“If astronauts are going to make journeys that span several years, we’ll need to find a way to reuse and recycle everything they bring with them,” says Mark A. Blenner, assistant professor of chemical and biomolecular engineering at Clemson University, South Carolina.

To this end, the Blenner Research Group is looking into the potential uses of a type of yeast called Yarrowia lipolytica, that feeds on the urea content of urine.

With a little genetic engineering the group has proven that the yeast can be used to produce hydrogen and carbon – the atomic ingredients of nutrients like Omega 3, and polyester-based 3D printer filament.

The ultimate survival environment

Space pushes astronauts to the ultimate limits of survival. All sustenance, oxygen and resources needed for a particular expedition must be carried by flight crew and carefully maintained in order to thrive.

Since 2009, the International Space Station (ISS) has alleviated some of the challenges in a system that can convert astronaut’s urine into water using iodine.

From 2015, the ISS has also been researching ways to cut-down on the resource-heavy cargo with an on-board Additive Manufacturing Facility (AMF).

3D printing in space

The AMF, provided by California’s Made in Space, is capable of 3D printing tools and spare parts from high-grade PEEK plastic. Eventually, astronautical engineers will be able to scale-up the productivity on systems like the AMF and produce larger parts, for structural purposes and even colonizing Mars.

These 3D printers however need materials, and the use of Y. lipolytica is a new, intriguing route of investigation.

Reduce, reuse, recycle

One popular method of sustaining 3D printers in space looks at the use of a powdered rock, like that on surface of the Moon and Mars, to make materials.

This method may still need the use of mining equipment however, and it is much more efficient to be able to recycle products already at an astronaut’s disposal.

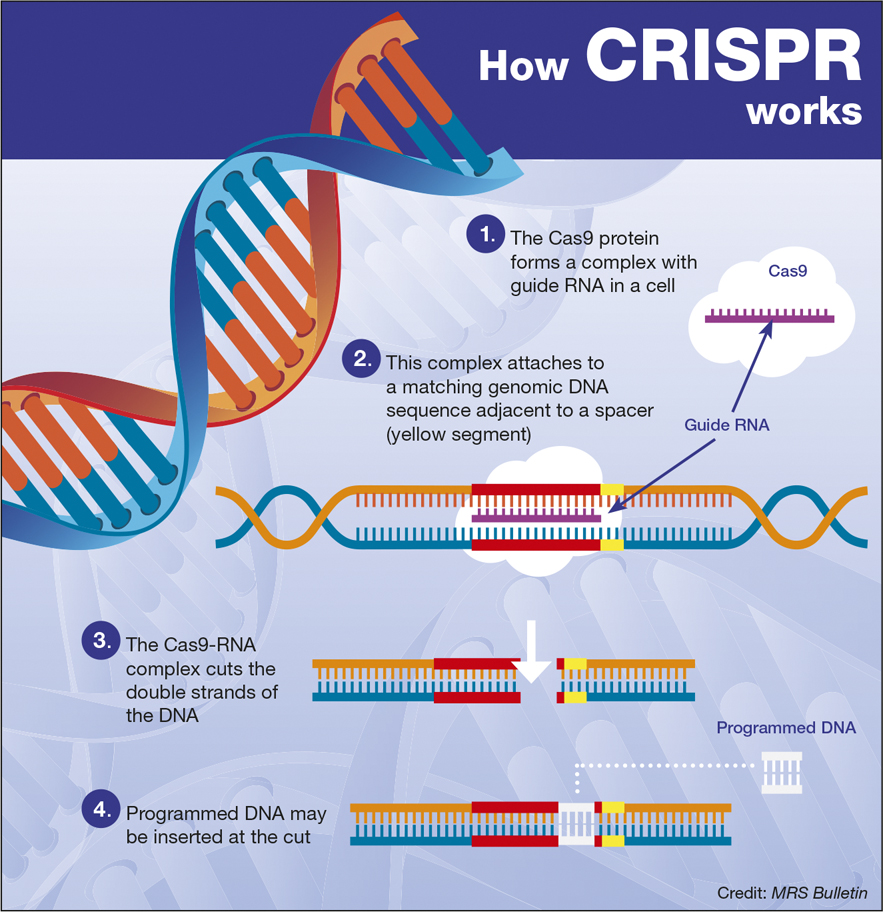

Y. lipolytica yeast could be cultured on urea extracted in the urine purification process aboard the ISS. To make plastic, the genome of the microbe would then need to be edited using a process similar to CRISPR/Cas9 technology.

