Kai von Petersdorff-Campen, a doctoral student in the Department of Mechanical and Process Engineering at ETH Zürich, Switzerland, has developed an additive manufacturing technique to manufacture objects containing magnets.

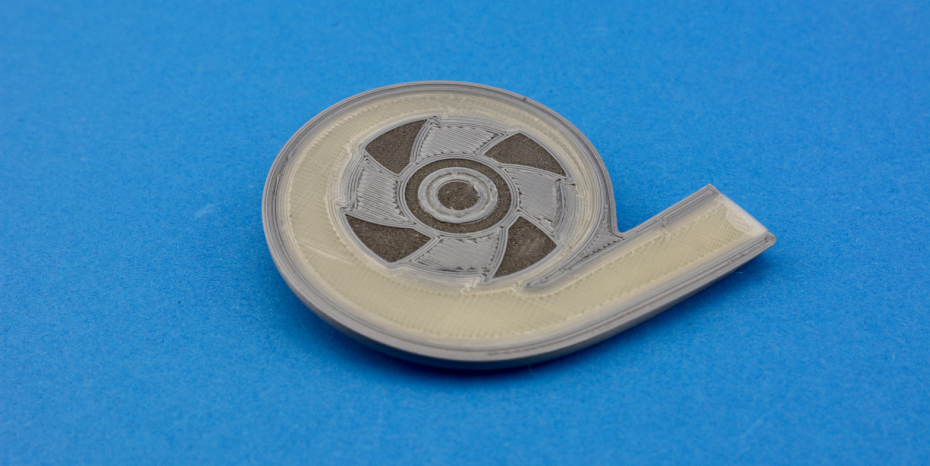

Petersdorff-Campen demonstrated his method, called “Embedded magnet printing,” by 3D printing an artificial heart pump prototype. The doctoral student adds, “My goal was not to make a good heart pump, but to demonstrate the principle of how it can be produced in a single step.”

Embedded magnet printing

According to Petersdorff-Campen, research in 3D printing with magnets is still in its infancy. As part of the Zurich Heart project, the researcher decided to test his method by creating an artificial heart pump, which is geometrically complex and magnetic. Thus, embedded magnet printing was created to confirm the ability to print magnets directly into the plastic.

Within the process, a magnetic powder and plastic are mixed and formed into filament. Using FDM technology, these filaments are printed as the nozzle automatically outputs the computer-generated form, with its various components. The printed parts are then magnetized in an external field.

The plastic heart pump prototype took a total of 15 hours to print.

Developing magnetic filament

One of the main challenges during Petersdorff-Campen’s experimentation arose in the development of the filaments. The more magnetic powder that is added to the granulate mix, the stronger the magnet, however, this results in a more brittle end product.

“We tested various plastics and mixes until the filaments were flexible enough for printing but still had enough magnetic force,” added Petersdorff-Campen. “Some people are already asking where they can order the material. That was not my focus, I simply wanted to show the principle.”

Petersdorff-Campen’s embedded magnet printing process was also awarded the first prize for prototyping from the American Society for Artificial Internal Organs (ASAIO). Despite the positive reception, embedded magnet printing has faced some criticism as others have deemed it to be unsuitable for the production of medical devices, due to the various approval processes.

“There is still a lot to improve in terms of material and processing; I wouldn’t want to have such a device implanted,” stated Petersdorff-Campen.

This method is said to have the potential for manufacturing electric motors, used within technical household devices, computer hard drives, loudspeakers, and microwaves.

3D printing and magnetics

Earlier this year, a team of researchers at Massachusetts Institute of Technology (MIT) created magnetic, 3D printed creatures, from soft materials, capable of dynamic movement. Prior to this, an international academic paper, with contributions from the Chinese University of Hong Kong, introduced an additive manufacturing process that embeds magnetic particles into polymer with designed patterns for soft robotics.

Petersdorff-Campen. research paper, titled “3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump,” is co-authored by Kai von Petersdorff-Campen, Yannick Hauswirth, Julia Carpenter, Andreas Hagmann, Stefan Boës, Marianne Schmid Daners, Dirk Penner, and Mirko Meboldt.

Catch up with the latest in additive manufacturing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the design for the heart pump prototype. Photo via Kai von Petersdorff-Campen/ETH Zurich.