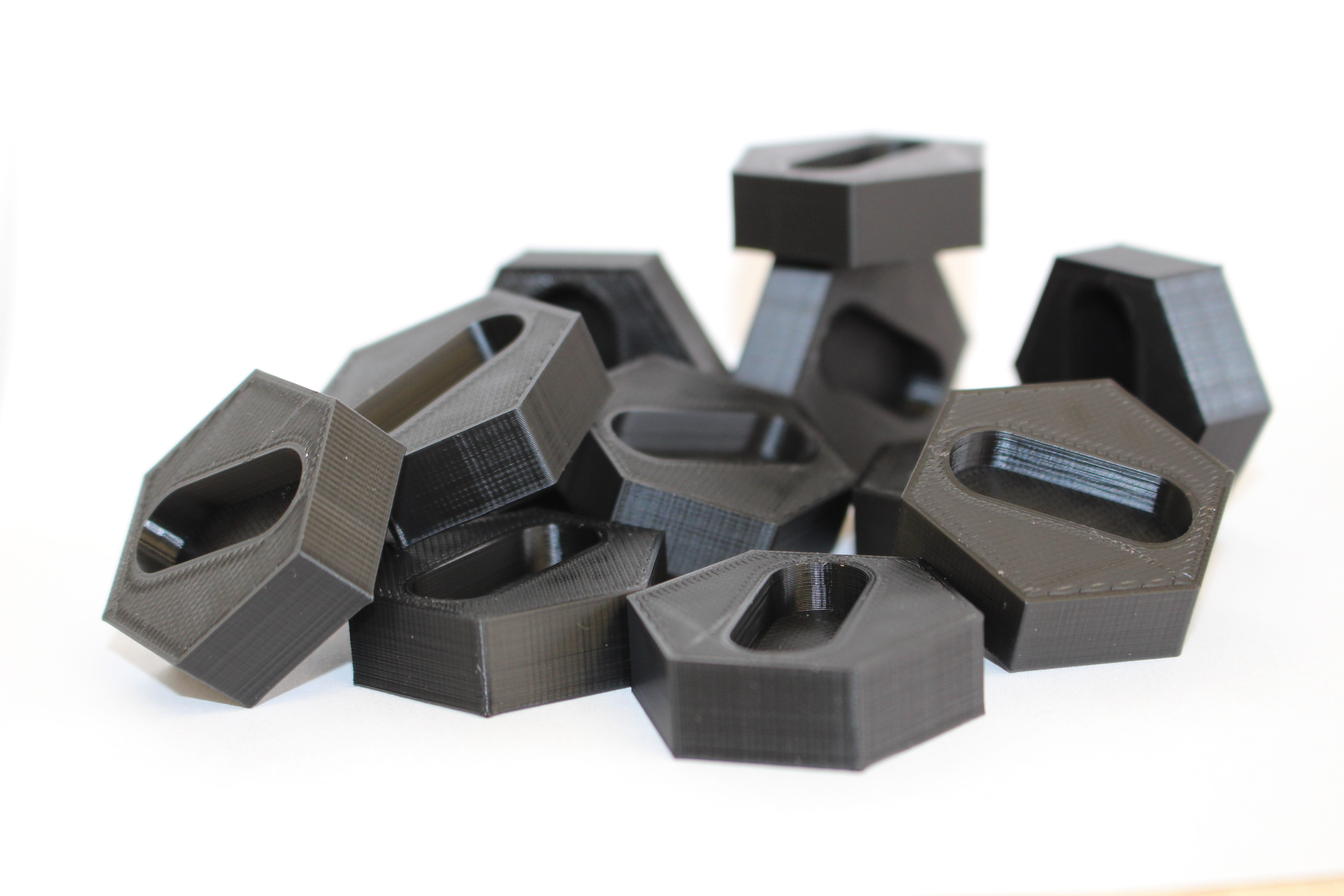

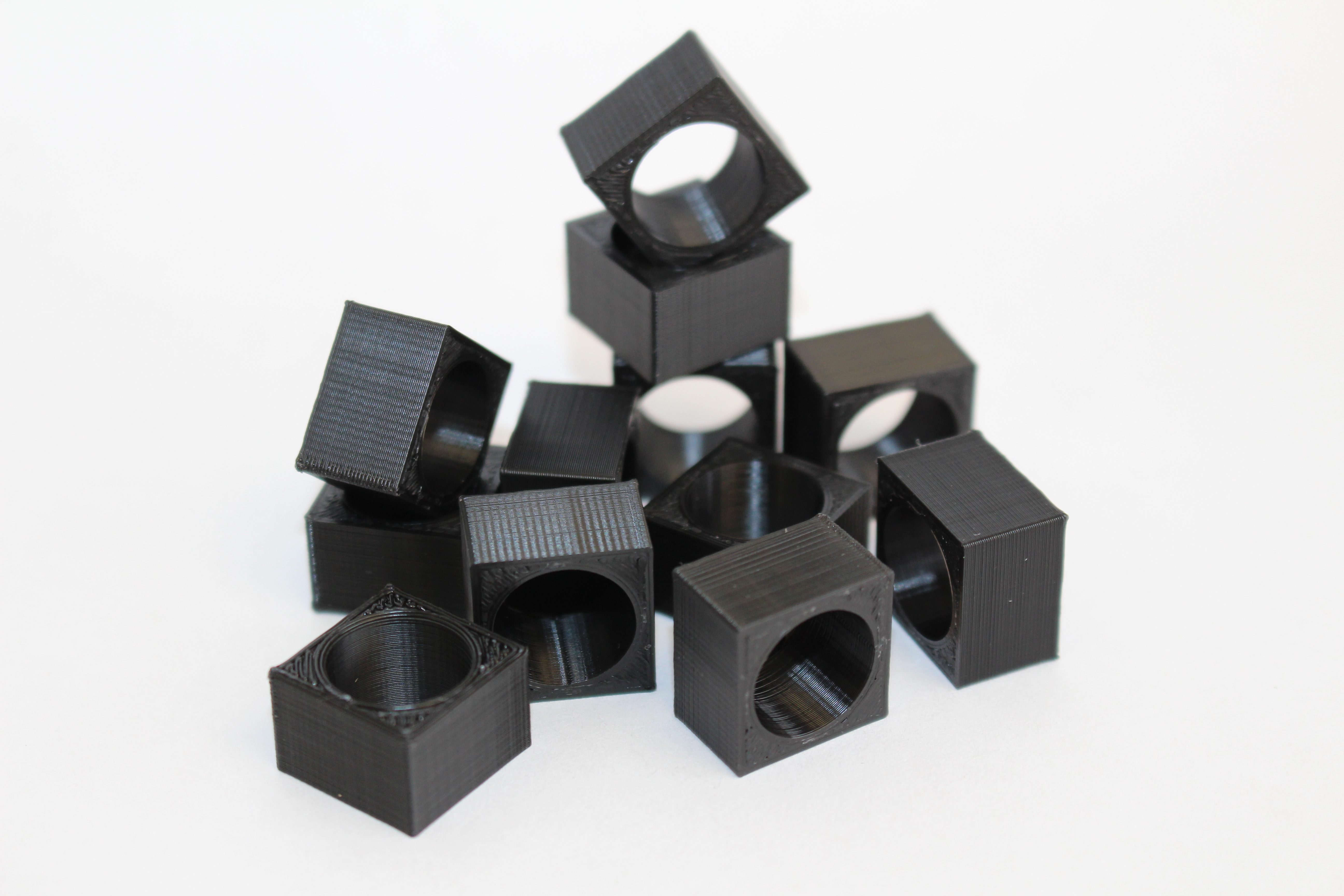

For the final test run, we decided to print a mechanical assembly – specifically, a differential gear system. This is one of our longest-standing and most reliable print tests as it is great for determining the dimensional precision of a printer. The differential gear system will only assemble with ease and operate with smoothness if all of the individual components maintain tight tolerances.

As expected, the FlashForge jumped its final hurdle without a hiccup. Each of the components had a high surface quality, resulting in minimal resistance in the assembly. The differential gears look and feel great, and can definitely be used in practice for a functional application.

The verdict

When the dust settles, we’re left with what can only be described as a FlashForge classic. The manufacturer has an almost perfect track record of quality machines, and the Guider 2S is no exception to this. This is how a quality-of-life model should be done – keep what works and add what’s missing. The addition of the camera, filament sensor, and HEPA filter makes the system a dream to operate, all wrapped up in that FlashForge robustness.

In terms of gripes with the printer, the few we have are minor and can be overlooked. The Z-axis driver is fairly slow and can be noisy, so be prepared to lose 30 seconds here and there. We also wish the print time estimates were a little closer to the actual print times (they were ~9% off) and we couldn’t find the configuration files necessary to use the machine with an open-source slicer like Cura. Regardless, FlashPrint soothes our concerns – the proprietary software is all you could ask for whether this is your first printer or your tenth.

At sub-$3000, the print quality is well worth the price point and the system as a whole is reliable. If 3D Printing Industry had a seal of approval, it would certainly be stamped on the FlashForge Guider 2S.

Buy the FlashForge Guider IIS here.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the FlashForge Guider IIS 3D printer. Photo via FlashForge.