REAL 2016 has officially begun, and though the conference is sponsored by the 3D tech pioneers at Autodesk, much of the excitement here is revolving around startup companies who are vying for more solid footing in the realm of 3D technology. For the first time at the REAL event, this year will feature “The REAL Deal Startup Competition”, which will allow four startup companies to present their business model to both the audience and an experienced panel of VC judges, featuring Zack Schildhorn (Lux Capital), Sven Strohband (Khosla Ventures), and Trae Vassallo (Independent Investor/Consultant). There are a number of other startup companies presenting throughout REAL, many of whom we will cover throughout the week, but once the REAL 2016 curtain officially arose, all of the attention was directed onto these four competing startups in particular.

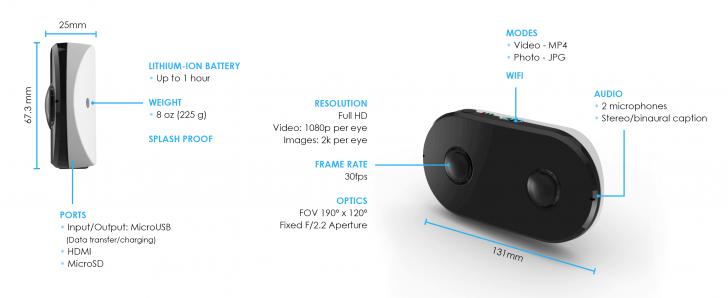

First to present on the Festival Pavilion was Lucid VR’s founder and CEO Han Jin. Lucid VR is preparing for the inevitable Virtual Reality takeover. The startup uses stereoscopy (aka 3D imaging) to enhance the illusion of depth within binocular vision, allowing users to create their own VR world through a headset such as the Oculus Rift or Google Cardboard via smartphone. The LucidCamfeatures 180° wide-angle lenses, which enables an active view of your recorded reality, and also provides spacial audio to enhance the experience. Jin and his team are looking to go beyond FaceTime and Skype, and are trying to connect families and friends across the globe by allowing immersion into a 3D reality, helping us feel as if we’re sharing the same 3D digital space with one another.

The second startup to present in The REAL Deal Startup Competition was Minds Mechanical, makers of proprietary metrology-based software solutions. Metrology (not to be confused with meteorology) refers to the scientific study of measurement, a much more time-consuming and cost-sensitive production step than you could ever imagine. Thus far, Minds Mechanical is focused on providing the aerospace with accurate big data analysis, process integration, and both software and hardware solutions for metrology. Co-founder Jacob Hockett explained to the audience and judge panel about how their metrology integration services and manufacturing software solutions can save manufacturing companies a lot of stress, time, and money, ensuring that their production parts are the exact size and weight needed for proper functioning.

Although these first two presenters were very heavily invested in the digital 3D world, the next two competing startups were heavily centered around 3D printing technology. I got the opportunity to sit down and speak to these next two presenters about what 3D printing technology and “Reality Computing” (aka the digitalization of the physical world) means to them and the success of their startup.

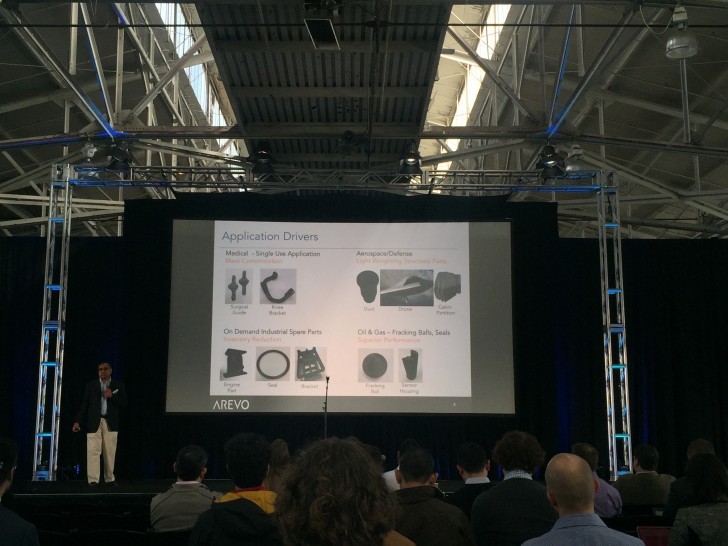

Hemant Bheda, founder of AREVO Labs, was focused on a new 3D printing material that they claim is five times stronger than titanium-based materials! I sat down with Hemant Bheda and AREVO Labs co-founder Wiener Mondesir after the The REAL Deal Startup Competition presentation to speak further about their Carbon Fiber Composite Materials, and also about how AREVO has taken what they call “two-and-a-half D printing” into true 3D printed form.

“The material we have developed is high temperature, chemical resistant, and has five times the strength of titanium. So, in conjunction with software that can do true 3D tool parts, we can now start creating objects that are as strong as metal and are much lighter,” Bheda explained to me. “The big applications we see are in aerospace because they want to have structures that reduce the weight of aircraft.”

