An affiliate of “National Additive Manufacturing Innovation Institute” America Makes, the latest edition of Additive Manufacturing journal is scheduled for publication in December 2018. Now in volume 24, this edition will feature over 50 research articles from institutions all around the globe including the University of Twente, Tokyo University of Science and the University of Milan.

At 3D Printing Industry, we examine some of the upcoming features of the journal: microscale 3D printed gold; supersonic electronics; and carbon fiber reinforcements for the Japan Aerospace Exploration Agency (JAXA).

University of Twente strikes gold

At the University of Twente (UT), the Netherlands, researchers have developed droplet-based approach for 3D printing microscopic structures in gold.

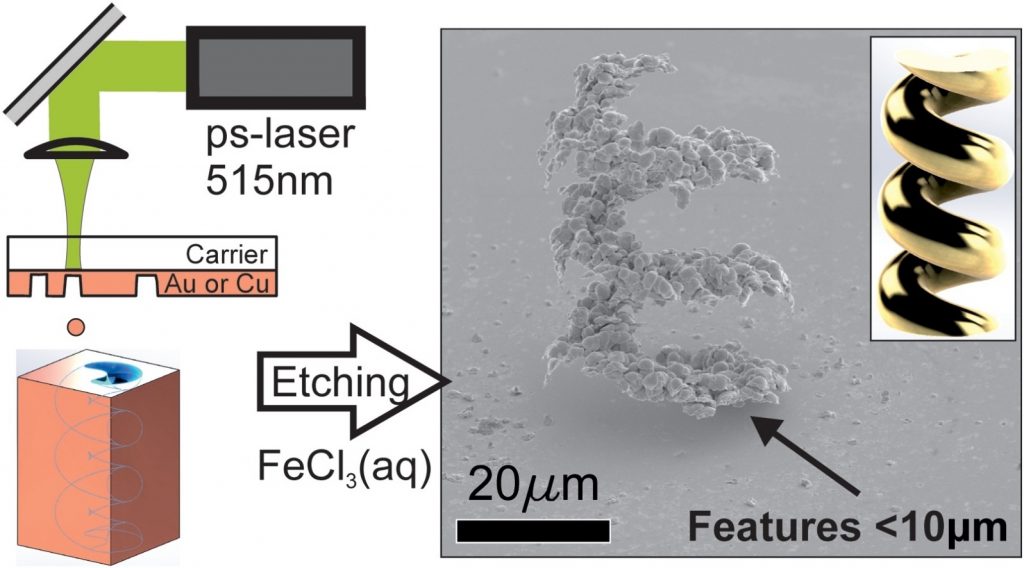

Termed laser-induced forward transfer, or LIFT, this method creates structures with “unprecedented feature sizes of smaller than 10 μm”, unlocking a plethora of applications in the biomedical sphere.

A free-standing 3D printed spiral produced in the experimentation can be seen below.

The full paper of this research, “Printing of Complex Free-standing Microstructures via Laser-induced Forward Transfer (LIFT) of Pure Metal Films,” can be accessed online here. It is co-authored by Matthias Feinaeugle, Ralph Pohl, Ton Bor, Tom Vaneker and Gert-willem Römer.

Previous, 3D printing research at UT includes a rapid bioprinting technique termed “in-air microfluidics” as previously featured on 3D Printing Industry.

Multimaterial 3D printed electronics from Milan

Adding to a growing body of integrated additive manufacturing approaches for electronics, a team at the Università degli Studi di Milano (University of Milan) have demonstrated a multimaterial approach for creating conductive devices.

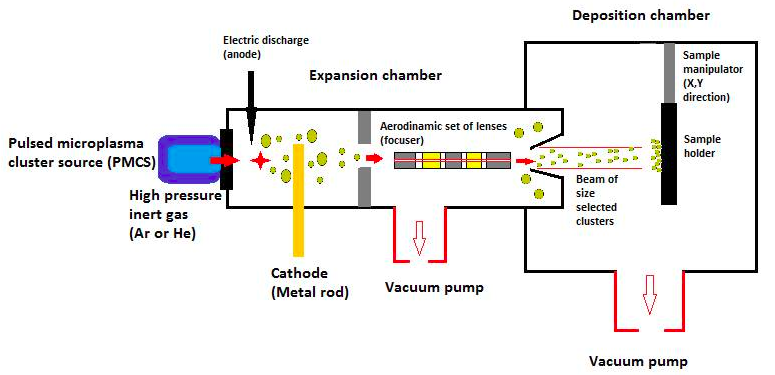

The method combines typical FFF material extrusion with supersonic cluster beam deposition (SCBD) – a technique commonly used for spraying thin films of material.

According to the abstract, “A multi-step fabrication procedure alternating FFF and SCBD was developed and optimized allowing the fabrication of conductive 3D oblique paths, bridging vias, and sockets for standard electronic components fitting.” A light sensor was produced as a demonstration, streamlining the structure of standard planar electronics.

“Embedding electronics in 3D printed structures by combining fused filament fabrication and supersonic cluster beam deposition” can be found here. The paper is co-authored by Andrea Bellacicca, Tommaso Santaniello and Paolo Milani.

Curved carbon fibers for aerospace

And the Tokyo University of Science in Japan has led a research initiative into 3D printed carbon fiber composites for the Japan Aerospace Exploration Agency (JAXA).

The purpose of the study was to understand the effect of set curvatures and fiber bundle sizes on the quality of a circular 3D printed part.

Through experimentation, the team were able to devise a map for each printed material that could be used to predict “printable” and “unprintable” circle radii, leading to further investigation of the strength of the components.

“Effects of Set Curvature and Fiber Bundle Size on the Printed Radius of Curvature by a Continuous Carbon Fiber Composite 3D Printer” is published online here. It is co-authored by Ryosuke Matsuzaki, Taishi Nakamura, Kentaro Sugiyama, Masahito Ueda. Akira Todoroki, Yoshiyasu Hirano and Yusuke Yamagata.

Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook for regular additive manufacturing research updates. Seeking a new development opportunity? Join 3D Printing Jobs now or advertise a vacancy to reach our specialized readership.

Featured image shows a 3D printed gold spiral from the University of Twente research. Image via Additive Manufacturing journal.