A coalition of researchers from Zhejiang University of Technology, Tianjin University, Nanjing Institute of Technology, and Ritsumeikan University, have used 3D printing to create a soft robotic finger.

Powered by an embedded single-electrode triboelectric curvature sensor (S-TECS), the additive digit can sense bending curvature at ultralow working frequencies, without requiring an external power source. The device was produced as a proof of concept that multi-material 3D printing can not only be used to fabricate soft actuators, but also functional sensors. The researchers hope the innovation will pave the way for a simple and fast manufacturing process to produce controllable soft robotics.

The unique approach to building a robotic finger

Robotics constructed using a mixture of soft materials and compliant structures are increasingly providing solutions to challenges caused by aging populations. As soft robotic research advances and new manufacturing methods are developed, human-robot interactions are becoming safer and opening new applications for the technology. It is now possible for example, to directly print soft robots with an air-tight complex structure and hard components. This development has led to innovations such as the Wyss Institute’s 3D printed jumping robot produced in 2015.

Other soft robotics projects, like that of the Wyss team, have integrated soft sensors based on piezoelectric, conductive, magnetic, and organic optical materials into their soft robotics designs. According to the researchers though, these sensors can have drawbacks such as lengthy prototyping times, unstable cable connection, complicated system assembly, and difficulties with system integration.

As a result, the research team opted to use triboelectric sensors. This type of component offers high stretchability and sensitivity, allowing the robotic finger to actively perceive and sense its deformation or response in-real time. Using 3D printing within the process also enabled the team to use multiple materials, and take advantage of a one-step printing process with shortened prototyping times. Constructed through the combination of a triboelectric curvature sensor and a stretchable electrode, the researchers’ S-TECS sensor managed to avoid the same integration complexity as previous projects.

