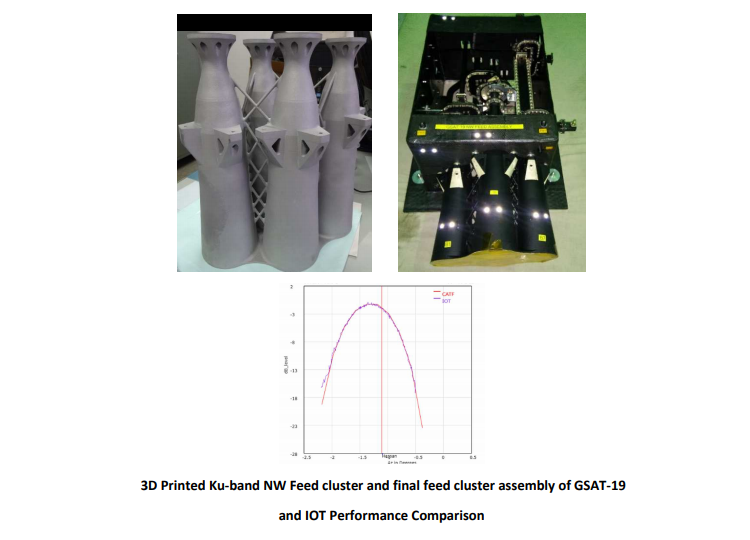

Wipro, an Indian IT services corporation has successfully collaborated with German additive manufacturing giant EOS to produce a 3D printed functional metal satellite component. The “North West Feed Cluster”, was printed in aluminium for the Indian Space Research Organisation’s GSAT-19 communications and research satellite launched on 5th June 2017.

According to EOS, this marks “the first 3D functional component for India”, an emerging hub for 3D printing.

Cost-effective satellite components

As with all 3D printed components, reducing a complex component from multiple parts to a single body results in lower costs and faster production. It also cuts down the post-processing time required for the component after production, allowing more prototypes per week to be completed for testing.

More importantly for space satellites, 3D printing a part enables the design to be adjusted so as to make it lighter. Since companies are charged for satellite launches are charged according to the payload (mass), more fuel can be placed on the satellite’s bus for the same cost. In the case of GSAT-19, which weighs over 3 tonnes, every effort must be made to make the payload as efficient as possible. Finally, when dealing with telecommunications, having a more specialised design and minimising the number of components makes the satellite more effective by reducing the leakage of radio frequencies.

All of these adjustments made to the satellite component would be very difficult to accomplish without first generating a model and 3D printing the result.

The significance

3D printing technology has been successfully used in space satellite components for over 2 years, with some satellites now entirely 3D printed. As the number of satellite launches increases and more companies look to make them as cost effective as possible, 3D printing looks likely to play an even greater role in telecommunications both in the air and on the ground.

For more on aerospace applications to 3D printing, sign up for our newsletter. Like us on Facebook too.

Featured image: simulation of the GSAT-19 in space. Photo via DNA India.