The DOBOT Magician is a multifunctional robot arm built to be capable of 3D printing, laser engraving and pick and place. Marketed as an “all in one robot for education” the system is designed to introduce students to programming. At 3D Printing Industry, our engineering team recently tested the DOBOT Magician to see how suitable it is for these intended uses.

The key claims of the arm are: easy-interchangeable tools, multiple means of control, programmability, and suitability for the classroom, home, workshop or factory. Each of these claims are retained for perspective throughout this review.

Unboxing and assembly

Like the previously tested DOBOT MOOZ the Magician was securely packaged when it arrived, with all contents sectioned separately. Schematics on smaller boxes help the user identify components inside, and an enclosed guide makes unpacking easy taking only 5 minutes.

The manual included in the box was very brief – good for setting up first connections, and the main body of the guide is included in a further online document. Here, the team also noted that the main connection of the Magician robot arm were covered with flexible silicone lids, ensuring good dust protection, suited to use in a workshop environment.

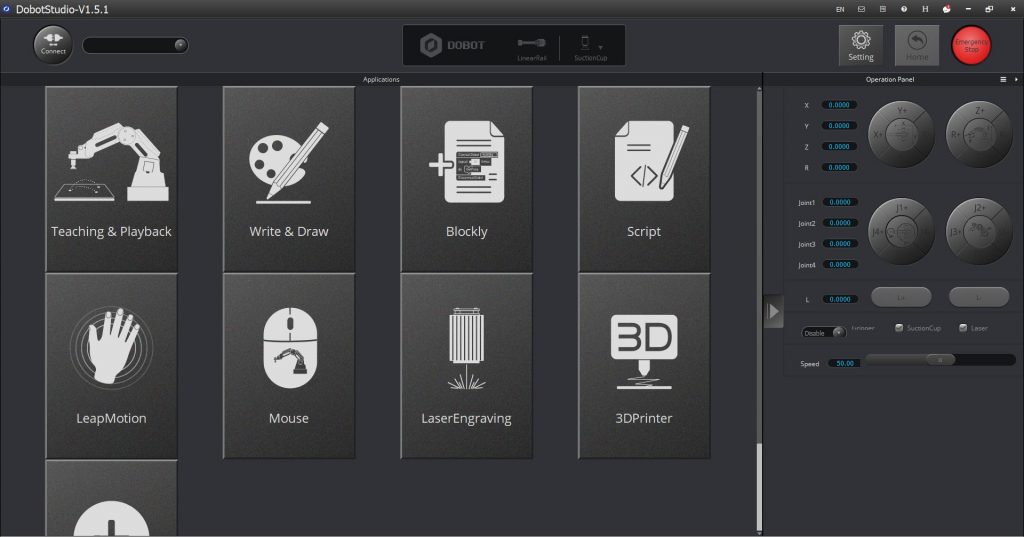

Power supply connection was simple, and labels attached to the wires made initial setup easy. For calibration, the team installed the recommended DobotStudio software. Navigating DobotStudio was reasonably user friendly and intuitive, and offers three different calibration modes: Base Calibration, Manual Levelling and Auto Levelling. In this instance, the Auto Levelling method worked well.

As initially claimed, it is easy to switch between the various tools available. Applying a filament holder and feeder for 3D printing was also intuitive, and each head/module is mounted using a screw.

