A project conducted by a team of researchers from the University of Sydney, and published in the journal of Optics Letters, built a functional, dual absorption and fluorescence spectrometer combining a smartphone and its set of electronic sensors (and CMOS chip) and a 3D printed enclosure. It is not the first time that we find basic, desktop 3D printing being used in high-level university projects and the trend is getting stronger in many fields.

Absorption and fluorescence spectrometry are complementary techniques for analyzing a “spectrum” of data. The first measures the absorption of radiation, as a function of frequency or wavelength, due to its interaction with a sample. The second is a type of electromagnetic spectroscopy that analyzes a sample through a beam of light, usually ultraviolet light, exciting the electrons in molecules of certain compounds and causing them to emit light.

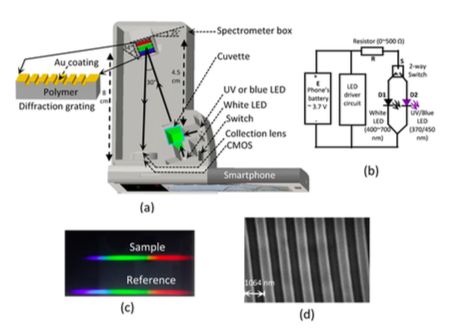

The key challenge for the scientists was to build a “lab-on-a-phone” that was completely self-contained, with the phone’s battery, which can easily be charged anywhere with access to electricity, powering the entire system. The dual functionality also contributed to further reducing the cost of the device, while increasing the range of possible applications. While the spectrometer case that fits over the smartphone was 3D printed in regular ABS the “disperse elements” within it, which make the analysis possible, were produced using a low-cost nano-imprinting technology.

Th absorption measurements are made using the smartphone camera’s white-light LED, which was deemed to have sufficient irradiance and spectral breath for several applications. For fluorescence measurements, the University of Sidney team demonstrated the simple integration of low-cost VIS (as in “visible light) and UV (as in ultra-violet) LEDs into the phone, allowing dual (or trifold) measurements to be undertaken with one single instrument.

In this case, using 3D printing allowed the scientists to develop a tool which did not exist at a fraction of the cost. If a single, ope- source 3D printed pump can generate several millions of dollars of value, as estimated by Michigan Tech researchers, imagine what this (and other projects like this) can do in the long run.