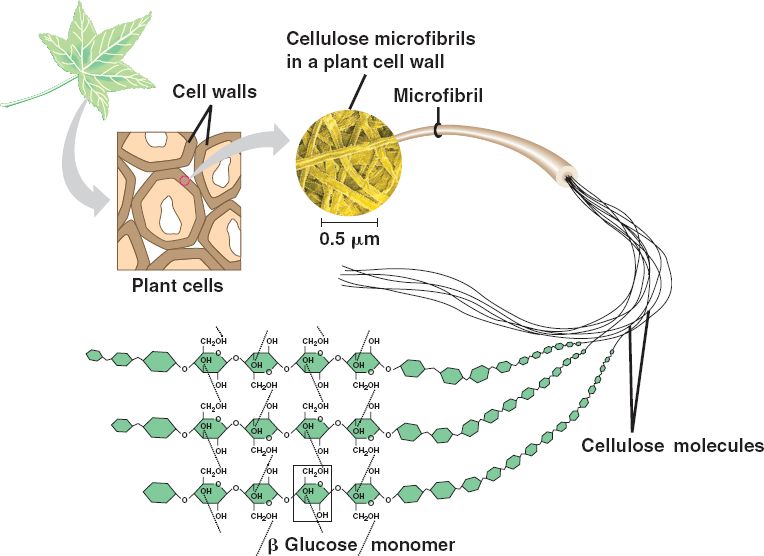

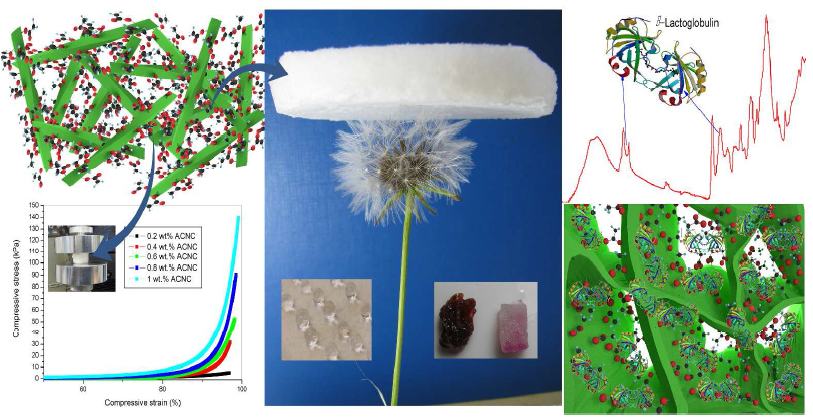

Developed in the late 1970s at the ITT Rayonier labs in Whippany, New Jersey, nanocellulose, is a fibrous, fibrillated or crystalline form of cellulose – the primary building block in the cell walls of green plants. As a material, nanocellulose is heralded as a natural reinforcement in material fabrication, and is commercially used as a low-calorie thickener, flavour carrier and stabilizers for some foods.

One of the most appealing properties of cellulose in food is that, if applied correctly, it can leave people feeling fuller for longer, so high fat sugary snacks and cakes could become all the more guilt free in the future. The challenge however is adding cellulose to foods in a way that makes it palatable.

3D print, cook, bake, fry and grill

The Yissum Research Development Company of the Hebrew University of Jerusalem is the latest institution to introduce a nanocellulose-based platform that promises “the 3D printing of personalized food” with the added ability “to cook, bake, fry and grill while printing at the three dimensional space.”

The technology has been presented by Professor Ido Braslavsky, Head of university’s B.Sc. Program at the Institute of Biochemistry, Food Science, and Nutrition, and Professor Oded Shoseyov, fellow faculty member and founder of biotechnology materials company CollPlant.

The multidisciplinary approach

Professor Braslavsky’s expertise is in the study of food biophysics and antifreeze proteins, that naturally prevent living organisms like fish, plants and insects from dying in sub-zero conditions. Both areas will be instrumental in micromanaging the molecular content of foods.

Complementing Professor Braslavsky’s area of interest, Professor Shoseyov specializes in the molecular biology of plants. He is credited on a number of research papers and patents for the production and construction of nanocellulose.

The purpose of their team’s combined effort at Yissum is, “to better control composition of foods and restrict caloric content on a much wider scale to minimize the obesity epidemic and the harmful diseases associated with it (diabetes, heart disease, etc.)”

The concepts developed by the team, in theory, can be tailor-made with respect to dietary requirements, i.e. gluten-free, vegan, and vegetarian options.

