Award-winning OEM GE Additive is to provide consultation to General Atomics Aeronautical Systems Inc (GA-ASI), a U.S. aeronautics company. Fulfilled by the company’s AddWorks service, the aim of this collaboration is to accelerate GA-ASI’s integration of metal additive manufacturing.

“Some of our AddWorks consultants are responsible for designing and then industrializing many of the additively manufactured aerospace parts that are in service today,” said Jason Oliver, President & CEO, GE Additive.

“By offering our learnings and in-depth knowledge of the aerospace and defense industry, we will be able to assist them in leveraging metal additive with our methodical, systematic approach, that meets the exacting requirements of the sector and their aggressive goal to grow the impact of additive within their application space.”

GE Additive AddWorks

Founded in 1993, GA-ASI is a leading manufacturer of Remotely Piloted Aircraft (RPA) systems, radars, electro-optic and related mission systems. With GE Additive’s AddWorks team, GA-ASI is looking to strengthen the qualification and implementation of metal additive manufacturing in both its products and processes.

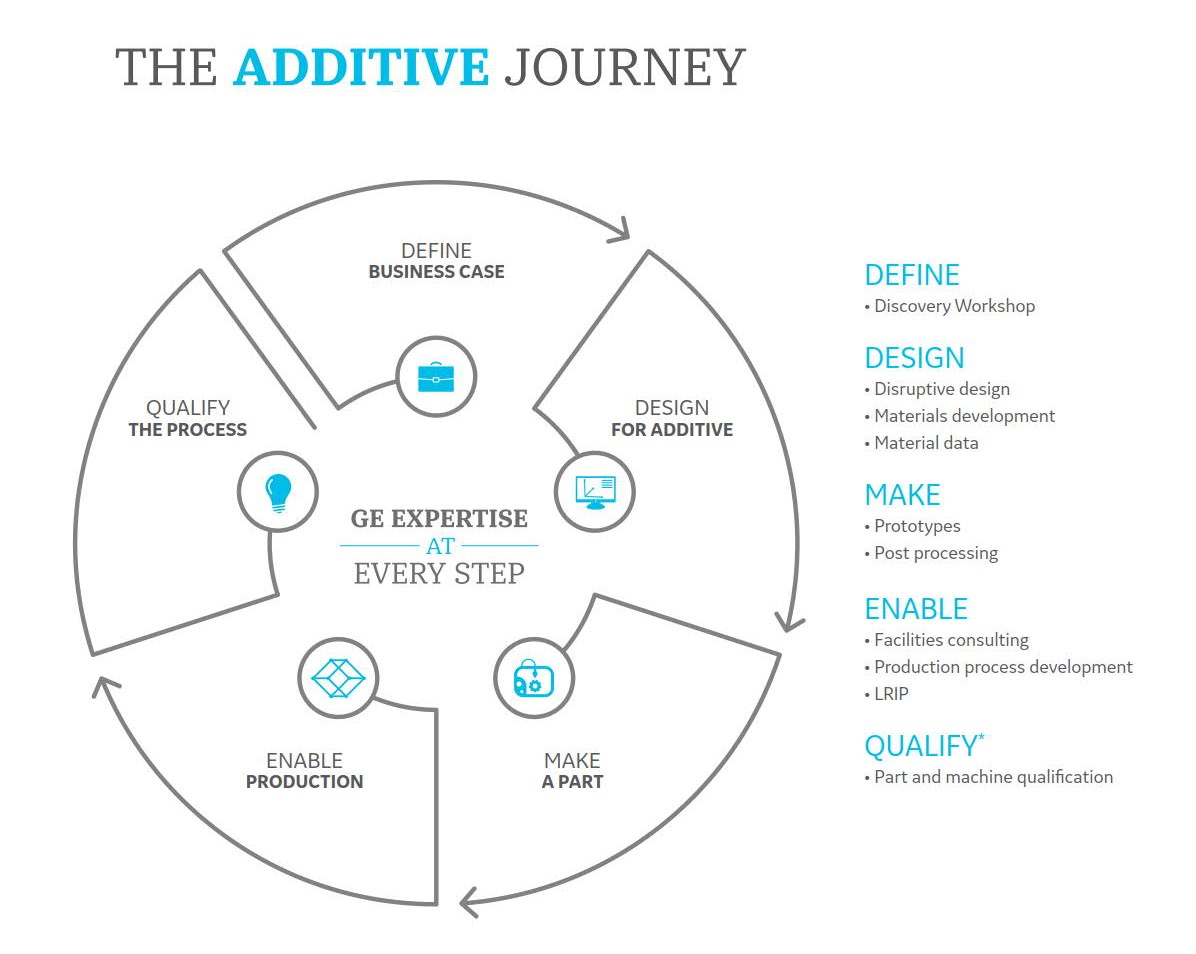

AddWorks provides a step by step guide for industrial 3D printing. As with previous partners, Honda R&D Co. Ltd., in Japan, and America’s Triumph Group, the consultation begins by defining the business case, building a team, and identifying funding opportunities.

Following this, training in Design For Additive Manufacturing design (DfAM) is given to engineers in the company. As part of this, trainers describe various aspects for the production of 3D printed parts, such as: printing location, support structure recommendation, infrastructure, and certification.

Consultation is then given on establishing a facility, scaling production, environmental, health, and safety (EHS) issues, and material handling requirements. Once these steps are completed the qualification process commences for certifying the 3D printed parts with a company’s target industry in mind.

Accelerating additive manufacturing adoption

With a substantial investment in metal additive manufacturing, GE Additive is committed to increasing the technology’s adoption in a number of different ways. In education, the company launched the Additive Education Program to grow the number of skilled 3D printing individuals. As part of an industry-wide industrialization plan, the company has also launched its Manufacturing Partner Network (MPN), comprising a leading list of industry stakeholders such as Burloak Technologies, Carpenter Co and Protolabs.

Concluding the announcement of GA-ASI’s collaboration with AddWorks, Oliver adds, “We’re] very well-placed to accompany GA-ASI in accelerating their additive journey. We’re honored to secure this engagement and look forward to helping them drive successful outcomes and their competitive advantage.”

Voting for the 2019 3D Printing Industry Awards is now open. To see if your nominations made the shortlist, and to help decide this year’s winners, cast your votes now.

For the latest academic additive manufacturing research, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the General Atomics MQ-9 Reaper. Photo via GA-ASI.