Whether you’re a fan of folding paper or life-saving medical procedures, you’re going to love the work that Brigham Young University is doing with small-scale surgical devices. BYU mechanical engineering professors Larry Howell and Spencer Magleby have pioneered a new generation of tools that will make surgery less invasive and they’ve relied on 3D printing and origami to do it.

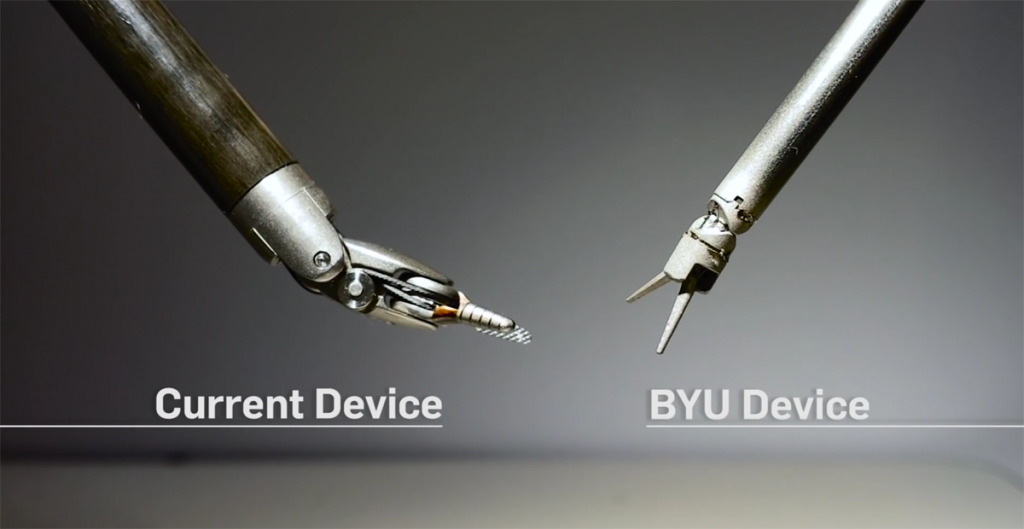

Tools like the da Vinci robot from Intuitive Surgical are designed to reduce the size of an incision necessary to perform a medical procedure. And who wants a big clunky machine tinkering inside of your body? But the BYU engineers aren’t satisfied with even the size of those tools, leading them to create devices so small that the incisions they cause can heal by themselves, without stitches. Prof. Howell tells BYU news, “The whole concept is to make smaller and smaller incisions. To that end, we’re creating devices that can be inserted into a tiny incision and then deployed inside the body to carry out a specific surgical function.”

In order to create such tiny tools, the BYU team had to get rid of the clunky pin joints and other parts that allow surgical devices to move. Instead, they’re using the deflection seen in origami to cause the instruments to move. Like an origami swan, as one side of the object is tugged, the other side contracts, particularly useful for small clamps and claws. For instance, with this technique, the team was able to fabricate a set of robotically-controlled forceps that can be inserted into an incision just 3 mm in size, about the thickness of two pennies stacked on top of each other.

Magelby says that this technique will inspire a whole new series of medical tools, “These small instruments will allow for a whole new range of surgeries to be performed—hopefully one day manipulating things as small as nerves. The origami-inspired ideas really help us to see how to make things smaller and smaller and to make them simpler and simpler.” For that reason, Intuitive Surgical has begun licensing the BYU technology themselves.

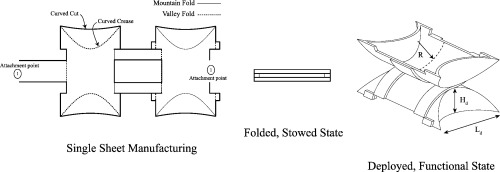

In addition to the work being licensed to Intuitive Surgical, the BYU researchers have developed an even more exciting device that actually starts as a flat piece of material before expanding to become two rounded surfaces that roll on each other. This item, dubbed the “D-Core”, is actually mean to resemble the movement made by discs in the spine.

The BYU team, which uses 3D printing both to prototype scale models of their tools and to produce the end result, has not only applied their engineering wits to the medical field. NASA, too, has turned the BYU crew and the principals of origami to create equipment launched into space. Just as medical devices need to be small to reduce recovery times, satellites need to take up as little cargo space as possible, Magleby says. “Those who design spacecraft want their products to be small and compact because space is at a premium on a spacecraft, but once you get in space, they want those same products to be large, such as solar arrays or antennas,” Magleby said. “There’s a similar idea here: We’d like something to get quite small to go through the incision, but once it’s inside, we’d like it to get much larger.”

This space work will likely change as an increasing number of organizations, like Made In Space, explore 3D printing within the vacuum of space itself, but anyone who’s gone under the knife will agree that they’d like those incisions to be as tiny as possible.