NASA scientist Mahmooda Sultana and her team have received $2 million to develop 3D printed multisensor devices for space exploration.

Sultana is Associate Branch Head of the Systems Engineering Branch at NASA’s Maryland-based Goddard Space Flight Center. On receiving the grant Sultana said, “We’re really excited about the possibilities of this technology.”

“With our funding, we can take this technology to the next level and potentially offer NASA a new way to create customized, multifunctional sensor platforms, which I believe could open the door to all types of mission concepts and uses.”

NASA nanotechnology expert

Last year, Sultana and her team developed multifunctional sensors using the Nanoscale Offset Printing System (NanoOPS) developed at Northeastern University by Professor Ahmed Busnaina and his team. These sensors were made of various nanomaterials including graphene and carbon nanotubes.

Sultana explained, “The sensors were found to be quite sensitive, down to low parts per million. With ECI we are targeting parts-per-billion sensitivity by improving sensor design and structure.”

Preceding this development, in 2017, Sultana also won the IRAD Innovator of the Year. At the award ceremony, Peter Hughes, Goddard Chief Technologist, said, “[Sultana] has successfully competed for 10 awards under our IRAD programme […] including the creation of advanced sensors for which a patent is pending […] Perhaps most notable is her emergence as one of NASA’s experts in nanotechnology.”

Nanoscale Offset Printing System

With the $2 million grant Sultana’s team will be specifically looking to develop smaller spectrometers. Used to measure properties of light over the electromagnetic spectrum, spectrometers are a useful tool for identifying materials. Such devices are used in astronomy to understand the composition of stars and planets. Currently, spectroscopy devices are generally too large to be easily transported to space.

Continuing the partnership with Northeastern University, Sultana and her team are attempting to fabricated spectrometers and other multisensory devices on a single platform using NanoOPS.

The NanoOPS technology works differently from other nano 3D printing technologies, e.g. two photon polymerization, which is a photo-curing process. In contrast, NanoOPS dips a substrate wafer with a template into a well of nanomaterial. The nanoparticles stick to the template when an electrical charge is applied, and the material is built up layer by layer this way. The process is known as electrophoresis.

Multilayer sensors

NanoOPS is capable of building macro to nano multilayer sensors. Using the NanoOPS technology, Sultana and her teams’ job is to make multilayer sensors which can measure parts-per-billion concentrations of chemicals, such as ammonia and methane, in the atmosphere.

Sultana said, “The beauty of our concept is that we’re able to print all sensors and partial circuity on the same substrate, which could be rigid or flexible. We eliminate a lot of the packaging and integration challenges […] This is truly a multifunctional sensor platform. All my sensors are on the same chip, printed one after another in layers.”

“The same approach we use to identify gases on a planetary body also could be used to create biological sensors that monitor astronaut health and the levels of contaminants inside spacecraft and living quarters.”

NASA and other space agencies are making extensive use of 3D printing to accelerate the flight to Mars and Moon. Multisensor devices, the kind developed by Mahmooda Sultana can be affixed to rovers and satellites, and take mankind a step closer to the extraterrestrial planets.

Nominations for 3D Printing Awards 2019 are open. Nominate the best research team now.

For more 3D printing news subscribe to our 3D printing newsletter or join us on Facebook and Twitter.

We also have a lot of jobs for you in the industry, visit our 3D Printing Jobs to learn more.

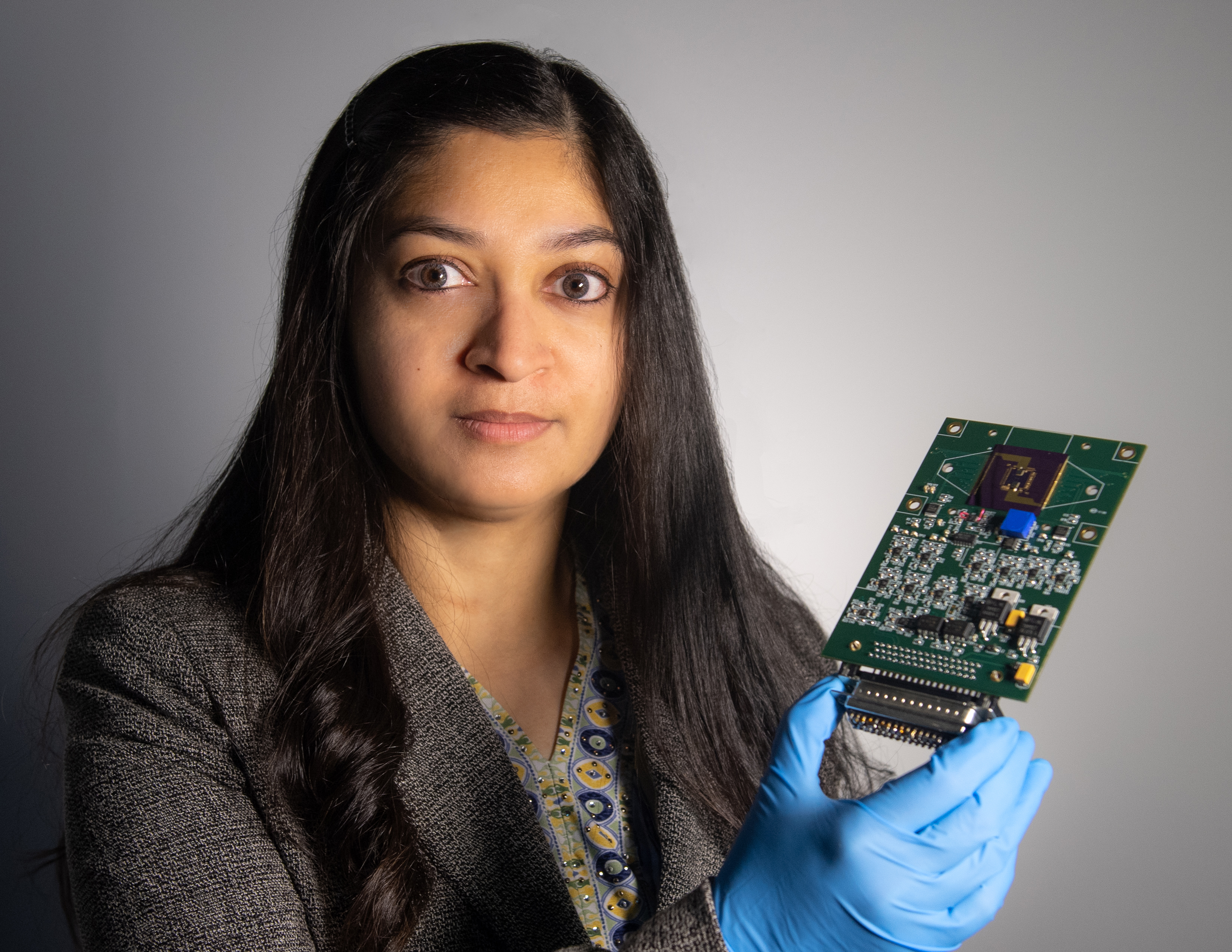

Featured image shows Mahmooda Sultana holding a multifunctional sensor platform. Image via NASA.