In this article looking at the future of 3D printing, Karen Dubbin discusses the emerging 3D bioprinting sector.

3D bioprinting company, Aether recently appointed Karen Dubbin as science director. With degrees from MIT and Stanford in Materials Science and Engineering Dubbin is interested in biomaterials for regenerative medicine.

Her work at Ali Khademhosseini’s lab in the Harvard/MIT HST program looked at developing small tissue mimics for high throughput drug testing using thermo responsive molds. During her time with Sarah Heilshorn’s lab at Stanford, Dubbin worked on their injectable hydrogels for both cell transplantation and bioprinting applications.

As science director at Aether, Dubbin is currently developing a line of bio-inks, which the company expects to be available late 2017.

The future of 3D printing by Karen Dubbin, Science Director at Aether

The market for 3D printing of thermoplastics, thermosets, and metals has grown rapidly over the past 10 years, making 3D printing more accessible to large companies, academic labs, and individuals. The development of desktop printers and decrease in the cost of hardware and consumables have led to an increase in accessibility for the technology.

Many K-12 students now have access to 3D printers in their school or local libraries today, a concept that seems incredible for those of us who were in school even 10 years prior. With this increase in technology accessibility, the barrier to innovation is lowered. We hear stories of students printing their own braces, making prosthetic hands, and drones for cargo delivery – new applications are developed every day.

Over the next five years the increased accessibility of 3D printing in these fields will be essential for a surge in innovation, with the potential to transform major industries ranging from food to medicine.

Translating 3D Printing to Medicine

Imagine living in a world where scientists could design replacement tissues specifically for your injury or illness.

While currently doctors rely on strategies such as organ transplants and autografts to replace damaged tissues, researchers have been interested in using 3D printing to develop engineered tissues for implantation or drug testing for years.

Tissues and organs consist of complex arrangements of different cell types as well as intricate 3D architectures such as vasculature. 3D printing is a promising technology that can potentially be used to mimic biology due to the part complexity and reproducibility it can yield compared to other manufacturing techniques.

These capabilities have the potential to revolutionize tissue engineering by harnessing technologies developed for 3D printing of polymers, metals, or ceramics to precisely pattern cells to develop complex tissues and organs. This is done either by encapsulating live cells within a biomaterial scaffold for printing, or printing scaffolds that can be embedded with cells to create “living” materials.

Challenges facing 3D bioprinting

The successful translation of this technology from printing inorganic materials to living cells will require solving a number of challenges, including maintaining cell viability over long periods of time.

At this time we can’t predict if or when we will overcome these difficult challenges, but if we do, the benefits to human health could potentially be unprecedented. Currently, 22 people in the U.S. die each day waiting for an organ transplant.

With the ability to manufacture replacement organs for transplant, this number could be greatly reduced- vastly improving patient outcomes and quality of life. Furthermore, bioprinting is poised to transform the drug development market using 3D printed tissues for drug testing and pre-clinical trials.

The use of these artificial tissues could reduce the time and money spent on drug discovery which could lead to faster development and lower drug costs.

Bio-ink Development

In order to improve the accessibility and performance of bioprinting, materials development for cell-compatible printing will become increasingly important in the next 5 years.

Hydrogels are the biomaterial typically used for tissue engineering applications due to their similarity to the native cell environment in the body. For this reason, hydrogels are promising bio-inks for cell-based 3D printing.

Printing of polymers, ceramics, and metals usually requires large changes in temperatures due to high melt temperatures. Since cells are not able to go through such large temperature changes, different curing strategies must be employed.

Typically, bioprinting occurs by extruding inks with cells through a syringe and curing the printed construct with limited photo/ionic crosslinking thermo-gelation, or some combination thereof.

Inkjet, microvalve, and laser-induced forward transfer printing have also been explored, which each require unique materials development. In every case, the ability of the cell-filled ink to protect cells during printing is essential for maintaining viability and preventing membrane damage.

By improving cell viability and function, we move closer to developing functional tissues and organs to save lives, improve drug discovery, and other unexplored uses for engineered tissues.

Improving Bioprinting Accessibility

Less than a decade ago, the first commercially available bioprinters cost hundreds of thousands of dollars, a price that was prohibitory to many researchers interested in 3D printing for medicine.

Similar to desktop FDM or SLA/DLP 3D printers, desktop bioprinters have recently been developed at a lower price point, increasing accessibility to researchers in academia and industry.

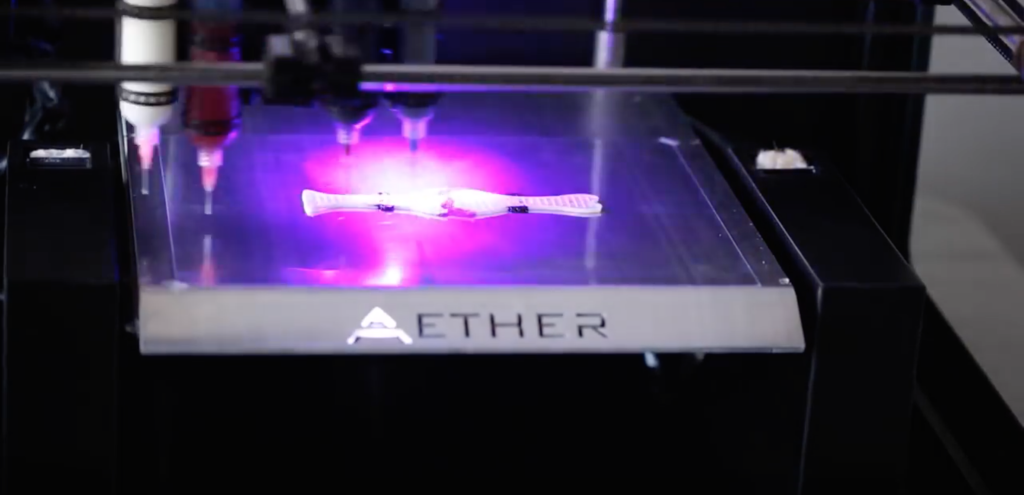

Aether aims to make the field of bioprinting more accessible by providing advanced 3D bioprinting technology at a very low cost. The Aether 1 printer contains a range of fabrication possibilities such as extrusion and microvalve injection technology to allow greater flexibility in material choice for printing 3D tissue constructs.

Additionally the Aether 1 contains more print heads than similarly priced bioprinters, allowing for increased complexity through printing.

This increases innovation potential by allowing users to make the most of different printing technologies together in ways that were not previously possible.

With Aether’s entrance into the bio-ink market, we aim to provide cell compatible inks at low cost to allow researchers to innovate in the 3D printing for regenerative medicine field. We hope lowering the barrier to entry for bioprinting through collaborations with industry and academic partners can help pave the way for future advancements in fields ranging from tissue engineering to drug development- advancements that can revolutionize human health.

More information about Aether is available here.

This is an article in our series looking at the future of 3D printing. To date more than 60 3D printing and additive manufacturing experts have given us their perspective on the trends, challenges and opportunities in the 3D printing industry. If you’d like to join them, contact us here.

For more insights subscribe to our free newsletter and follow our active social media accounts.