After seeing the smart wood at CES 2019 we knew it would only be a matter of time before a 3D printed smart wood came along.

For some time it seems, teams at Simon Fraser University (SFU), British Columbia, and the Applied Wood Materials Laboratory at the Swiss Federal Laboratories for Materials Science and Technology (EMPA) have been working on their own wood-derived electronics.

Using 3D printing, the collaborative has now proved the ability to create wireless, eco-friendly and disposable chemical sensors in an effort to replaced the plastic of common PCBs.

Electric wood

SFU and EMPA’s work on 3D printed bio-electronics uses nanocellulose. Typically extracted from woodpulp, this pseudo-plastic structural material is finding various applications in the medtech field, and even food technology. In this project however, the teams look broadly at the material’s potential to create electronics, testing the conductive potential of cellulose nanofibers (CNFs) and cellulose nanocrystal (CNCs) when combined with a silver nanowire (AgNWs).

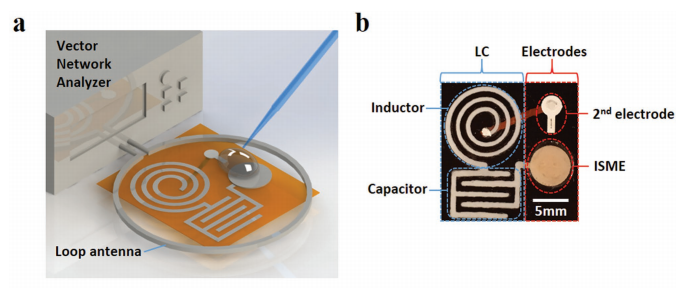

In the experimentation, inks made using these base ingredients are tested to find the optimal solution. The best one (a CNF mixture) is chosen for 3D printing as an inductor-capacitor (LC) circuit onto a polyamide film. Then, when an electric charge is applied to the circuit (via an attached box), data can be gathered wirelessly from the 3D printed sensor by measuring radio frequency.

3D printing green electronics

According to Woo Soo Kim, SFU professor at the School of Mechatronic Systems Engineering, the findings of this latest research will help advance the field of “green electronics,” i.e. devices made from recycle components, like Dell’s motherboard jewelry, or those using biodegradable materials. “If we are able to change the plastics in PCB to cellulose composite materials,” adds Professor Kim, “recycling of metal components on the board could be collected in a much easier way.”

Suggested areas of application for the sensors include biomedicine, and environmental detection – a field which is becoming increasingly important as the planet seeks to manage the Earth’s pollution.

“Electrochemical Sensors: 3D Printed Disposable Wireless Ion Sensors with Biocompatible Cellulose Composites” is published online in Advanced Electronic Materials. It is co-authored by Taeil Kim Chao Bao, Michael Hausmann, Gilberto Siqueira, Tanja Zimmermann and Woo Soo Kim.

Does this research get your nomination for this year’s 3D Printing for a Better World award? Select SFU, EMPA and more as your nominees of the 2019 3D Printing Industry Awards now.

For more news on the latest research in additive manufacturing, subscribe to our 3D printing newsletter. You can also join us on Facebook and Twitter.

Looking for a job in the industry? Then visit our 3D Printing Jobs board.

Featured image shows Professor Woo Soo Kim holding a 3D printed cellulose-based sensor. Photo via SFU