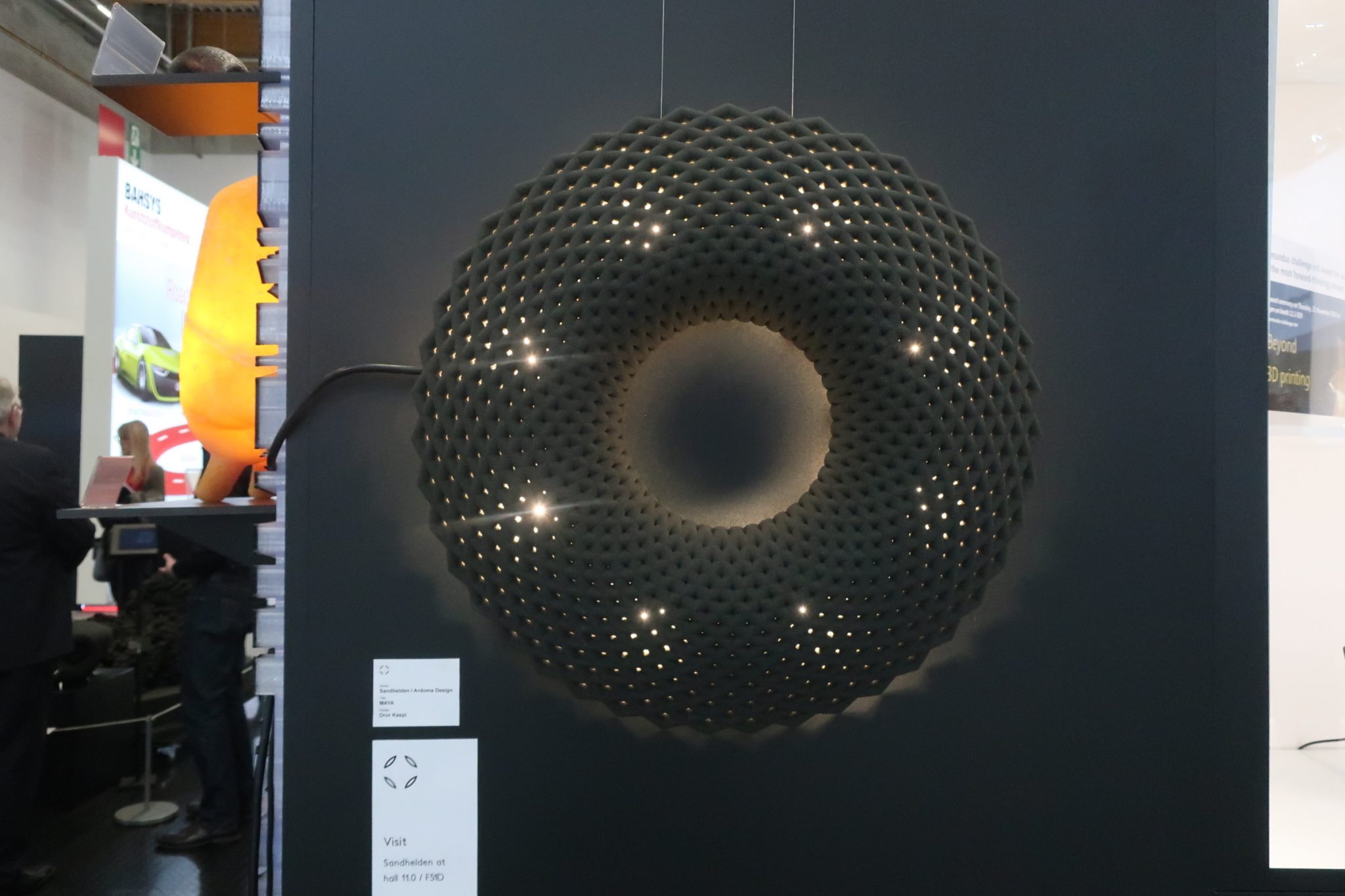

During last month’s Formnext show in Frankfurt, the seventh edition of the purmundus 3D printing design award took place.

Based on this year’s theme of “Beyond 3D Printing”, a total of 38 finalists from 18 different countries were whittled down to three winners by an international jury of professionals and supported by 3D Printing Industry.

The top prize was taken by the 3D printed Stealth Key from Urban Alps, followed by 4D printed “Hydrophytes”, designed by Nicole Hone of Victoria University of Wellington. In third place was Dr. Paul Schüler and Andreas Krüger from CellCore GmbH for their monolithic combustion chamber of a rocket engine. These 3D printed products were deemed to showcase the most benefits in terms of use, economy, aesthetics, design, and innovation out of the 38 entries.

Previous winners of the purmundus challenge

Held by German rapid prototyping company Cirp GmbH, the annual purmundus challenge invites entries from around the world to participate in a theme-based 3D printing design contest. The contest is open to the international design and 3D printing community, which includes individual designers, institutions, and companies.

Last year’s theme for the 2018 purmundus challenge centered on “3D printing gears up our future.” This theme explored designs for future living, and what role 3D printing will play in that context. First prize went to Ricardo Simian of 3D Music Instruments. Simian submitted an SLS printed cornetti, a Renaissance and Baroque era wind instrument. The adidas Grit Shoe, made by Aarish Netarwala, an industrial designer, was the winner of the second prize. And in third place was Dr. Christoph Kiener and Manuel Biedermann from Siemens AG, who designed a bionic fuel burner.

3D printed Stealth Key takes top prize

For this year’s edition, the “Beyond 3D printing” theme asked designers to showcase ground-breaking 3D and 4D printing ideas in the field of product design that “can influence and enter our everyday life in a useful way.”

A total of €30,000 in prize money was divided amongst the winning three applicants. In addition to the first three places, there were also awards for the following categories: “special mention”, “innovation prize”, “people’s choice” and “simulation-driven design by Altair.”

Dr. Alejandro Ojeda, co-founder of UrbanAlps, was awarded the top prize for the Stealth Key thanks to its innovative use of metal 3D printing to offer a maximum security solution. It is a fully customized mechanical key which has a cylindrical covering hiding the unlock code under robust, narrow projections. This means that the bittings (engaging the unlocking mechanism) of the key cannot be photographed or scanned.

Nicole Hone’s 4D printed hydrophytes was awarded second place thanks to its innovative approach to organic movement design. Hone created a set of five futuristic aquatic plants using multi-material 4D printing. The added dimension of time in 4D printing means the plants are able to react to physical stimulus, either contracting or blossoming depending on the situation.

Coming in at third was Dr. Paul Schüler and Andreas Krüger’s combustion chamber. The piece featured a functionally optimized lattice structure integrated within the chamber wall, which impressed the judges as it provided the necessary stability required, as well as offering cooling possibilities through efficient execution.

Voted for by Formnext visitors, the audience award went to Byron Blakey-Milner from Nelson Mandela University for his 3D printed mountain bike frame. Andreas Henneberg from Diehl Aviation was given the special mention for the 3D printed interior aircraft curtain comfort header, whereas the simulation driven design award was given to Gabriel Boutin from KUPOL for his personalized 3D printed motorcycle helmet. Finally, the innovation prize was awarded to the 3D printed miniaturized endoscope, designed by Andrea Toulouse from the University of Stuttgart.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 2019 purmundus challenge winners. Photo via purmundus challenge.