NASA has provided further updates in its mission to bring 3D printed construction to Mars with an announcement of the latest results in its 3D Printed Habitat Centennial Challenge.

The penultimate level of the challenge, Phase 3: Level 4, has been completed, which saw NASA awarding the top three teams; SEArch+/Apis Cor; Zopherus and Mars Incubator, a share of $100,000. The level centered around a Complete Virtual Construction competition, which required teams to design full-scale off-world habitats using 3D modelling software.

Launched in 2015 and managed in partnership with the Bradley University of Peroria, Illinois, the Habitat Challenge is a competition to 3D print sustainable structures for Mars using the on-site resources available on the planet. With the competition, NASA are aiming to “advance construction technology needed to create sustainable housing solutions for Earth and beyond”.

Innovative designs for sustainable 3D printing in space

NASA picked the best 3D models from three teams among a pool of eleven contestants. The entries were scored based on various categories, including architectural layout, programming, efficient use of interior space, and the 3D printing scalability and constructability of the habitat. Extra points were also given for the aesthetic representation and realism of the models. As part of the Complete Virtual Construction competition, teams prepared short videos detailing their designs alongside miniature 3D printed models that showcased the interior of their structures.

The $100,000 prize purse was distributed between the top three teams. In first place was SEArch+/Apis Cor, a team based in New York, which took away $33,954.11 for the top prize. Their design centers around the ability of continuous structural reinforcement thanks to the shape of the design. It also features trough-shaped ports on the side and top of the building to allow light to pass through.