Not only will 3D printing with AVEVO Labs’ Carbon Fiber Composite Materials make production parts much stronger than titanium and other metal-based materials, it will also, as 3D printing does best, help simplify the process as well.

“Another thing that happens is we start to see the assembly of 10-100 parts, but with 3D printing it can be a single part,” Bheda said. “That reduces the cost and simplifies the manufacturing process, so those are the reasons why we see a lot of interest from aerospace and defense companies, as well as oil and gas companies, because we can now make parts that are much stronger than before.”

In order to actualize the true strength and composition of their carbon fiber-based material, the AREVO team has to work on a more intelligent style of 3D printing, enhancing the typical X, Y, Z-axis printers into one with independently functioning robotic arms, which will allow for both sides of a surface to be built upon.

“All the existing printers out there have only X, Y, and Z; in order for us to do true 3D we needed more than three axes, so we looked at the robotic arm, which has six axie and is very mature. So, we utilized that as the mechanism for true 3D, the machine with the robotic arm is the 3D printer. The reason it is important is that the carbon fibers gives us strength, and even if you’re building a 3D object, if it constrains the fiber orientation only to one plane, we don’t get the best of it, we only get the most optimal performance if we let it orient in X, Y, and Z directions.”

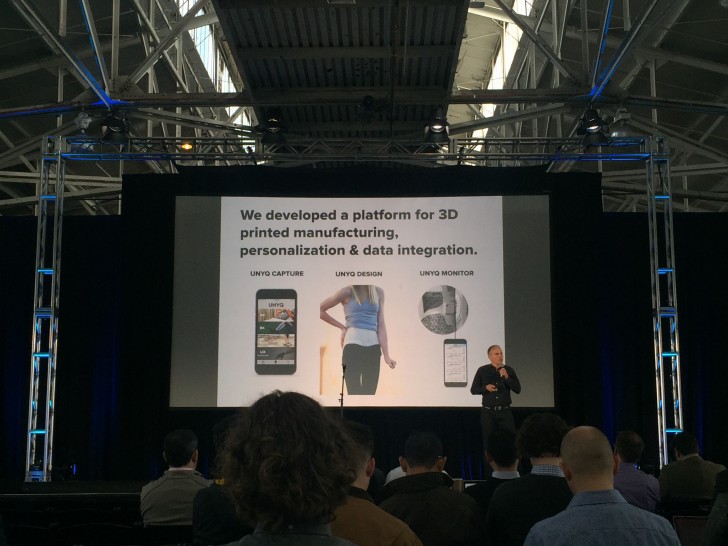

Last to present in The REAL Deal Startup Competition was UNYQ, the breakthrough prosthetic (and soon to be orthotic) startup that utilizes multiple 3D printing processes to create prosthetic covers that are both aesthetically and functionally driven. UNYQ’s founder, Eythor Bender, spoke about how their unique use of 3D printing has made prosthetic devices something for users to show-off rather than hide, and also discussed the new types of devices that UNYQ is currently experimenting with, including the 3D printed scoliosis brace and more.

“One thing was that we saw what was happening with other medical devices such as hearing aids, and seeing the early sign that [3D printing] could be very successful,” Bender explained to me. “We are adapting something to the body, and every body is different, we have certain products that we’ve been able to make right off-the-shelf, but some things are really hard to do because they must be custom, and mass customization in our field has not been possible until 3D printing came along. So I call our products the ‘leftovers’ of the bionic revolution.”

But while 3D printing technology is the important last step in the UNYQ production process, it is still fully dependent on image capturing. UNYQ doesn’t restrict itself to one type of image capturing or 3D printing process, and instead are continuously looking towards new developments to help enhance the old and innovate the new.

“The capturing process can be done in two ways, through scanning or photogrammetry, which we have been using more of; it has worked very well with the prosthetic covers,” said Bender. “Now that we are going more into scoliosis braces and prosthetics, we are moving more over to scanning, and 3D scanners are becoming cheaper and reaching a revolutionary moment right now, so time seems to be working with us.”

Eythor Bender then went on to discuss how UNYQ is open to multiple 3D printing processes too, and will continue to look towards to future to help expand their products into scoliosis and someday orthotic treatments too.

“We use two types of material, first we started with ABS for the prosthetic covers, we call that our style line because it needs some post-processing and we paint it in various colors, it’s a little more sensitive and used for aesthetic purposes. But we also have a performance line for prosthetic covers which are made from polyamide, they are laser sintered. While we now embark on the scoliosis braces, those will also be made with laser sintering, at least to begin with. What they will be made with down the road is unknown, there is so much development in 3D printing and it’s opening up a lot of opportunities for us to do this differently than laser sintering.”

The winner of The REAL Deal Startup has been announced, and the winner is… AREVO Labs! It seems that even in the face of the vast concept of Reality Computing, 3D printing technology still reigns supreme!