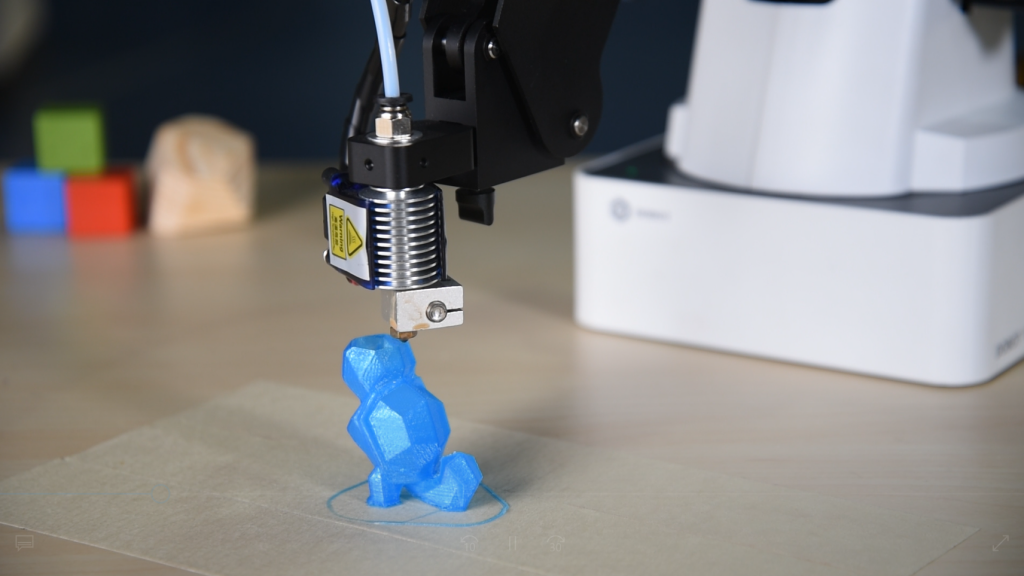

3D printing test on the DOBOT Magician

The DOBOT Magician claims a print size of 150 x 150 x 150 mm, layer resolution ranging between 100 – 200 μm, and an ability to use standard 1.75 mm PLA on a non-heated glass bed, a component also easily installed on the system. With the 3D Printer component selected in DobotStudio the software seamlessly switched to RepetierHost for printing.

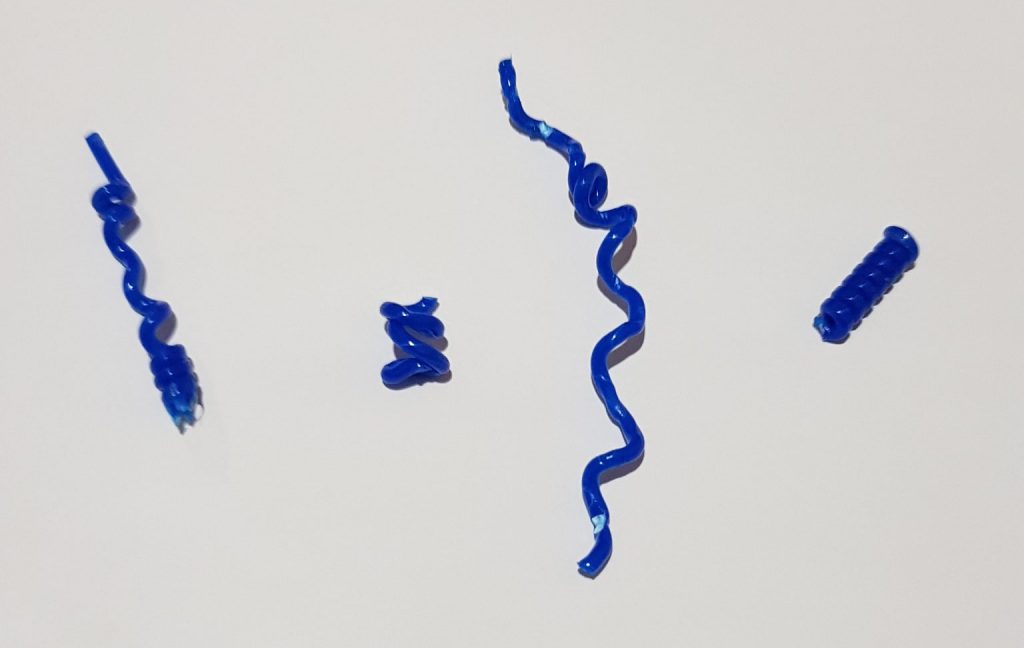

For this test, three different files were tried: a simple cup, a 3DBenchy, and a complex Great Wall of China model. Throughout each job, it was easy to remove the printhead when clogging occurred.

