Recently, we’ve received a little flak for covering a certain pen-like piece of tech that may or may not be considered 3D printing. There’s definitely a divide of strong opinions, but probably a larger proportion of people that are not particularly bothered either way. However, at 3DPI it is also increasingly evident that some folks out there are driven by SEO, and may just be inserting the phrase “3D printing” into their PR and blog posts to draw internet traffic. A lot are obvious, some, not so much. Before dismissing projects as non-legitimate forms of 3D printing or additive manufacturing (AM) you have to work within a definition — it’s obvious many people have variations — and even then, interpretation leads to debate. But, for the sake of argument, and in the context of this article let’s use Wikipedia’s definition here:

Additive manufacturing or 3D printing is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes. 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes).

Based on that definition, for a production method to be considered 3D printing, it requires 1. the translation of a digital model into a solid object, 2. a layer by layer process, and 3. that it’s not subtractive. Now, let’s consider a recent story from MIT and figure out if it fits into the above definition.

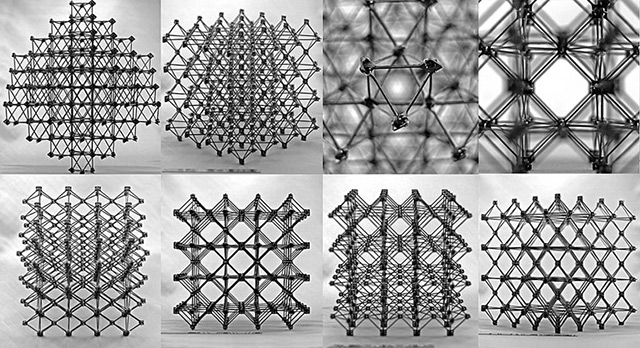

Postdoc Kenneth Cheung and director of MIT’s Center for Bits and Atoms, Neil Gershenfeld, have developed a new construction process they say is inspired by 3D printing. In trying to answer the question, “Can you 3D print an airplane?” the researchers decided that AM was probably not the most practical method for constructing an airplane. Instead, they are in the process of developing interlocking, chainmail like structures that will form the basis for building blocks. Rather than printing them, they are considering the use of, as the MIT news blog puts it, “an assembler robot that can crawl, insect-like, over the surface of a growing structure, adding pieces one by one to the existing structure.” “Insectlike”? Count me in!

The researchers have admitted that they were simply “inspired” by 3D printing and are making no claims that what they’re doing is 3D printing. But, I began to wonder, is a terrifying robot that crawls around putting flat pieces together a form of additive manufacturing? If it’s a robot, then, surely, it will be crawling around based on instructions from a computer that will rely on a digital model. The disturbing machine will, also, most likely build from the ground up. And it will be adding and not subtracting. To me, this creature of unknowable horror, is sort of like an independent print head that can build up successive layers based off of a 3D model. It’s not sintering or extruding the lattice structures, which will be mass-produced. Really, it’s not producing the material itself, but the ABS of a FDM machine and the actual powder that’s fused with SLS are not, in themselves, formed by printing. In my eyes, MIT’s robo-demon assembly process is a 3D printer.

Once we’ve reached the end of existence, it becomes clear that we’ve gone too far and should have restrained ourselves. For the sake of simplicity, easy conversation and mutual understanding, let’s step back a bit. Let’s allow such examples as the silk worms, the human hands, the insectoids to exist in the ongoing dialogue surrounding 3D printing as examples to enrich the creative process, challenge our conceptions about the world and to help us think of new ways to additively manufacture. But maybe we shouldn’t call them 3D printing just yet.