It seems like every day a new 3D printing material is released, but it’s not every day that that filament is from a worker-owned cooperative. So, when I learned that the Leartiker Polymer Institute – whose MyMat Solutions just released a new range of Nylon filaments – was a part of the Mondragon Corporation, I had to ask them about the Spanish company’s federation of worker cooperatives in Basque.

Josu Goikoetxea, from MyMat Solutions’ Market Development team, told me about Leartiker, Mondragon, and how it all works. “Leartiker is a privately owned nonprofit Polymer Institute that is part of Mondragon Corporation. The workers of Leartiker are the shareholders and owners of this entity, so they decide about the strategies, the addressed know-how goals and market challenges,” Goikoetxea explained. This means that the new Ultra Nylon and Soft Nylon filaments developed by MyMat Solutions are not just property of the company itself, but of its worker-owners, as well.

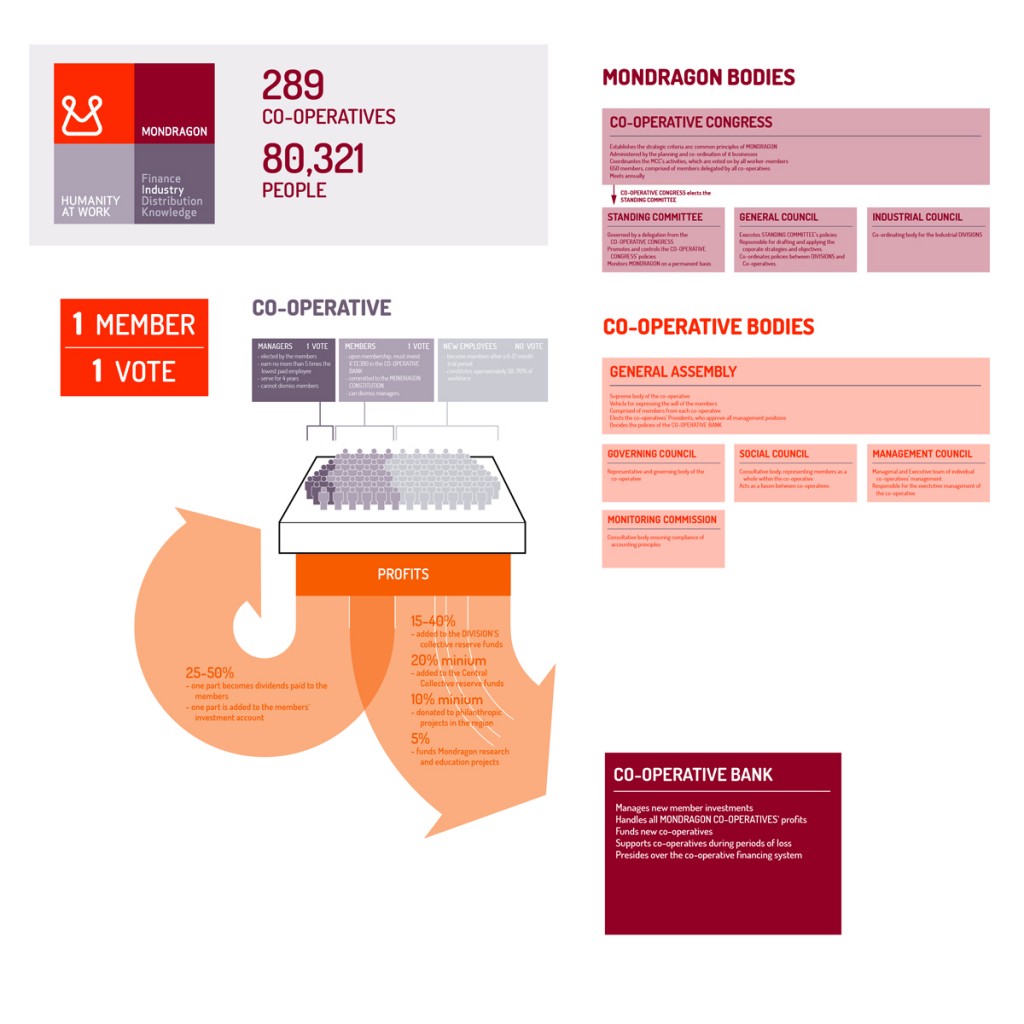

“Since the creation of the first cooperative, named Ulgor, in 1956,” Josu continued, “reverend Arizmendiarrieta (founder of the Mondragon movement and culture) and his disciples promoted and launched many companies and businesses that, nowadays, have arrived to be global companies that are leaders in their markets and sectors.” In fact, with more than 80,000 employees, the Mondragon Corporation posted €12 billion in revenue in 2013, divided among its Finance, Industry, Retail, and Knowledge sectors.