Integrating S-TECS sensors into 3D printed parts

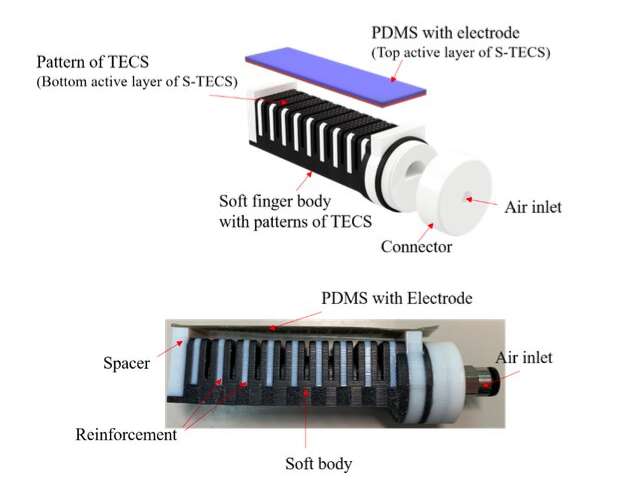

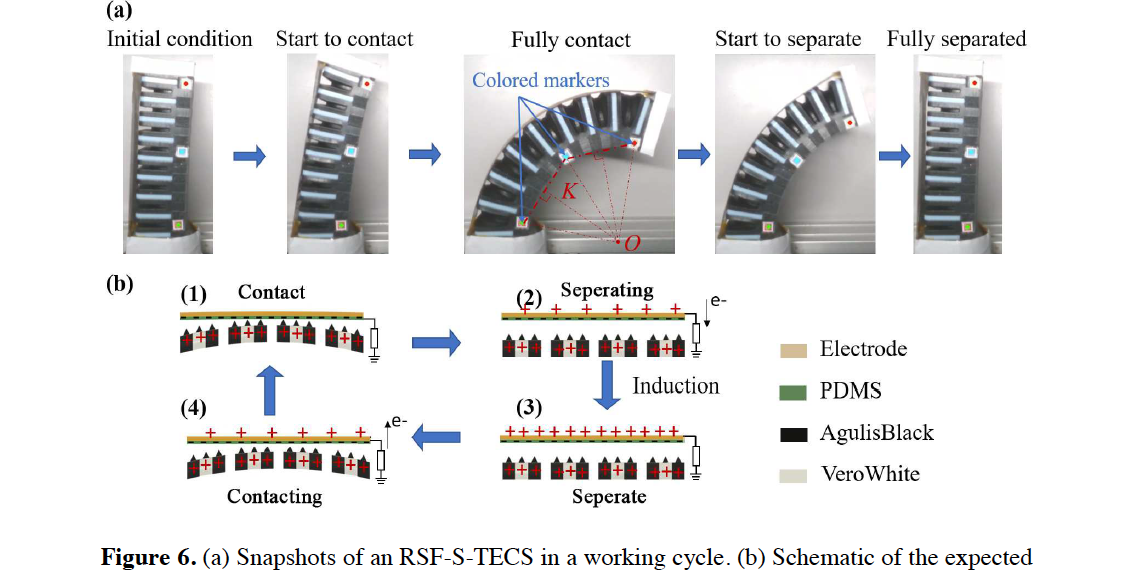

The device’s main body consists of nine inflation chambers connected to a main airway, with each chamber featuring a rectangular shape to provide a flat surface for S-TECS patterns to be printed on. The hard-reinforced chambers have a width of 2 mm, with two spacers at both ends to support the top layer of S-TECS, and maintain a height of 3 mm between the two layers. The additive digit can only bend in one direction according to its chamber configuration. When the finger bends, the top layer of the S-TECS starts to approach the bottom layer, until it makes full contact, activating contact electrification and generating electricity.

The device was produced using a Stratasys multi-material Objet350 3D printer in two separate parts: the reinforced soft main body and the connector. Patterns of S-TECS were directly printed onto the top surface of the finger body to simplify the total fabrication process, and to reduce production time. The triboelectric layer and soft body of the device were produced using the rubber-like AgilusBlack printing material, as it demonstrated a tensile strength of 2.75 MPa, and elongation at break of 250%. Curing was carried out at room temperature for 24 hours, and once the finger’s 3D printed parts were screwed together, and the S-TECS attached by silicone adhesive, the assembly was complete.

The researchers tested the sensor’s performance under different conditions by changing the surface configuration, forces applied to it, and operational frequencies in an automated setup. Integrating the sensor with different soft materials was not found to reduce the flexibility and adaptability of the overall robotic system. In addition, the sensors proved to be capable of measuring a finger curvature up to 8.2 m-1 under an ultra-low working frequency of 0.06 Hz.

Testing not only proved the effectiveness of the S-TECS as a self-powered curvature sensor, but also the feasibility of creating soft robotic structures with triboelectric layers using multi-material 3-D printing technology. The researchers concluded that the method had the potential to be utilized in future robotics applications that use advanced sensing capabilities.

Additive manufacturing and soft robotics

3D printing has been utilized to create soft robotics with a wide array of applications ranging from the aerospace industry to medicinal purposes.

Researchers from New York’s Cornell University developed a 3D printed soft robotic muscle capable of controlling its internal temperature through perspiration in January 2020. Its soft fingerlike actuators could retain water and respond to temperature to cool itself down.

A pair of NASA researchers successfully used 3D printing to produce a soft robotic actuator in May 2019, a key component for animating and controlling a robot’s moving parts. The research was part of a broader investigation into potential soft robotic applications in space.

Rutgers University-New Brunswick researchers created a new hydrogel 3D printing material in May 2018 that was so flexible, it could be made to walk like a human being. Developed for applications in the medical industry, the material could be used to deliver drugs to target parts of the body, reducing the risk of damage to a patient.

The researchers’ findings are detailed in their paper titled “A soft robotic finger with self-powered triboelectric curvature sensor based on multi-material 3D printing.” The study was published in the Science Direct Journal and co-authored by Mingzhu Zhu, Mengying Xie, Xuanming Lu, Shima Okada, and Sadao Kawamura.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed robotic finger, which is constructed out of nine layer chambers (pictured). Photo via Science Direct.