Gene splicing

Genome editing processes are based on CRISPR DNA sequences that are the backbone of the body’s immune system. When attacked by viruses, CRISPR bacteria proteins keep a record of the infection to effectively prepare for other outbreaks.

By introducing other combinations to the CRISPR matrix, scientists are capable of instilling new properties into bacteria, and even storing data on the strands.

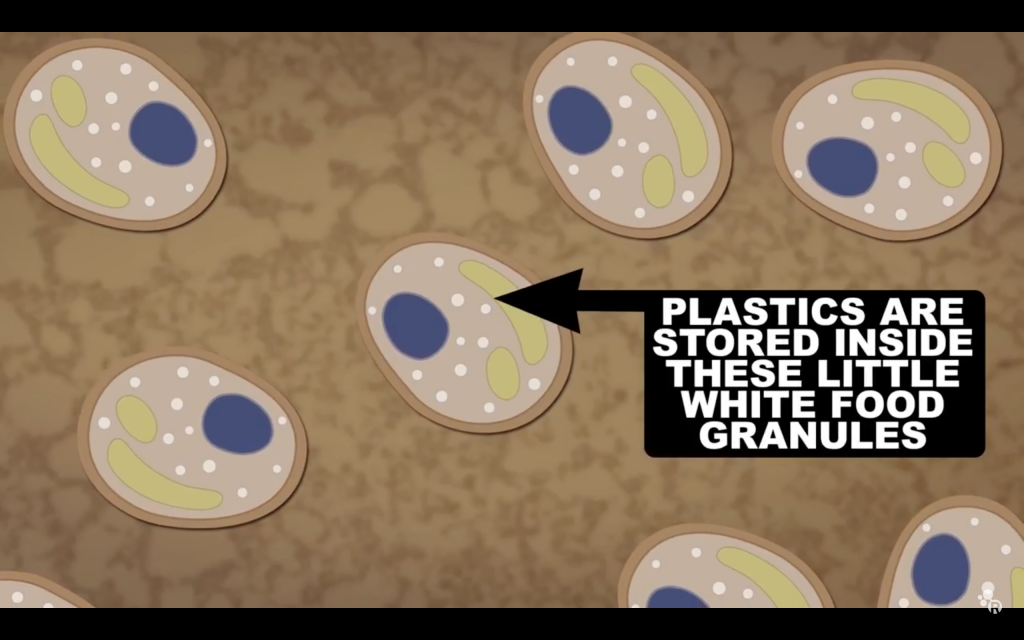

In Blenner’s project, which is funded by NASA’s Space Technology Research Grants Program, Y. lipolytica can be tuned this way so that it produces a polyester granule instead of its typical carbon molecules that it uses as nutrients.

A quirky yeast

The challenge now is to extract the molecules from the nutritional storage of Y. lipolytica bacteria at volume, so it can be mixed into an ink, or a filament.

There may even be a way to directly use the genetically tuned yeast as 3D printer feedstock.

Blenner comments, “We’re learning that Y. lipolytica is quite a bit different than other yeast in their genetics and biochemical nature. Every new organism has some amount of quirkiness that you have to focus on and understand better.”

A study of Y. lipolytica by the Blenner Research Group was presented at a meeting of the American Chemical Society under the forthcoming paper title “Biosynthesis of materials and nutraceuticals from astronaut waste: Towards closing the loop.”

Read all about the latest 3D printing research in our free newsletter, on Facebook and on Twitter.

Register for your next career move now on our dedicated 3D printing jobs site.

Featured image: Yarrowia lipolytica yeast under the microscope. Image by Wikimedia Commons contributor A doubt