“Since those times, the creation of new economical activities around Mondragon Corporation and culture has been done with support and solidarity of enterprises well-established in their markets that have donated and helped with a percentage of their earnings, knowledge or technical expertise to the creation of these new businesses,” Goikoetxea says. “The main factor that moves these companies and workers to make these efforts is the goal to generate value and wellness in their surroundings, and make a society responsible, well-prepared, and professional because this is the way to maintain the culture and the identity for Mondragon Corporation values.”

The non-profit Leartiker Polymer Institute is, in some ways, like other non-profit research institutes in the world, such as TNO in the Netherlands or the RAND Corporation in the US. Goikoetxea explains that Leartiker works to create new value-added, stable, competitive jobs in order to promote social wellness in the region, often championing what they call “intrapreneurship”. Though the word may not be a familiar one, the world is familiar with the products of intrapreneurs when a company like Google creates a sub-organization, such as its ATAP experimental product group, and innovative technologies like Google Glass are released. Intrapreneurs work within a company, but with independence of entrepreneurs.

Getting back to MyMat Solutions, Josu says that their 3D printing initiative was an extension of these goals. “So, combining the Mondragon identity and culture with Leartiker’s core competencies around new material generation, advanced materials characterization, product and process design, and innovation management, MyMat was launched as a strong initiative that is called to be a key player in the creation, manufacturing and distribution of new value proposals for 3D printing and additive manufacturing sector. As a result, MyMat is a company held by Mondragon culture entrepreneurs concerned with the social wellness of their activity regions that create new, high-value and really useful materials for 3D printer professionals,lovers and users.”

In turn, MyMat released its first products, Ultra Nylon and Soft Nylon, with the former designed for use when high-mechanical strength and high-temperature resistance are necessary, like the automotive field. Soft Nylon, on the other hand, is meant for consumer goods and the like, for its wear resistance and flexibility. But, Goikoetxea assures me, these materials are only the beginning. “This just has started, don’t lose the thread.”

I asked Josu about how it felt to be a part of a worker’s cooperative in developing these new products, to which he responded, “Personally, I feel very involved in the launching and development of this new Mondragon initiative. My personal career has always been linked to innovation (10 years), market research, new technologies analysis and analysis of new business trends and identification to help my company and customer companies to achieve their goals in the launching of new entrepreneurial activities. So, I say it simply: I’m an entrepreneur and I enjoy and do my best to get the goal results, always following and looking for a state of wellness for our surroundings in the way that reverend Arizmendiarrieta’s guidelines show.”

Given the problems that have arisen as a result of the current economic system, including massive global inequality and environmental devastation, the Mondragon Corporation’s model has been touted as a possible alternative. Economist Richard Wolff, in particular, points to the fair wages of those working at Mondragon:

As each enterprise is a constituent of the [Mondragon Corporation] as a whole, its members must confer and decide with all other enterprise members what general rules will govern MC and all its constituent enterprises. In short, MC worker-members collectively choose, hire and fire the directors, whereas in capitalist enterprises the reverse occurs. One of the co-operatively and democratically adopted rules governing the MC limits top-paid worker/members to earning 6.5 times the lowest-paid workers. Nothing more dramatically demonstrates the differences distinguishing this from the capitalist alternative organization of enterprises. (In US corporations, CEOs can expect to be paid 400 times an average worker’s salary – a rate that has increased 20-fold since 1965.)

Despite the advantages that such a system might offer, Mondragon, like all companies, is not without its flaws. Perhaps the image of a worker-owned business may even mask some of these issues. For instance, David de Ugarte, Spanish cyberpunk and the founder of multinational worker co-op Las Indias, says of the corporation, “I understand the need of mythification of [Mondragon Corporation]… but from my point of view as a cooperative worker and a cooperativist militant for decades, its model -based in big industrial scales, intellectual property, inequality between the workers in the mainland, who are members and the workers in the third world who cannot become members, etc- is not a progressive model any more for the kind of worker’s cooperativism we need in this century.” This sentiment is echoed by Noam Chomsky, who also points out the discrepancy between Mondragon workers in Spain and those in third world countries abroad.

