Diehl Aviation, an aerospace manufacturer specializing in cabin and avionics, has worked with international aerospace company Airbus to develop a 3D printed Curtain Comfort Header to be installed on Airbus’ A350 XWB jet airliner.

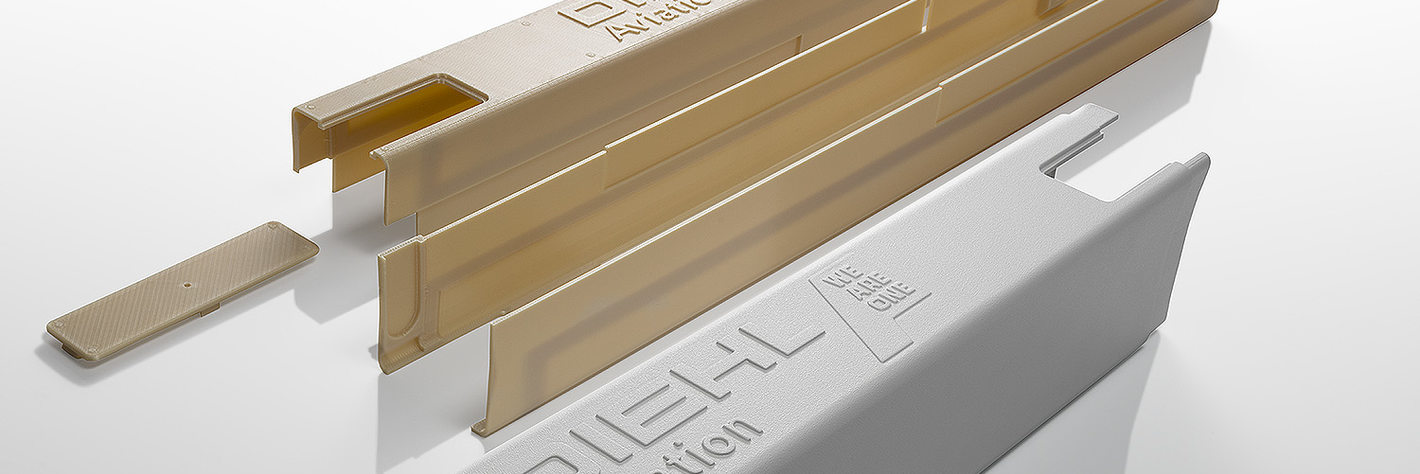

Made using 3D printing FDM technology, it is reportedly the largest 3D printed part to be produced for passenger aircrafts, and will be implemented first by the Qatar Airways airline company.

The 3D printed Curtain Comfort Header will be used to separate different classes on-board the aircraft, and took 12 months to progress from initial improved concept to EASA aircraft certification and delivery. Diehl Aviation is currently showcasing the 3D printed part at the Aircraft Interiors Expo 2019 in Hamburg, Germany.

Enabling customizable aircraft part manufacturing

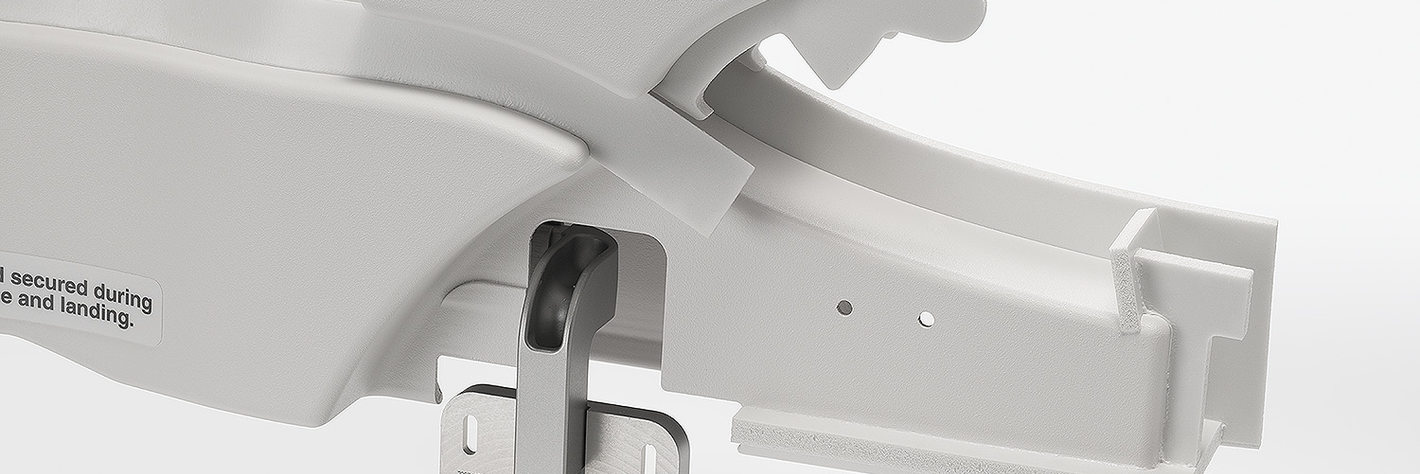

The 3D printed Curtain Comfort Header is designed to be applied to the curtain rail; a complex enclosure that helps to divide classes within the cabin. Measuring up to 1140 x 720 x 240 mm, the module comprises of 12 3D printed component parts that are attached together upon completion. The production of such parts simplified the tooling process for Diehl Aviation when compared to the traditional manufacturing process for the Curtain Comfort Header.

The modules are usually formed from numerous layers of laminated fiberglass, which required individual and complex aluminum tools for each layer. These tools are now made dispensable with 3D printing. Furthermore, the use of 3D printing also eases the customizability of the module, where incorporating further functions like emergency escape route signage and retaining clips was a difficult task with the laminated fiberglass method.

Customization of the Curtain Comfort Header also presents a benefit for the airline implementing the 3D printed part as well, as it can allow retrofit solutions to improve the passenger experience. Additionally, airlines will benefit from shorter production processes and lead time reduction using 3D printing, allowing for faster turnaround times.

Maintenance of the aircraft is made more manageable for the airline too, with 3D printed parts easily removable for repairs or replacement. With the present advantages for both Diehl Aviation and its customers, the company has opted to produce the Curtain Comfort Header for the A350 XWB aircraft exclusively with 3D printing.

Passenger aircrafts are taking off with 3D printing

Diehl Aviation is not alone in recognizing the benefits of incorporating 3D printed parts in the manufacturing of passenger aircrafts. In fact, Airbus has already integrated over 1000 3D printed parts on the Airbus A350 XWB and has also standardized the use of ULTEM 9085 3D printing material for use in the aircraft.

Finnish airline Finnair has also followed suit, partnering with Belgium 3D printing service provider Materialise to manufacture cabin spacer panels using 3D printing, allowing the company to save money and reducing service downtime.

Moreover, Air New Zealand, the flag carrier airline of New Zealand, has also incorporated 3D printed metal parts in the manufacturing of its aircrafts, in partnership with Zenith Tecnica, an Auckland-based 3D titanium printing company.

You can now cast your vote for the 2019 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed Curtain Comfort Header. Photo via Diehl Aviation.