A team of researchers from the Ulsan National Institute of Science and Technology, South Korea, have produced a walking starfish-shaped soft robot using 3D printing and sacrificial molding.

The five limbs of the starfish, while not obvious at first, are complex tensegrity structures. Acting like tendons in a biomechanical system, these structures are programmable with varying stiffnesses and flexibilities, meaning they can be actuated to induce controlled movements. In this case, the actuation mechanism is a magnetic tendon – one that can cause the rest of the tensegrity structure to contract and relax to move the robot in a certain direction.

What are tensegrity structures?

Tensegrity structures have become synonymous with artistic desk toys in recent years, but the same principles can be applied to more functional applications. Tensegrity, or tensile integrity, describes systems that look like they are under compressive loading, but are actually completely supported by tensile (pulling) forces.

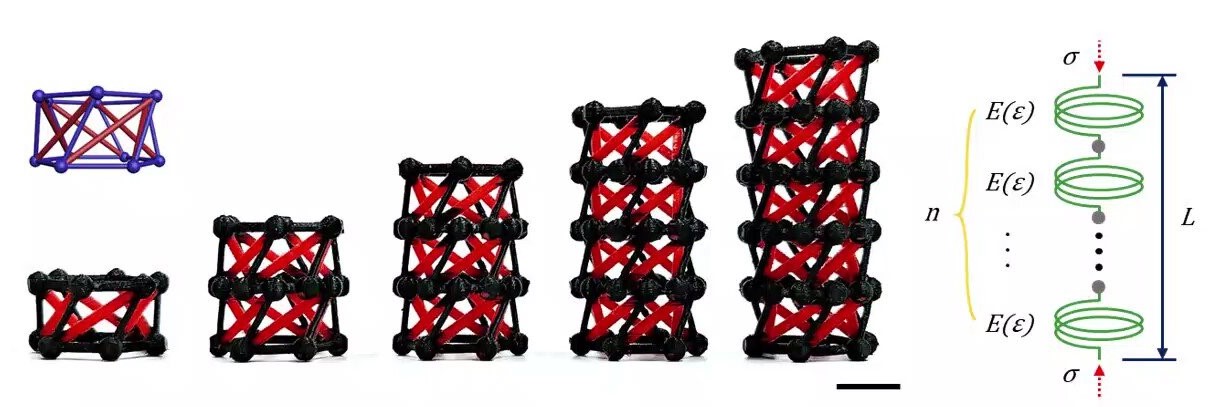

With a combination of stiff struts and a multi-directional network of tendons, tensegrity structures can provide both structural integrity and flexibility with some clever tendon manipulation. They exhibit high stiffness-to-mass ratios, controllability, and large scale deployment potential. By also integrating smart, or functionally graded, materials into tensegrity structures, they can be further functionalized with improved controllability.

Seeing as the structures require a relatively delicate balance to be operational, their assembly is usually a highly manual process so manufacturing approaches capable of producing complex 3D tensegrities are rare. However, the structures are abundant in natural systems like the human musculoskeletal one, so the team thought investigating them might prove valuable in the development of bio-inspired robots.