A “truly revolutionary concept”

According to Yaron Daniely, President and CEO of Yissum, “This promising technology is an excellent example of the kind of multidisciplinary, transformational inventions that originate from our Faculty of Agriculture, Food and Environment and from the Hebrew University in general.”

“The ability to automatically prepare, mix, form and cook personalized food in one device, is a truly revolutionary concept.”

The Hebrew University of Jerusalem however is not the only institute to be looking into the nutritous potential and 3D printability of nanocellulose.

Binder jetted cellulose

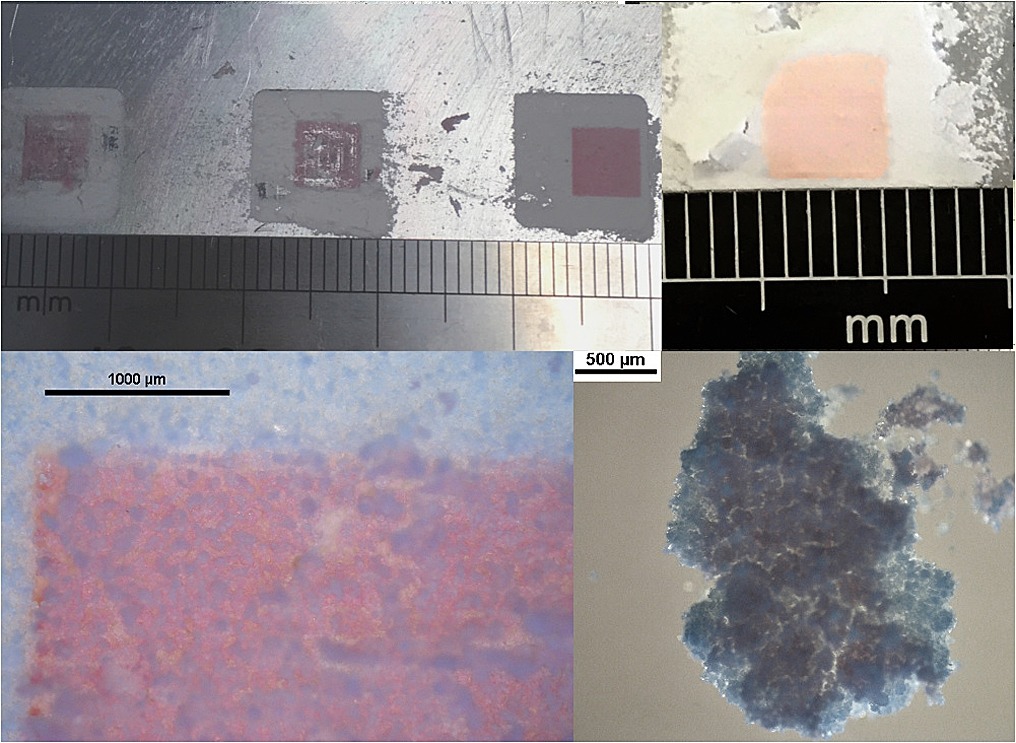

In the most recent study from the 3D Printing and Additive Manufacturing Research Group and Division of Food Science at the University of Nottingham in the UK, researchers present the Design and characterisation of food grade powders and inks for microstructure control using 3D printing.

In the experiment, cellulose is combined with Xantham gum, another common food additive, to create food grade inks that could be successfully 3D printed using binder jetting technology.

A multimillion pound opportunity

Working with Nottingham and two other universities in the UK, the Engineering and Physical Sciences Research Council (EPSRC) and the UK Knowledge Transfer Network (KTN) has also launched a £5.6 million project to promote additive manufacturing in the food industry.

Speaking at the time of the announcement in 2016 Dr. Jennie Lord, the EPSRC’s National Center Manager and Technology Translator, commented “To bring around complex formulations that can be applied to 3D printing, we need a liquid that can solidify […] We are looking at bypassing water inefficiency and moving to dry powder that can be reconstituted. We believe with AM, we address real industrial needs.”

Is nanocellulose the answer?

This year, through a high-profile partnership with CSM Bakery Solutions a global leader in culinary ingredients, products and services, 3D Systems made its entry into the UK food market. At present, the 3D Systems ChefJet Pro 3D printer can be used to make bespoke, sugar-work cake decorations.

Though there’s no denying the additive technology could benefit the way food is made, the technology has yet mature into a non-tentative approach for such a highly automated, and health regulated industry. Nanocellulose, on this account, may be just the ingredient that gives researchers a slice of the cake.

Never miss a story again – subscribe to the 3D Printing Industry newsletter, like and follow. Register for 3D printing job updates here.

Featured image shows green romanesco broccoli, an example of cellulose containing vegetation. Photo by Mr. Theklan on Flickr