Researchers from NASA have developed and 3D printed a new copper-based alloy for use in rocket propulsion components.

GRCop-42, a high strength, high conductivity copper-based alloy, was created by a team from the NASA Marshall Space Flight Center (MSFC) in Alabama and the NASA Glenn Research Center (GRC) in Ohio.

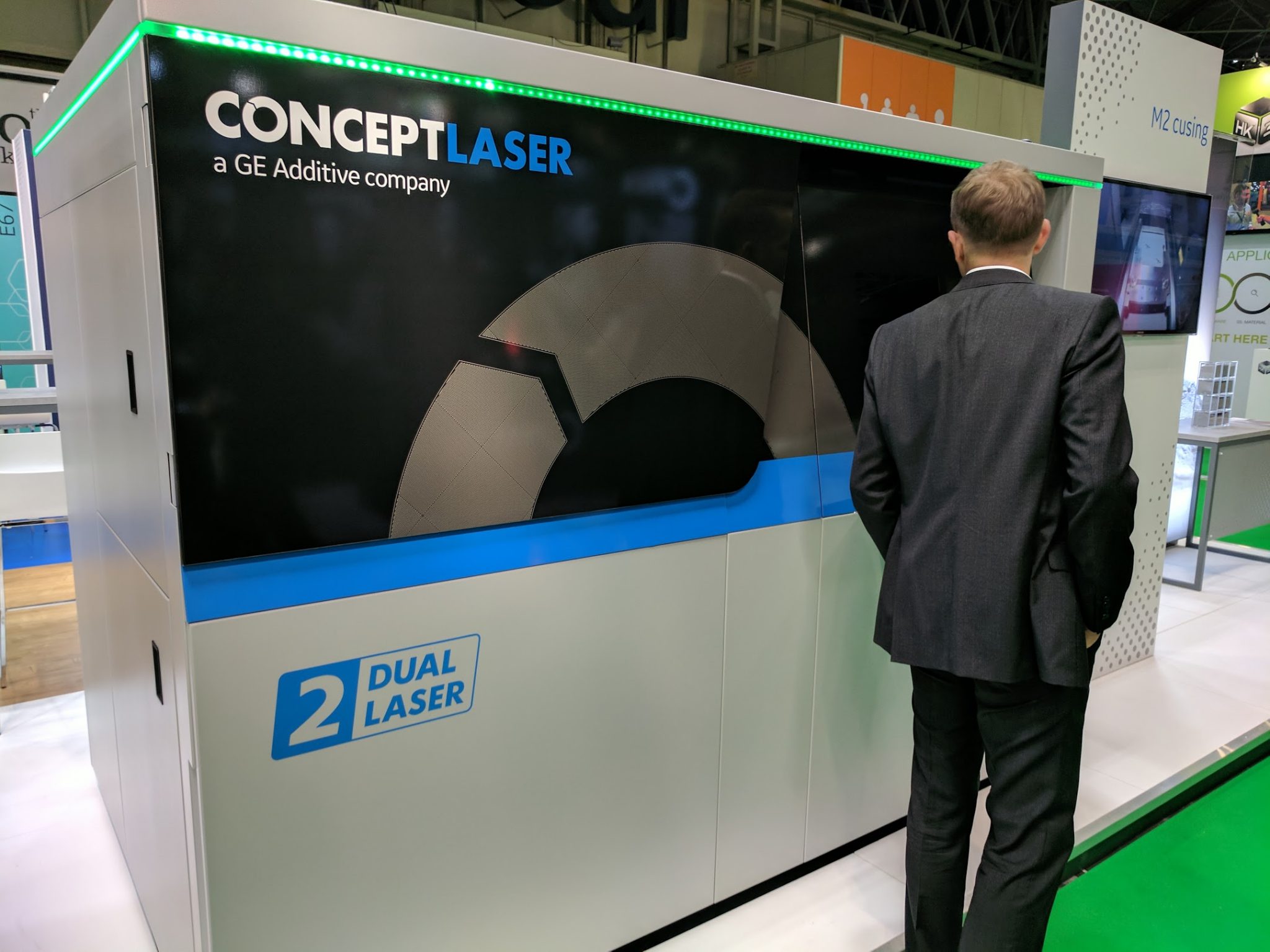

The result metal powder used to produce near-fully-dense 3D printed parts such as combustion chamber liners and fuel injector faceplates with a Concept Laser M2 3D printer, a Powder Bed Fusion (PBF) AM system.