In these tests, the engineering team discovered that the Magician is more suited to 3D printing simple structures like the cup. However, the DOBOT Magician was not suitable for 3D printing more complex objects, due to the spanning required in these models. At a print speed of 1 mm/s the engineers succeeded in producing two sizes of the simple cup model, with some removable stringing on the inside of each one.

Writing, drawing and laser engraving

With writing and drawing modes for the DOBOT Magician the team were first impressed by the variety of tools available. A pen, gel pen, paint brush, and other writing implements could all be mounted to this gripper, highlighting the robot’s expressed purpose as an education tool. As in the 3D printing test, DobotStudio integration of the Write & Draw component was seamless. The interface gave a clear indication of the max writing envelope the Magician is capable of.

The claims made of the Writing and Drawing module is a repeatability position accuracy of ±0.2 mm. Here, the engineers tested a writing sample of “3D Printing Industry” with the Magician, and a simple drawing of a flower.

Both outputs were of a decent quality though repeatability did not match the degree of accuracy, but this could be improved by using thicker pens.

The Laser Engraving module of DobotStudio had a very similar layout to Write & Draw which made it easy to use. This tool worked best on engraving wood, but a slower writing speed would be required for engraving paper and leather.

The Pneumatic Gripper/Suction Cup

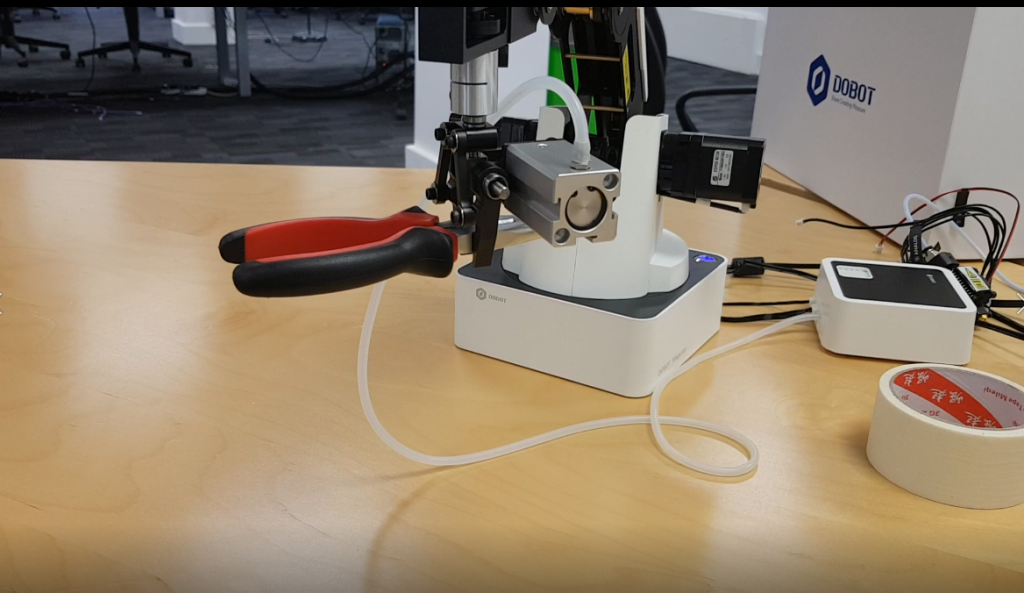

The pneumatic pump attachment for the DOBOT Magician can be used as suction cup for pick and place of objects, and as a gripper for moving objects for a programmed purpose.

As with all modules, the pneumatic pump is easy to mount. In the first test the cup was able to carefully lift, move and rotate two boxes, one stacked on top of the other, without dropping the unsupported box.

Secondly, the gripper made easy work of lifting, moving and rotating, a roll of tape, and then successfully lifted and leveller moved a pair of pliers, weighing around 200g, with no difficulties at all.

