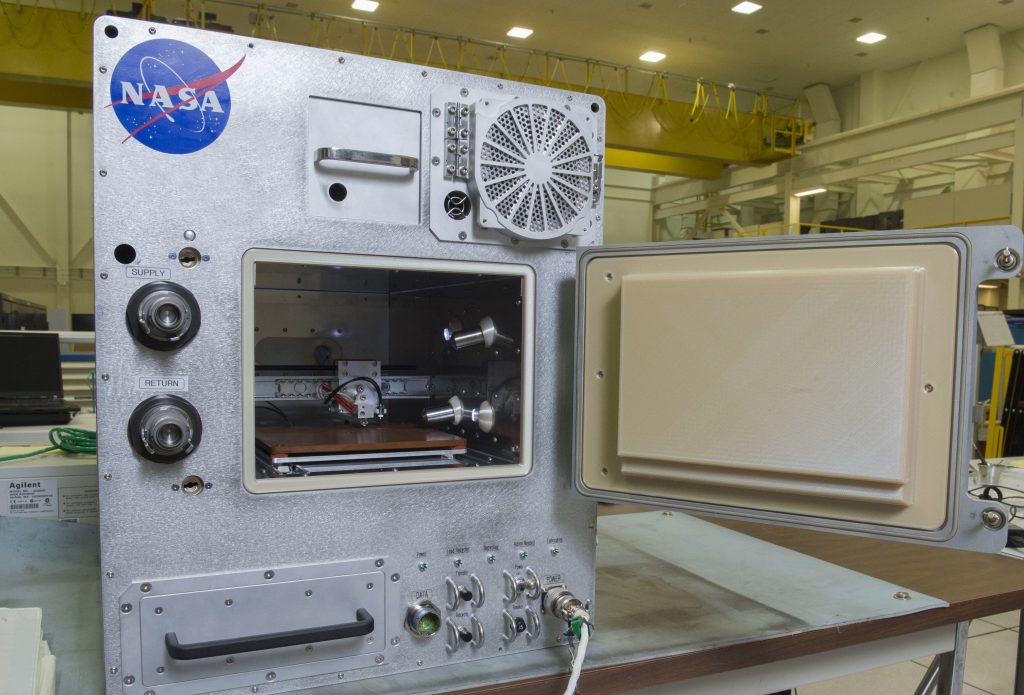

Robust and refrigerator-like, the ‘Refabricator’ is poised to lead NASA’s recycling initiative for astronauts aboard the International Space Station (ISS). Set to launch 2018, the machine is capable of crunching plastic parts back into raw materials, and 3D printing them anew as tools and spare parts.

Preparing for “space at a premium”

NASA has awarded approximately $750,000 to the Refabricator project, taken on by Seattle-based space technology company, Tethers Unlimited Inc.

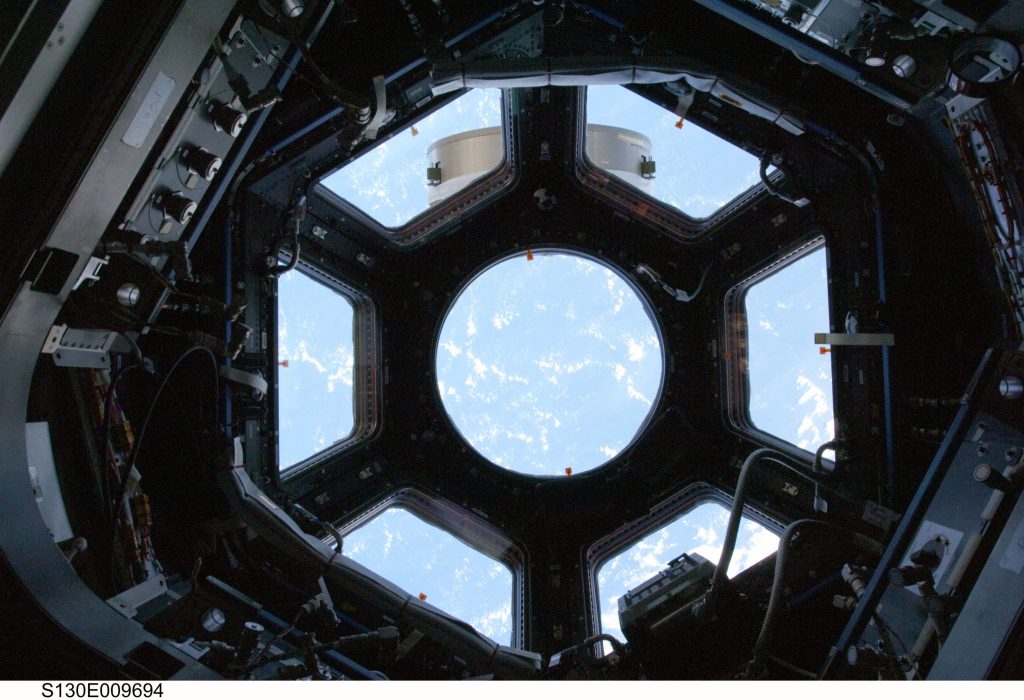

Niki Werkheiser, manager of In-Space Manufacturing at NASA’s Marshall Space Flight Center who will test the machine, comments “When we begin launching humans to destinations beyond low-Earth orbit, space will be at a premium.”

“It simply won’t be feasible to send along replacement parts or tools for everything on the spacecraft, and resupplying from Earth is cost and time prohibitive. The Refabricator will be key in demonstrating a sustainable logistics model to fabricate, recycle, and reuse parts and waste materials.”

“The next generation of space systems”

While there is no mention yet of the Refabricator re-purposing biological materials, like yeast, into 3D printer filament, the machine will also be capable of reusing and 3D printing metal – a technology that is yet to take off in space.

Rob Hoyt, CEO of Tethers, comments, “The Refabricator demonstration is a key advance toward our vision of implementing a truly sustainable, in-space manufacturing ecosystem,”

“Astronauts could use this technology to manufacture and recycle food-safe utensils, and turn what is now inconvenient waste into feedstock to help build the next generation of space systems.”

“We believe re-using the waste could reduce the cost and risks for NASA and private space exploration missions.”

Limitless possibilities on the final frontier

Aboard the ISS, the Refabricator will work alongside Made In Space’s Additive Manufacturing Facility (AMF), contributing to the development of an off-world FabLab. Werkheiser explains, “The FabLab would allow astronauts to select what they want or need from a catalogue of parts and then simply push a button to have it made.”

Eventually, the lab will be able to 3D print complex and multi-material parts on demand, a key development for applications both on Earth and in space.

A similar reduce, reuse, recycle project using plastic on Earth is 3DEVO’s SHR3D IT hardware, previewed by 3D Printing Industry at Formnext 2016.

Read more about the latest additive manufacturing on Earth and beyond with the free 3D Printing Industry newsletter, on Facebook and on Twitter.

Check out the latest 3D printing events here.

Featured image: NASA and Tethers Unlimited Inc. Refabricator recycler and 3D printer, due for launch on the ISS 2018. Photo via: NASA/MSFC/Emmett Given