When I asked Josu about these concerns, he replied very candidly, saying that, as the company has grown from a local business to a global one, it has been difficult to implement the co-op structure abroad, “We have to take into account that the Mondragon cooperative model was created in the 50’s and it was a local initiative. It answered to the needs of a society that, in those years, was very poor. So, what I try to explain is that this model has a strong link to the identity of the local surroundings and the society. As the economy changed and the markets started to become international, the companies needed to be global and they started to promote new manufacturing sites, delegations and distribution plants all over the world…”

He adds, “Some markets, like automotive for example, are very difficult to operate. This market requires supplying companies with the creation of manufacturing sites closer to their global factories, if they want to get projects for their central site, based in the Basque Country. This is the reason why more and more companies create new facilities all over the world. But of course, the ‘cooperativization’ of global manufacturing sites is a really important topic that is treated in every global company inside Mondragon.”

But that doesn’t mean that haven’t tried. Companies within Mondragon did try to form cooperatives abroad, but the global economic crisis halted some of those attempts. Others, however, were successful in their attempts, Goikoetxea says, “It’s true that most of the international manufacturing sites are not cooperatives. In the early 2000, there were some companies with the mission to ‘cooperativize’ their factories abroad. These processes were stopped because of the global economic crisis and nowadays the process hasn’t been ‘relaunched’. On the other hand, in the last years there are some other entities that have successfully converted some of their manufacturing sites into a cooperative, like in the case of MAIER S. Coop. with its manufacturing site in Galicia called MAIER FERROPLAST. This process may be long in time but the improvement of flexibility and the global expansion of Mondragon will be also giving these steps.”

Josu also suggests that Mondragon hasn’t given up on this mission, saying, “This is a topic that is always on the minds of Mondragon workers and it is always cited and evaluated in the strategic plans, but we need to have clear and say clearly that it is not an easy topic to treat and solve. Mondragon is culture. Mondragon is identity. So, it needs to be well transmitted, well understood, and well assimilated.”

And, as Mondragon works to tackle these concerns, Josu believes that other co-ops are learning from the successes and flaws of Mondragon’s model. “Anyway, a lot of global entities learn from Mondragon model,” he continues, “For example, some of these explanations and data were obtained in a visit of Jon Santiago (the founder of New York City’s THINK cooperative, who studied MIT) that was made to Mondragon Headquarters in June, 2014. Responsible for the communication of these tops was Mikel Lezamiz, a person full of experience that enjoys showcasing Mondragon identity and culture and he showed us all the details around this. The Mondragon model is very useful to companies and enterprises to have a reference and feel the difficulties and key factors to have success on their own. ”

For MyMat, the company hopes to work with others around the world in a way that is beneficial for all parties involved. “From the MyMat point of view, we hope to be able to create a network involved with our model. We will collaborate with a lot of entities all over the world and the way we want to make business with them will be a partnership model. Real collaboration: cooperate adding value. The creation of some MyMat nodes in some countries is in our plans too. But there are some steps that we have to give previously.”

Josu’s response about individual Mondragon businesses’ attempts to cooperativize their factories abroad implies that all companies within Mondragon are not the same, with each operating independently. Therefore, individual co-ops within Mondragon may be more capable of enforcing standards abroad than others. Given Josu’s candidness, it seems that MyMat may be able to pull of its own attempts to implement Arizmendiarrieta’s vision globally, once it does tackle those first steps.

As we cover numerous companies putting out 3D printing products on a regular basis, it may be unfair to scrutinize one associated with a worker-owned co-op, without also scrutinizing management-owned businesses, too. But, because Mondragon is more of an anomaly than the norm, every aspect of the corporation is held under a magnifying glass. Imagine if we did the same for GE, a company that is covered continuously on this site for its fabrication of a 3D printed jet engine nozzle. In addition to a poor environmental record, including the design of the nuclear reactors that resulted in the Fukushima disaster four years ago, GE is notoriously anti-union, pays its CEO Jeffrey Immelt 139 times the average worker, and does everything it can to minimize its taxes to the US government (with some saying they pay nothing, some saying they even get a tax refund, and others saying they pay little).

I actually do occasionally try to point out these issues I have with the subjects of articles when I am aware of them, but am often subjected to flak in the comments that my opinions detract from the news, leading me to turn down the volume on my editorializing a bit. In some ways, those commenters may be right, if I did try to investigate every issue with every company putting out a product – from Airbus to Lockheed Martin – I would probably never get anything done.