As Makers, chemists, engineers, and professionals worldwide get a better grip on the potential of desktop FFF 3D printers, we are bound to see more and more advanced filaments that push the limits of what can be achieved. The Sinterhard Metal Filled Filament Project, now on Kickstarter, wants to do just that for metal composite filaments, by completing the development and starting production of Sinterhard Filaments.

The difference between Sinterhard filaments and other metal fills, such as those from colorFabb or Proto-Pasta, is that they can be used to produce full metal objects. This does not mean that Sinterhard’s material is a full-metal filament, but that it has a sufficient quantity of metal mixed in with its ABS and PLA that the 3D printed objects can first be “debinded”, without losing their shape, and then “baked” in a high temperature kiln to sinter together the metal particles.

Sinterhard intends to produce filaments using 316 Stainless Steel and Aluminum, both because they, respectively, have a moderate and a low sinter temperature, and because they collectively cover a very wide range of commercial applications. Furthermore, they are both available as a powder fine enough to ensure a high quality 3D printed part, that can be further machined after the sintering process.

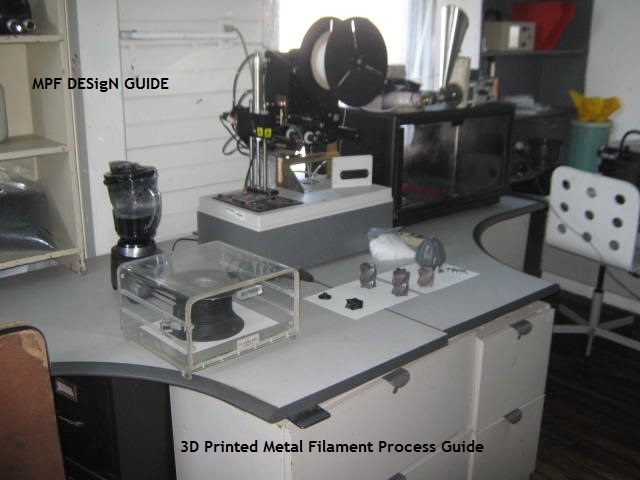

The goal is to use a 3D printer (and a furnace) to replace the Metal Injection Molding (MIM) process, a metal forming technique that uses injection molding equipment for manufacturing parts to tight tolerances. This process, which can replace other metal forming techniques, such as investment casting and machining, is typically used for small objects that weigh less than 100 grams. In this case, the project team has called its filament-based process MPF (Metal Printed Filament).

The post-processing for MPF is the same as MIM. In fact, MIM, also called Powder Injection Molding, uses a polymeric resin to carry the powder inside the mold. Likewise, the Sinterhard filament will form the metal 3D object. The “green” part is then debinded using a solvent (which could be acetone for ABS) or by thermal evaporation. What remains is the “brown” part: a soft, low density metal object, which is placed in the furnace to yield the final component. This is, of course, what should happen, but those familiar with this process know that successfully sintering metal components in a furnace is no easy task.

Sinterhard knows this particularly well because the team is made up of furnace experts with over 30 years experience. They will share all of this experience by releasing an open source guide on creating metal objects through MPF. In fact, their next goal, if the filament project is successful, is to create a specific furnace for sintering of filament based metal products.

If you think that filament-based, full-metal objects have a future, you might want to contribute to the campaign and fund it, perhaps by purchasing 2 lbs of 316 Stainless Steel or Aluminum (with in ABS or PLA, 1.75 or 3 mm), all for a $100 dollar pledge. If they pass it they will invest in researching other powder for MPF, and that sounds to me like a pretty good reason to support them.