Improving the delicate process of 3D printing features smaller than the width of a human hair has, as you can imagine, many parameters to consider. To widen the applications of the method, new materials have to be created. And increasing the size of parts can come at a cost to time.

At Lawrence Livermore National Laboratory (LLNL) researchers have uncovered a new piece to the two-photon lithography puzzle that maximises the possibilities of the technology, especially for use in medicine.

Two-photon lithography “on its head”

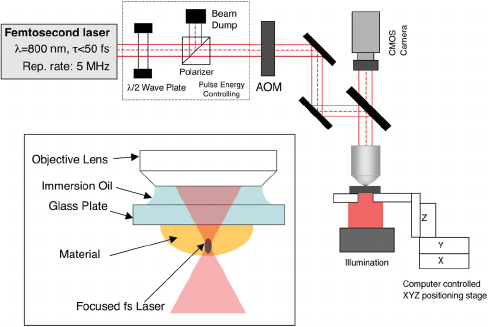

Two-photon lithography can 3D print features that are much smaller than the resolution of laser beam curing source. This is made possible by a lens/glass plate arrangement that filters the laser into a fine focal spot.

Two-photon lithography machines typically 3D print from the bottom-up. In LLNL’s research, this process is literally turned on its head, enabling what is termed “dip-in

laser lithography.”

Dip-in laser lithography

According to Sourabh Saha, R&D engineer at LLNL, “Most researchers who want to use two-photon lithography for printing functional 3D structures want parts taller than 100 microns.” In typical two-photon lithography, length is limited due to a short space in-between the material vat, and the glass-plate used to focus the laser.

By contrast, in dip-in laser lithography, liquid photoresist feedstock is put directly on the lens, and the laser is focused through the material.

As the laser refracts when it enters the photoresist material, and the immersion oil needed for the lens, the researchers had to figure out how to match the “refractive index” of both liquids, “so the laser could pass through unimpeded.”

Saha adds, “With these index-matched resists, you can print structures as tall as you want. The only limitation is the speed.”

“It’s a tradeoff, but now that we know how to do this, we can diagnose and improve the process.”

Experiments in Saha et al’s research were conducted using a Photonic Professional GT laser lithography system from Nanoscribe GmbH – the leading provider to two-photon lithography machines. As of September 2012, Nanoscribe has had a patent-pending application for its own dip-in laser lithography (DiLL) process.

Better for medical

By optically tuning the photoresist to match the oil, the researchers were also able to create a material that is more susceptible to CT x-rays, making it easier to identify and characterize the internal geometry of a 3D printed part. As a result, two-photon lithography 3D printed parts using the dip-in method are more suited to medical applications than their “bottom-up” counterparts.

Incidentally, medicine is the area that two-photon lithography is showing the most prominence. Nanoscribe Photonic Professional GT systems are used for medical research at, among others, the Max Planck Institute for Intelligent Systems, George Washington University and IFW Dresden.

One piece of many

“It’s a very small piece of the puzzle that we solved,” concludes Saha, “but we are much more confident in our abilities to start playing in this field now,”

“We’re on a path where we know we have a potential solution for different types of applications. Our push for smaller and smaller features in larger and larger structures is bringing us closer to the forefront of scientific research that the rest of the world is doing.”

Radiopaque Resists for Two-Photon Lithography To Enable Submicron 3D Imaging of Polymer Parts via X-ray Computed Tomography is published in the ACS Applied Materials & Interfaces journal. It is co-authored by Sourabh K. Saha, James S. Oakdale, Jefferson A. Cuadra, Chuck Divin, Jianchao Ye, Jean-Baptiste Forien, Leonardus B. Bayu Aji, Juergen Biener and William L. Smith.

Nominate the best research teams of 2017 in the second annual 3D Printing Industry Awards here.

Subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook here.

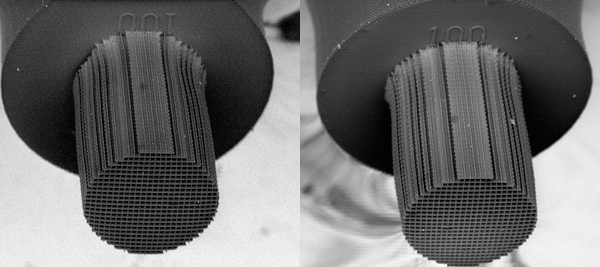

Featured image shows a lattice 3D printed using LLNL’s dip-in laser lithography approach. Photo by James Oakdale/LLNL.