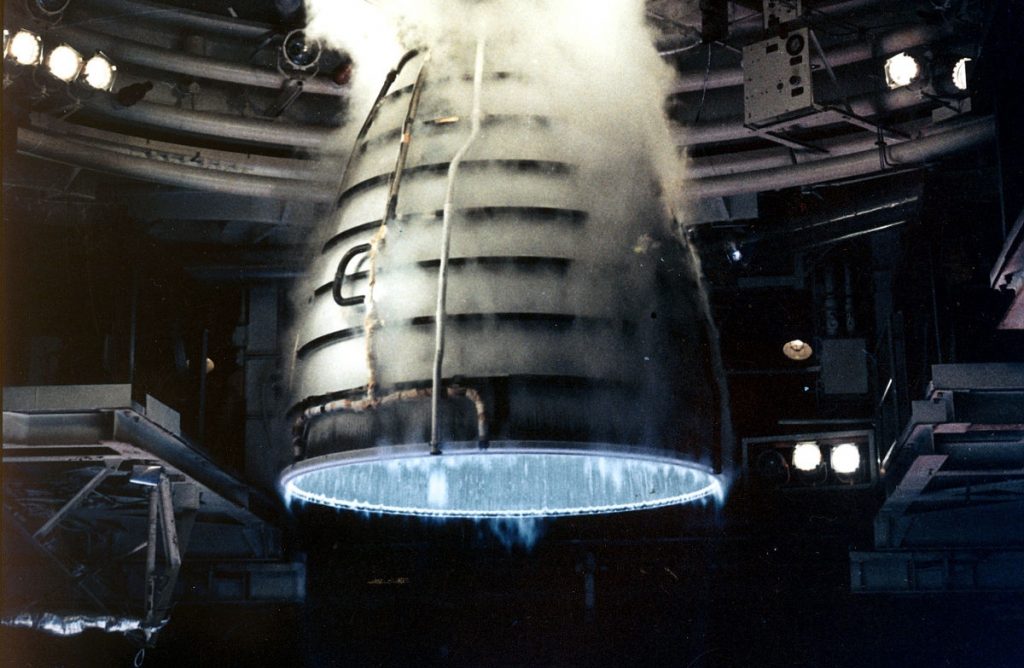

The National Center for Additive Manufacturing Excellence (NCAME) at Auburn University, Alabama, has been awarded a $5.2 million contract from NASA. Under this contract, the NCAME will apply its expertise to help improve the performance of liquid rocket engines, like the RS-25 Space Shuttle main engine (SSME).

Christopher B. Roberts, dean of the Samuel Ginn College of Engineering, home to the NCAME, comments:

“This new collaboration between NASA and our additive manufacturing researchers will play a major role in developing advanced rocket engines that will drive long-duration spaceflight, helping our nation achieve its bold vision for the future of space exploration.”

International additive manufacturing excellence in Alabama

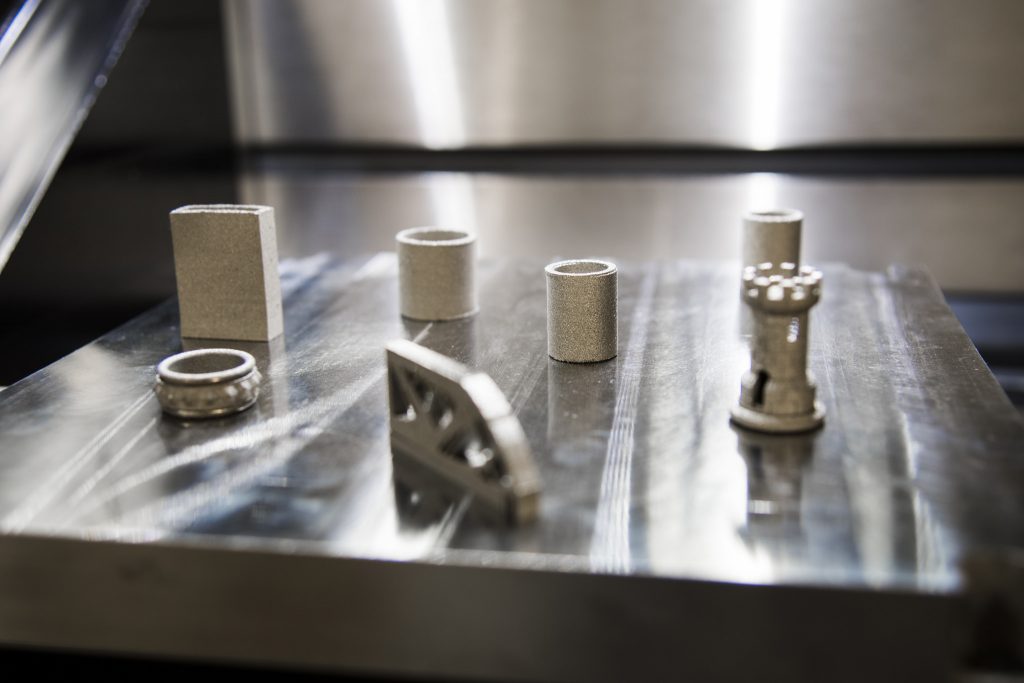

Founded in 2017, in collaboration with NASA, the NCAME is a public-private partnership between Auburn academics and over more than 70 industry, governmental and research partners. Focusing on areas of immediate importance to the wider manufacturing and standardization industry, NCAME conducts research across several valuable areas of interest, namely:

– 3D design

– New materials development

– Process monitoring

– Post-processing

– Microstructural characterizations

– Material properties

– Fatigue, fracture mechanics and failure analysis

– Qualification/certification, and,

– Non-destructive evaluation (NDE)

In 2018, the NCAME became a founding member of ASTM International’s Additive Manufacturing Center of Excellence program, creating strong ties between leading proponents in AM across the world.

On a national level, Auburn University hopes that this latest NASA contract will help drive additive manufacturing interest to the region. Mike Ogles, director of NASA programs in the Samuel Ginn College of Engineering, comments, “This contract is a giant leap towards making Alabama the ‘go to state’ for additive manufacturing.”

“We look forward to growing our partnership with NASA, industry and academia as we support the development of our nation’s next rocket engines.”

NASA Rapid Analysis and Manufacturing Propulsion Technology

The new $5.2 million contract from NASA will see the NCAME working on the Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) Project for the next three years.

Concept diagrams of the RAMPT-made trust chamber depict a multi-metallic component, with a freeform nozzle made using blown powder deposition. The combustion chamber within this engine is made from a copper alloy. In the assembly it is seamlessly fused together with the superalloy freeform nozzle.

The NCAME’s particular focus within this project is developing “regeneratively cooled” thrust chambers using additive manufacturing. The techniques applied should also enable light-weight and large-scale metal fabrication.

“This partnership with Auburn University and industry will help develop improvements for liquid rocket engines, as well as contribute to commercial opportunities,” comments Paul McConnaughey, deputy director of NASA’s Marshall Space Flight Center. “The technologies developed by this team will be made available widely to the private sector, offering more companies the opportunity to use these advanced manufacturing techniques.”

Vote for your Aerospace Application of the Year in the 2019 3D Printing Industry Awards. For all of the latest 3D printing aerospace news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Join 3D Printing Jobs to find your next opportunity.

Featured image shows the graphic supporting Auburn University’s $5.2 million NASA contract. Image via Auburn University