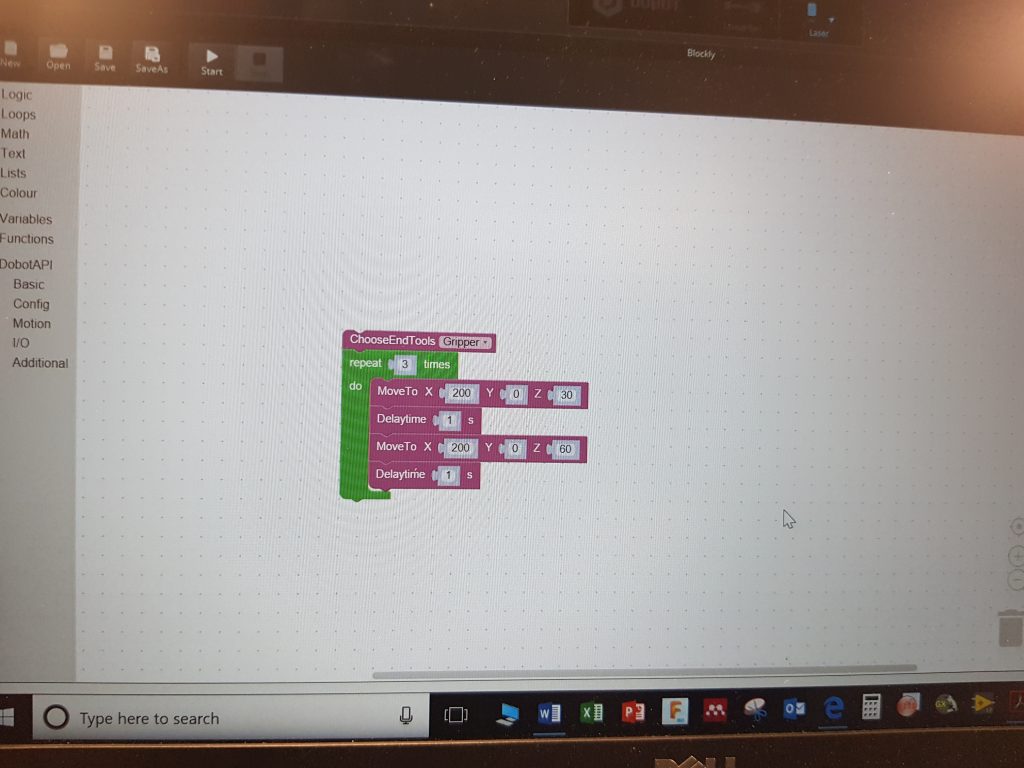

In a final test, the team put DobotStudio’s Blocky integration to the test. Blockly is a user-friendly, open source software developed by Google to make it easy to write programming languages. This feature of DobotStudio was very impressive and proved easy to learn. Using a sample pick and place program outline in the manual, the team created an operation for the DOBOT Magician enabling it to pick and place two stacked boxes from one spot to another specified location.

Connectivity

The wireless gamepad controller of the DOBOT Magician worked well, especially when used for controlling pneumatic pick and place. Even 10 m away from the system, it was still within range for full control.

The mouse control worked as expected, and the Magician followed its movements efficiently. Bluetooth control was access via a Dobot Magician App, however the module on the Magician had some difficulties picking up the Bluetooth signal from the phone.

Final verdict

In conclusion, the engineers summarized that the DOBOT Magician has much to offer. According to our team “It has taken a significantly novel step towards educating the next generation in an unprecedented effective way, by enabling itself to be controlled through simple tailored programs that can be coded by young programmers.”

As stated, tools were easy to mount and remove, and DobotStudio gave a lot of scope for educational use. Programmability was a key strength of the system, and its compact size is suited to placement in the classroom, home or workshop.

For more exclusive news and reviews subscribe to the 3D Printing Industry newsletter, find us on Facebook and like us on Twitter. Looking for jobs in engineering? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

Featured image shows the DOBOT Magician robot arm. Photo via DOBOT