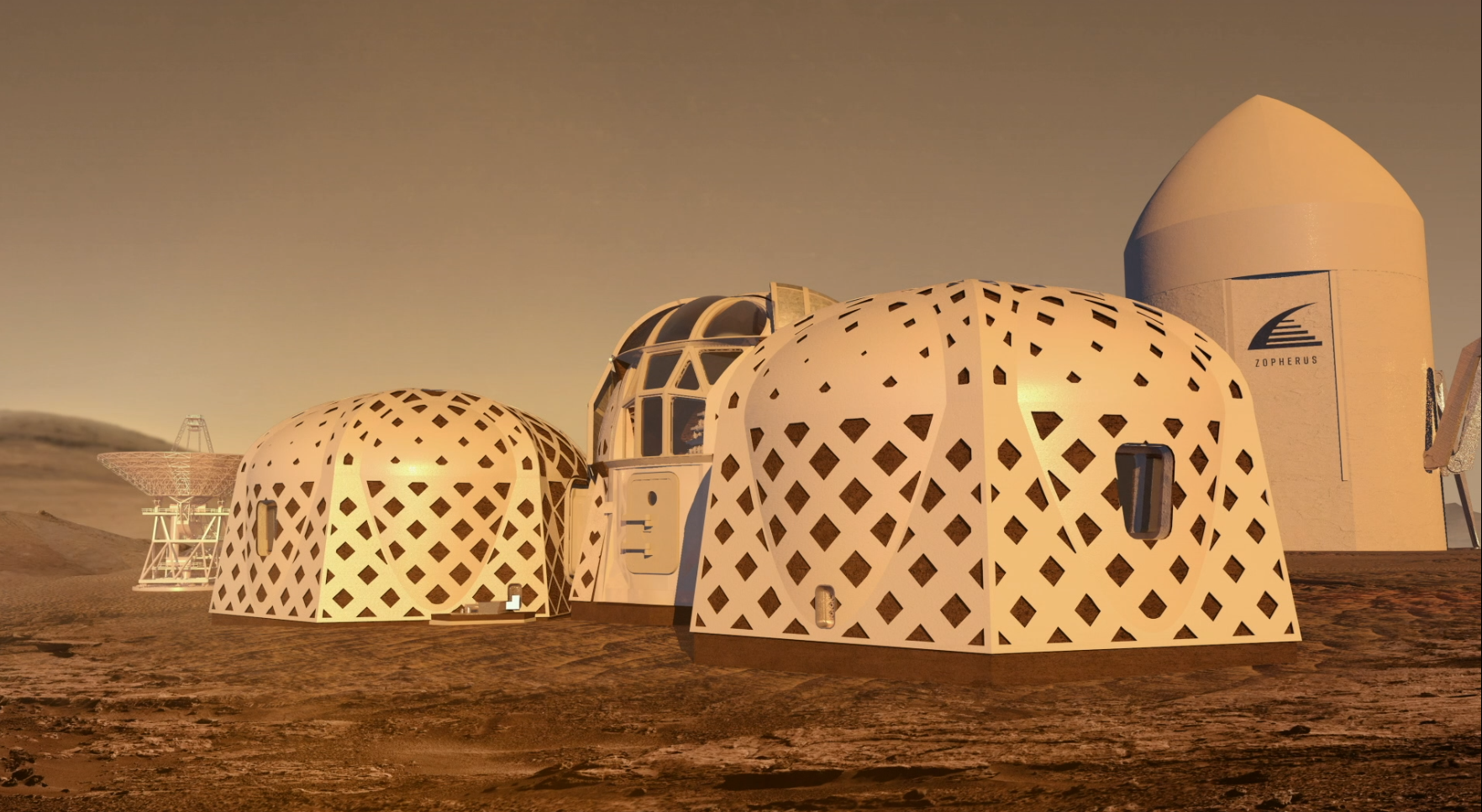

Team Zopherus from Rogers, Arkansas, won the second prize of $33,422.01. This design relies on an autonomous roving 3D printer to construct it. After 3D printing one structure, the 3D printer will then move on to another site and commence a separate construction.

Mars Incubator of New Haven, Connecticut, came third, winning a total of $32,623.88. Aimed at establishing a safe and robust environment for human life on Mars, it is divided into four volumes with different purposes, connected by bridges.

Phases of NASA’s 3D Printed Habitat Challenge

The 3D Printed Habitat Challenge is structured in phases with multiple levels, each focusing on different key areas of 3D printing to tests the teams. This includes modelling software, material development and construction. The competition began with Phase 1 in 2015, a Design Competition where teams submitted architectural details of their planned structures, with a prize purse of $50,000.

Phase 2, the ‘Structural Member Competition’ was completed in 2017, and focused on 3D printing material technology, tasking teams to create structural components for their 3D printed buildings. This Phase of the competition included a $1.1 million prize pool.

Finally, the current stage of the competition, Phase 3, is the On-Site Habitat Competition, which tests the teams on the automated construction of their 3D printed habitats. This phase comprises a total prize purse of $2 million across five different levels. With the $100,000 Level 4 stage of Phase 3 over, the entire 3D Printed Habitat Challenge will conclude in a 3D printing head-to-head of the teams structures on May 1st-4th 2019, with a prize pool of $800,000.

NASA taking off with 3D printing

The 3D Printed Habitat Centennial Challenge aims to carry out NASA’s Space Technology Mission Directorate to generate and develop ideas and practices for space and other-world exploration. Outside of the 3D Printed Habitat Centennial Challenge, NASA has made several other advancements and initiatives to incorporate 3D printing into its practices. It has explored the potential of 3D printing in space in order to minimize the cost of spare parts and enable in-situ resource production in the future, as part of its in-space manufacturing (ISM) roadmap. NASA has also installed the Refabricator system by the US-based aerospace company Tethers Unlimited Inc. on the International Space Station (ISS) to further carry out this goal.

Furthermore, NASA has also allotted $2 million to its scientist Mahmooda Sultana to develop 3D printed multisensor devices for space exploration, as well as recently developing and 3D printing a new copper-based alloy for use in its rocket propulsion components.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows team SEArch+/Apis Cor’s 3D modeled design. Image via Team SEArch+/Apis Cor.