Developing aerospace-grade alloys

As detailed in the review published in the NASA Technical Reports Server (NTRS), in 2014, NASA engineers commenced the development of GRCop-84, the predecessor of GRCop-42, to establish more readily available powder suppliers for combustion chamber based hardware.

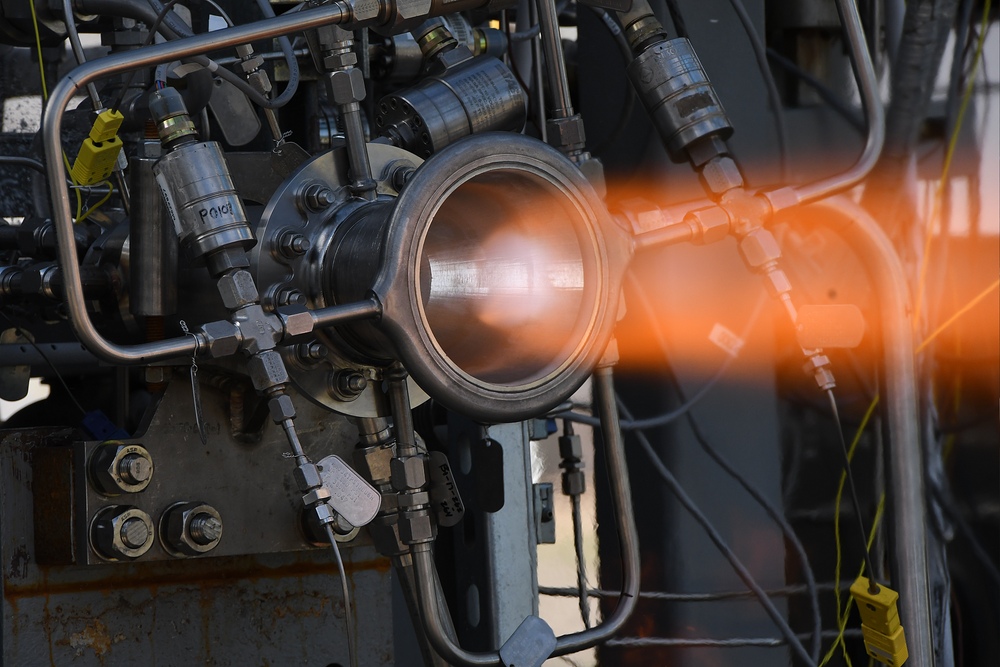

Following hot-fire tests of 3D printed GRCop-84 components at MSFC in 2016 and 2017, the team began developing GRCop-42 for higher thermal conductivity at similar strength; this would also allow for components within propulsion engines that “exceed their traditionally manufactured predecessors”, stated the researchers.

Throughout 2018, the NASA team conducted tests of the metal power, proving its processability through metal additive manufacturing. The researchers explain, “The rationale for choosing this machine is primarily that it was used in the GRCop-84 development and had proven itself ‘copper friendly’. With its inert glovebox and build chamber, and the 400 W laser [it] could readily achieve the high-energy density needed to fully melt the 42.”

3D printed rocket components

25 small blocks were 3D printed using GRCop-42 with 50% thicker layers (0.045mm) from the GRCop-84. The researchers observed that this allowed the components to cool faster. These parts were then put through MSFC’s hot isostatic press (HIP), a manufacturing process used to reduce the porosity of metals, and then shipped to GRC for additional post-processing and room temperature tensile testing.

It was found that the 3D printed metal components made from GRCop-42 demonstrated high thermal conductivity, excellent creep (deformation) resistance, and strength at elevated temperatures.

The NASA team now intends to validate its parameter set of GRCop-42 by running several extensive tests with larger builds.

“Three-Dimensional Printing GRCop-42” is co-authored by K.G. Cooper, J.L. Lydon, M.D. LeCorre, Z.C. Jones, D.S. Scannapieco, D.L. Ellis, and B.A. Lerch.

Voting for the 2019 3D Printing Industry Awards is now open. To see if your nominations made the shortlist, and to help decide this year’s winners, cast your votes now.

For the latest aerospace additive manufacturing, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows hot test firing of an Aerojet Rocketdyne Space Shuttle Main Engine (SSME). Photo by Aaron Cunningham/NASA