3D printing the starfish robot

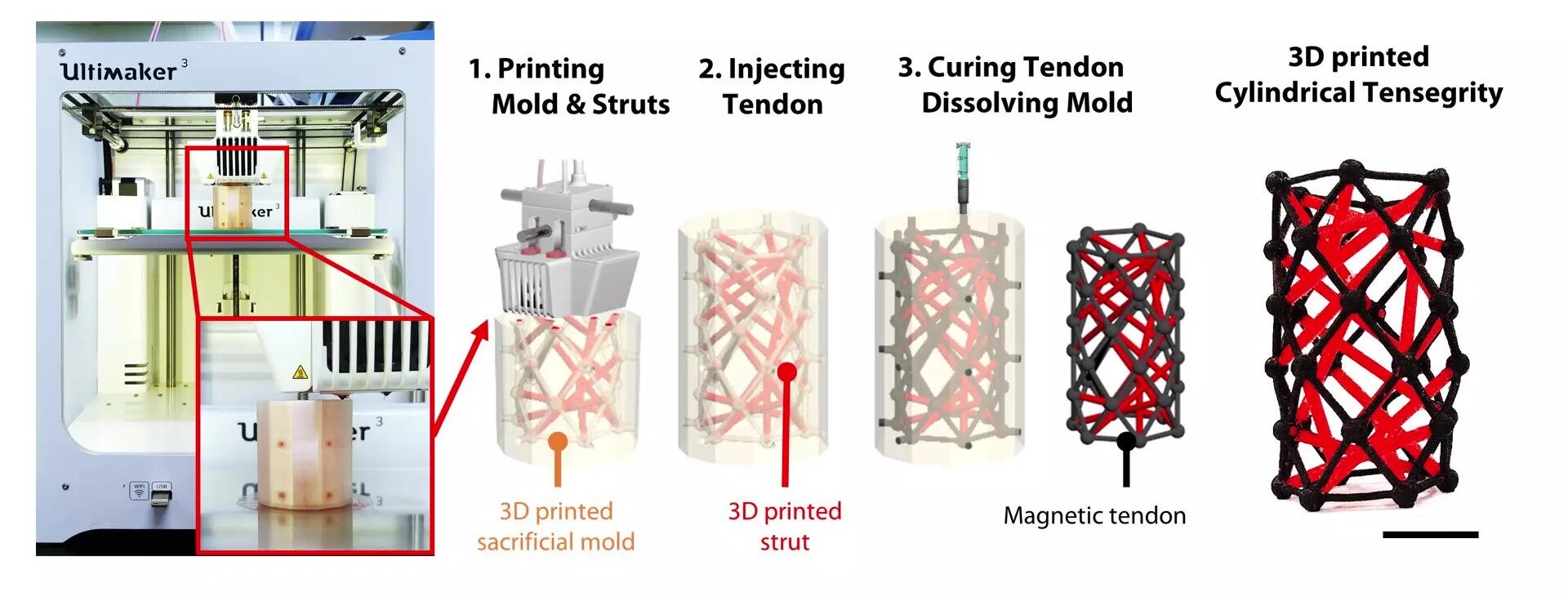

The methodology devised by the research team was actually a very intelligent one. They used a commercially available Ultimaker FDM printer to fabricate a sacrificial mold for the tendons of the structure, while also printing the isolated rigid struts (black beams) within the mold. The mold, once injected with the contractible ‘smart material’, would produce the continuous internal channel of tendons (red beams) found in the tensegrity structure. Once that smart material solidified, the sacrificial mold was dissolved and all that was left was the softer smart tendon network integrated with the rigid struts.

This cycle of ‘print, inject, dissolve’ was repeated four more times for the remaining limbs, and the five cylindrical structures were assembled around a central body to form the starfish shape. With magnetic actuation, the red tendons in each limb could be contracted and relaxed in coordination with each other to move the robot in any direction.

The team believes itself to be one of the first to propose a simple method of 3D printing complex tensegrity structures, and has stated that the novel design principle could pave the way for a whole new approach to soft robot production.

Further details of the study can be found in the paper titled ‘3D-printed programmable tensegrity for soft robotics’. It is co-authored by Hajun Lee, Yeonwoo Jang, Jun Kyu Choe et al.

The 3D printing of soft robotic devices garners more attention with every passing year. A team of researchers from UC San Diego recently developed a new method of 3D printing liquid crystal elastomers (LCE), one that enables functionally graded properties simply by varying the printing parameters. With potential applications as a novel actuating material, the LCE’s stiffness and contraction capabilities can be closely controlled with heat during and after the printing process.

Elsewhere, in Asia, researchers have recently 3D printed a soft robotic finger that is powered by an embedded single-electrode triboelectric curvature sensor (S-TECS). It can sense bending curvature at ultralow working frequencies without the need for any external power source.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed starfish robot. Photo via UNIST.